Commission, March 16, 2015, No M.7479

EUROPEAN COMMISSION

Judgment

KINGSPAN/ STEEL PARTNERS

Dear Sir/Madam,

Subject: Case M.7479 - KINGSPAN/ STEEL PARTNERS

Commission decision pursuant to Article 6(1)(b) of Council Regulation No 139/20041 and Article 57 of the Agreement on the European Economic Area2

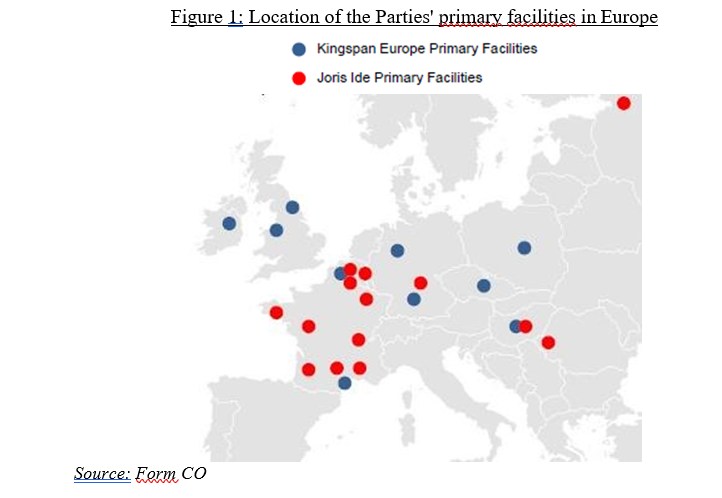

(1) On 9 February 2015, the European Commission received a notification of a proposed concentration pursuant to Article 4 and following a referral pursuant to Article 4(5) of the Merger Regulation by which the undertaking Kingspan Group Plc ("Kingspan", Ireland) acquires within the meaning of Article 3(1)(b) of the Merger Regulation sole control of the whole of Steel Partners NV/SA ("Steel Partners", Belgium) by way of purchase of shares.3 Kingspan is hereinafter referred to as "the Notifying Party". Steel Partners is hereinafter referred to as "Joris Ide" or the "Target". Kingspan and Steel Partners are collectively referred to as the "Parties".

1.THE PARTIES

(2) Kingspan is active in the manufacturing and distribution of a range of construction products, such as raised access floors, steel frame and timber frame offsite solutions, environmental and renewable fuel and water storage solutions, insulated panels, rigid insulation boards and hot water systems. Kingspan had revenues of EUR 1.9 billion in 2014, of which 59% comes from insulated panels.4

(3) Steel Partners is mainly active through its holding of the Joris Ide Group of companies in the manufacturing of sandwich panels and construction sheets with manufacturing facilities in Belgium, France, Germany, Hungary, Romania and Russia.

2.THE OPERATION

(4) On 26 January 2015, the Parties have signed a Sale and Purchase Agreement according to which Ever 2479 Limited, a wholly-owned subsidiary of Kingspan, acquires all the shares in Steel Partners.

(5) Steel Partners is currently owned by Ergon ([…]%), Bremhove NV/SA ("Bremhove") ([…]%) and [holding company X] ([…]%). All shares of [holding company X] are owned by Ergon, Bremhove and certain senior managers ([…]).

(6) On the completion of the transaction, both Ergon and Bremhove will sell all their shares in Steel Partner, […],5 to Ever 2479 Limited. Consequently, Ever 2479 Limited will hold 91% of the shares in Steel Partner directly and […].

(7) Kingspan will therefore acquire sole control over Steel Partners, through its wholly- owned subsidiary Ever 2479 Limited. The transaction therefore constitutes a concentration within the meaning of Article 3(1)(b) of the Merger Regulation.

3.EU DIMENSION

(8) The Parties' combined worldwide turnover was EUR 2 225 million in 2013. The Parties' combined worldwide turnover does not therefore exceed EUR 2 500 million and the thresholds of Article 1 of the EU Merger Regulation are not met. On 18 December 2014 the Notifying Party informed the Commission in a reasoned submission that the concentration was capable of being reviewed under the national competition laws of several Member States6 and requested the Commission to examine the transaction. None of the Member States that were competent to examine the concentration indicated its disagreement with the request for referral within the period laid down by the Merger Regulation.

(9) The notified operation therefore is deemed to have an EU dimension pursuant to Article 4(5) of the EC Merger Regulation.

4.RELEVANT MARKETS

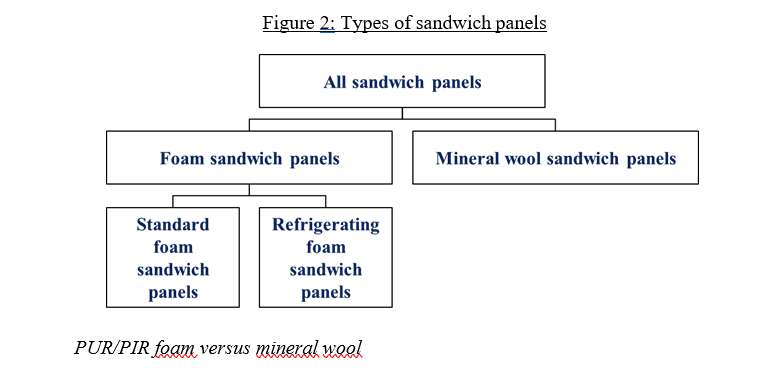

(10) The Parties' activities overlap in the production and supply of (i) sandwich panels, and (ii) construction sheets (single skin profiles).

4.1.Relevant Product Markets

4.1.1.Sandwich panels

(11) Sandwich panels are used in the construction industry mostly as cladding or roofing, for example in industrial and commercial buildings. Panels can also be used for specialty applications, such as cold stores and clean rooms. Sandwich panels are made of an insulating core, mainly polyurethane (PUR) foam, polyisocyanurate (PIR) foam or mineral fibre (also known as mineral wool, or rockwool), covered by two steel facings.

(12) Sandwich panels vary in particular according to: i.end use (roofing, walls, cold store etc.); ii.insulation properties: this is in particular determined by the type of insulation core (PUR/PIR foam core has much better insulation properties than mineral fibre), and its thickness. For example, as cold store sandwich panels (also called refrigerating panels) require superior insulation properties, only foam core is used, and their thickness typically from 60mm to 200mm (but possibly more) may be double to that of standard foam panels (typically from 30mm to 100mm)7; iii.fire resistance: mineral fibre sandwich panels are non-combustible and are able to meet highest fire safety standards. While foam core panels generally have lower fire resistance than mineral fibre panels, PIR foam panels have been developed due to their superior fire resistance properties compared to PUR foam panels.

(13) Sandwich panels are sold through different channels, which can be roughly divided into direct sales to end-customers and sales through distributors. Direct sales are made to customers including investors/end-users of the building, construction companies or specialised builders (such as cold store installers). For large projects, sales efforts may include brand promotion to decision makers, such as architects and engineers, with the aim of influencing project specifications in favour of a certain sandwich panel brand (so called "prescriptions").

4.1.1.1.Past decisional practice

(14) In a previous decision,8 the Commission found that sandwich panels constitute a separate relevant market. The Commission also suggested that a distinction should be made between (i) standard sandwich panels and (ii) refrigerating panels, but ultimately left the market definition open. Refrigerating panels were found to be primarily used to build cold storage facilities in the food and pharmaceutical industries, have specific properties (better insulation and resistance to fire, humidity, chemical agents, and different esthetics) and were significantly more expensive than standard sandwich panels.

4.1.1.2.The Notifying Party's arguments

(15) The Notifying Party considers that further segmentation of sandwich panels by end-use application or by product characteristics is inappropriate in this industry. Segmentations, in particular, between roof9 and wall panels, or by thickness of the panel, are not appropriate for a range of reasons.

(16) Firstly, customer demands vary widely and most orders are ad hoc and bespoke given that customer order panels in different shapes, forms and sizes for the specific needs of the relevant construction or renovation project for which the panels are destined.

(17) Secondly, all of the panels are produced on the very same production lines so there is complete supply-side substitutability for these products. Importantly, there is no specialisation of suppliers for any specific type of panel: all suppliers can and do provide their customers with a wide range of sandwich panel products. Such flexibility is inherent in the production lines that are owned by all suppliers; thus each can compete for the same customers for a broad range of products and product characteristics.

(18) The Notifying Party also deems that a distinction may be made between mineral fibre and foam sandwich panels, but that this distinction is not relevant in the present case. These panels can and are being used for the same end-use applications. Historically, whilst mineral fibre panels were occasionally preferred over foam panels due to their better fire resistance (and acoustic) properties, in recent years the technology of foam sandwich panels has improved to such an extent that this difference has diminished. Finally, the demand for mineral fibre panels is relatively small, and is static if not declining.

4.1.1.3.Commission's assessment

(19) The investigation confirmed that, for the purposes of defining a relevant product market, sandwich panels can be distinguished from other building materials, such as concrete and build up solutions (combining construction sheets and insulation material on site), which only pose a limited constraint. 10

(20) Within the sandwich panels universe, the investigation examined whether the market could be further subdivided (i) according to the type of insulation core (PUR/PIR foam versus mineral fibre), (ii) according to the end-use of foam panels (standard foam panels for walls and roofing versus cold store (refrigerating) panels).

(21) The investigation suggests that there is limited degree of substitutability between foam core sandwich panels and those with mineral fibre core: i.Based on the differences in product characteristics (notably largely diverging fire resistance and insulation properties), respondents confirm that mineral fibre panels and foam panels are different products which meet different needs. Foam panels have far better insulation features and are cheaper than mineral fibre panels, are easier to mount, serve most of the customers, but have inferior fire resistance and acoustic insulation characteristics. In case of a price increase, customers are unlikely to switch from mineral fibre panels to foam panels, or vice-versa.11 In a contemplated switch from foam panels to mineral fibre panels, the thickness of a mineral fibre panel would need to be almost double than that of a foam panel to compensate for the inferior insulation properties of mineral fibre core. As a consequence, this would not only imply that the price for mineral fibre panels would be higher than for comparable foam panels, but would require in addition adaptations to the building design as well as higher installation costs. Therefore, the costs of switching from foam to mineral fibre panels would largely exceed a possible 5-10% price increase for foam panels. Switches from mineral wool to foam panels are also an unlikely reaction to a price increase. This is driven by project specifications, in particular concerning required fire resistance (and to a lesser degree acoustic insulation) characteristics of the materials. Mineral fibre panels are typically used for projects with strict fire safety requirements, where, in case of a price increase, switching to foam panels is not an option.12 ii.Production of sandwich panels cannot be easily switched from foam core to mineral wool core, or vice versa. There is only a minor number of producers with combi lines, which are able to produce both foam and mineral fibre core panels at will. In contrast, the large majority of existing production lines can only produce either foam or mineral fibre panels.13 Installing a new line would cost EUR 5-10 million and would take 2-3 years. Producers confirmed that retrofitting foam machines to produce fibre core panels (and vice versa) is possible, but costly, and may imply lead times of up to 12 months, machine downtime of 1 month and an investment in a range of EUR 0.5 - 2 million. Costs are even higher when adapting mineral fibre machines to produce foam core panels.

(22) However, as the competitive assessment of the transaction does not give rise to serious doubts as to its compatibility with the internal market under any plausible product market definition (see sections 4.2.1 and 5.1), the exact product market definition can be left open in this case.

Standard foam panels versus refrigerating panels

(23) Within the foam core sandwich panels segment, an even narrower split could be considered based on their end-use application: (i) standard foam panels (used in walls and roofing) and (ii) refrigerating panels (used in cold stores). The investigation showed that these panels were substitutable to a certain degree: i.According to the majority of competitors, refrigerating panels are distinct products from standard foam panels and satisfy different needs. Correspondingly, customers largely confirm that they would not substitute refrigeration panels for standard foam panels, or vice versa, in case of a price increase.14 The main difference is that refrigerating panels require superior thermal insulation properties (translated into higher thickness of up to 250mm compared to standard panels which normally go up to 100mm). They are also said to require different product certification, different surface finishing (lower esthethic and weatherproofing features), and better joints/air thickness characteristics. For this reason, standard panels are normally not used for refrigeration ends and vice versa (except in regions with very cold climate). Contrary to the Notifying Party's assertions, certain suppliers indicated that refrigerating panels are more expensive than standard foam panels. Refrigerating panels typically use a different route to market. While standard building panels are sold directly to construction companies or distributors, refrigerating panels are marketed via operators specialised in mounting cold stores. ii.Respondents generally confirmed that standard foam panel production lines can be used to also produce refrigerating panels (and vice versa) without a major investment.15 This said, there are businesses specialised in producing refrigerating panels16 and others which claim not to be equipped to produce certain, or any, refrigerating panels.

(24) As the transaction does not raise serious doubts as to its compatibility with the internal market even under the narrowest plausible product market definitions for, respectively, refrigerating foam panels and standard foam panels (see section 5.1), the exact product market definition can be left open in this case.

4.1.2.Construction sheets

(25) Single skin construction sheets are used in the construction industry for cladding, roofing and decking. These products do not have thermal insulation properties like sandwich panels. Single skin construction sheets are made from cold rolled galvanised or colour-coated flat carbon steel and come in a variety of types. These can be among other shapes corrugated, ribbed or flat.

4.1.2.1.Past decisional practice

(26) In its recent SSAB/Rautaruukki decision17, the Commission has found that there may be separate markets for construction sheets by end-use application, but ultimately left the market definition open. The Commission noticed (i) that there is no great difference in price between different applications and (ii) that there is a high level of supply-side substitutability between construction sheets. Demand-side substitutability has also been acknowledged by market participants concerning sheets for roofing and those for cladding.

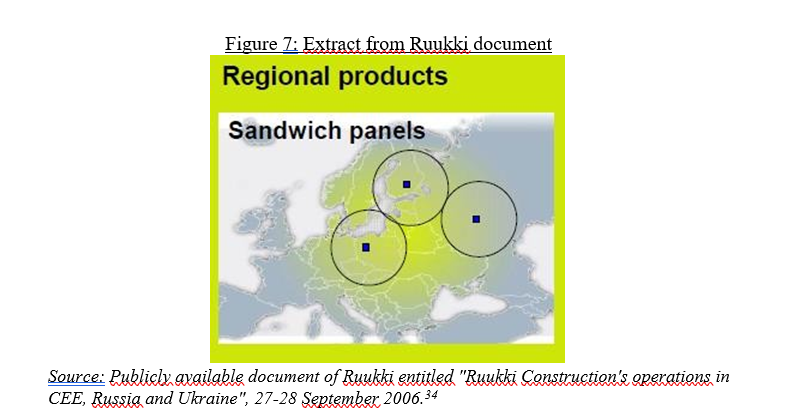

4.1.2.2.The Notifying Party's arguments

(27) The Notifying Party submits that there is no need to further divide the construction sheet market by end-use application. The Notifying Party notably argues that the Commission did not reach a definite conclusion in its previous decision and that it acknowledged a degree of supply-side substitution. The Notifying Party explains that a same production line can make many different types of sheet by changing the rolls on the equipment.

4.1.2.3.Commission's assessment

(28) As the competitive assessment of the transaction (see section 5.2) does not raise serious doubts as to its compatibility with the internal market under any plausible product market definition, the exact product market definition can be left open in this case.

4.2.Relevant Geographic Markets

4.2.1.Sandwich panels

4.2.1.1.Past decisional practice

(29) In its 1999 decisions18, the Commission considered the geographic scope of the sandwich panels to be Community wide as there were important intra-Community flows (representing approximately a third of total Community consumption) and no substantial price differences between Member States. Furthermore, the Commission noted that sandwich panels appeared to be more standardised products than profiles. The Commission took a similar approach in a 2001 decision.19

4.2.1.2.The Notifying Party's arguments

(30) The Notifying Party submits that the market for sandwich panels is EEA-wide for the following reasons: (i) there are no significant import duties or trade barriers, (ii) there are no significant variations in product requirements according to regions, (iii) transport costs are low relative to the value of the products, (iv) there are substantial trade flows within the EU, (v) average transport distance for the Parties' products is between [200-350] and [800-1200] km depending on the facility, (vi) there are no significant price differences across the EEA and (vii) no physical presence is required.

4.2.1.3.Commission's assessment

(31) Based on the feedback from market participants, the internal documents of the Parties, and the quantitative elements available, the relevant market for sandwich panels appears smaller than EEA-wide, with the exception of the relevant market for mineral wool panels. The reasons for this conclusion will be explained in this section.

Regional trade-flows

(32) The market investigation confirmed the existence of trade flows within the EEA. For instance, based on the Notifying Party's submission intra-EU imports amount to 30% of domestic sales in Belgium, 42% in the Netherlands, and 17% in the UK. However, these trade-flows appear mainly of a cross-border regional nature. For instance, Kingspan does not have a facility in Belgium, but serves the country mainly from France ([…]%) and the UK ([…]% - the remaining […]% is sourced from Ireland).

(33) The Parties' sales overall tend to be either in the area surrounding each production facility, or - in limited instances - in far-away locations outside the EEA on a project basis. For instance, the Parties have exports to locations such as the Middle-East and Australia.

(34) Meanwhile, Joris Ide's main facility is located in Belgium. This facility serves predominantly Belgium and the neighbouring area, as illustrated in Figure 3 below.

Figure 3: Extract from Joris Ide internal document on its market share around Belgium

[…]

Source: Internal document of Joris Ide entitled "Joris Ide Blueprint – Final document", 3 April 2013.

(35) While Joris Ide's facility is close to the UK, it stems from the above and from the Notifying Party's submission that its market share in the UK remains below 5%.

(36) Competitors state that their exports follow similar pattern. For instance, an Austrian player also sells in "Germany, Croatia, Netherlands and Switzerland", and has limited sales outside the EEA "for instance to Asia and New Zealand. But the local market is the most important one".20 Another competitor states that "Central and Eastern Europe (Bulgaria, Hungary, Moldavia, Serbia and Slovenia) can be reached from Romania. Benelux, Poland and Czech Republic can be reached from Germany and Southern France and Portugal can be reached from Spain."21

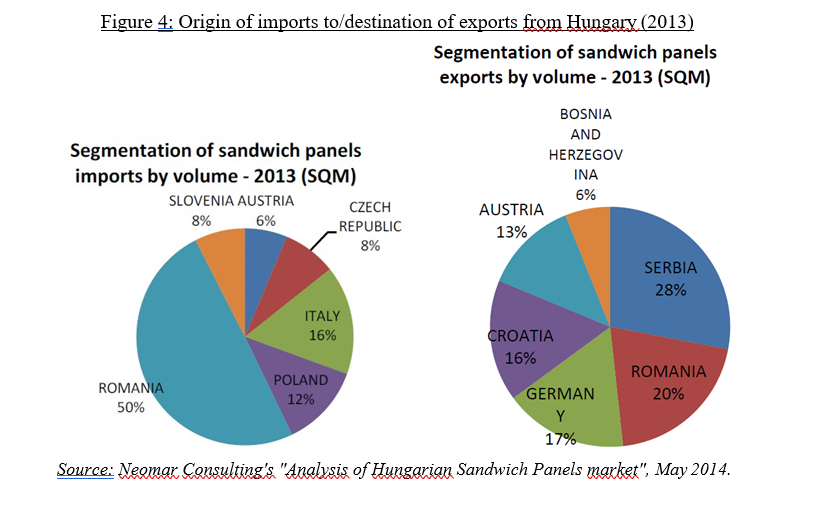

(37) In EEA countries, exports and imports tend to remain mainly within the same area, as illustrated by the industry report on Hungary in Figure 3.

(38) One notable exception is the sales of Southern European players into Northern Europe. Market players such as the Spanish company Huurre and Italian players for instance have some sales in Northern Europe. However, these sales remain limited in the three areas of interest in this case (see section 5.1). Furthermore, Italian companies are in fact setting up some production capacity in Germany despite a high overcapacity in Italy, in order to reach out to Northern Europe. This indicates that, despite the high level of spare capacity in Italy, competitors feel the need to set up production in an area to compete there.

(38) One notable exception is the sales of Southern European players into Northern Europe. Market players such as the Spanish company Huurre and Italian players for instance have some sales in Northern Europe. However, these sales remain limited in the three areas of interest in this case (see section 5.1). Furthermore, Italian companies are in fact setting up some production capacity in Germany despite a high overcapacity in Italy, in order to reach out to Northern Europe. This indicates that, despite the high level of spare capacity in Italy, competitors feel the need to set up production in an area to compete there.

Importance of transport distance

(39) Transport distance appears quite important in the industry, and transport costs limit the main commercial reach of each production site to its neighbouring area, which explains the trade flows observed in the previous section.

(40) First, a majority of customers state that they purchase sandwich panels either locally, in the country or (cross-border) regionally.22 Most customers are open to sourcing from a neighbouring country if the price is satisfactory.23 For customers, delivery time is key: it is in the top 3 criteria driving competition, together with price and quality.24 Customers also mention the importance of service level. The average transport distance for customers varies, but is overall between 100 and 600 km.25 As stated by a Belgian customer, "[Customer] cannot consider buying panels from Spain or Italy as transport costs are too high. Proximity is also an advantage because producers from Belgium are able to supply [customer] in a short delay, which is very important in this industry."26

(41) Similarly, competitors overall state that they sell their panels mainly regionally, in the same and neighbouring countries as the plant where they are manufacturing.27 Competitors largely look at competition locally. As stated by a competitor "Typically the competition comes from cross-border regions due to the transportation cost."28

(42) Competitors mention an average transport distance between 350 and 800 km that still allows to achieve acceptable margins. As stated by competitors, "The estimated commercial reach of a production site is in a 500-600km radius around the plant. It is important to be close to where the consumption is."29 "The distance is relevant factor for profitability"30, and "in this industry, being close to the market is a big advantage. Transport costs are expensive and margins are very low"31. They state that the maximum distance would be 1 000 or 1 300 km.32 This is in line with the Notifying Party's statement that […]. There is also a separate category of very long distance trades to outside the EU, linked to specific projects (for instance to Australia and the Middle East). On average, competitors estimate transport costs to be between 6 and 25% of the price.33 Within the averages provided, it is stated that some specialized products travel more (see paragraphs (54) to (58) on mineral wool panels below).

(43) Secondly, internal documents of the Parties also highlight the relevance of transport distance when looking at the competitive landscape. A strategy presentation of Joris Ide shows the competitive landscape for Belgium as encompassing capacity from north of France, the Netherlands and west of Germany.

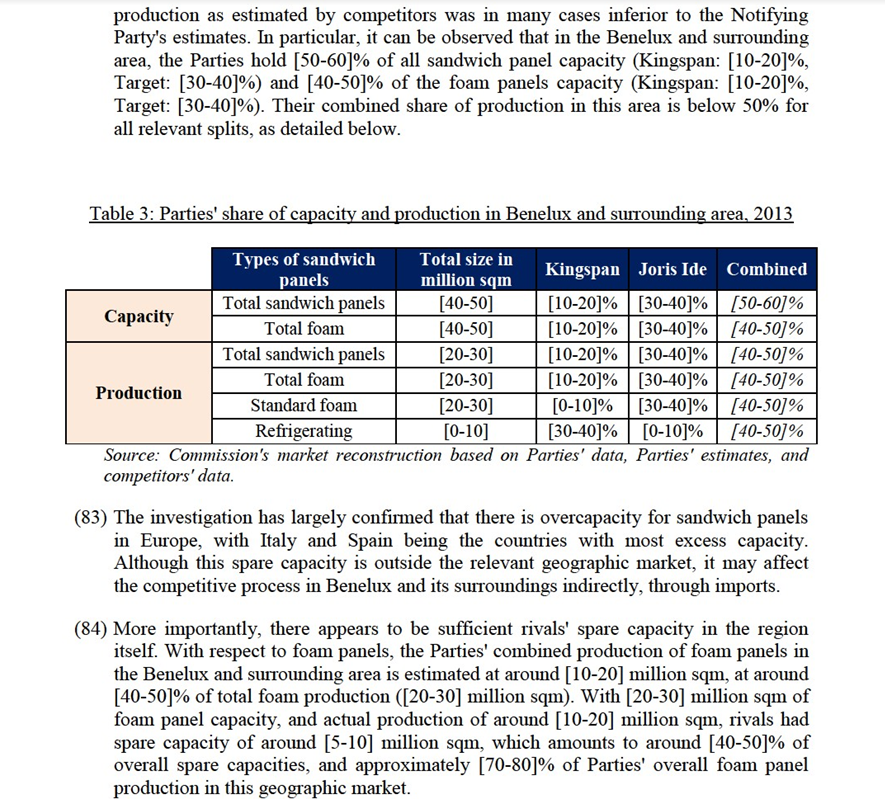

Figure 5: Extract from Joris Ide internal document on Belgium

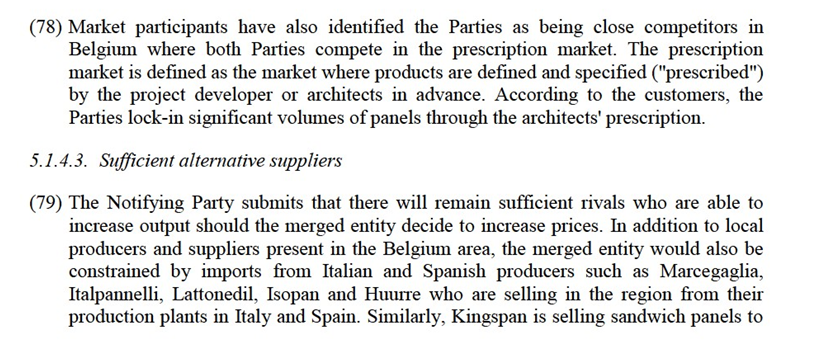

[…]

Source: Internal document of Joris Ide entitled "Joris Ide Blueprint – Final document ", 3 April 2013.

(44) In the same document, Joris Ide looks at competitors in a 400 km radius in relation to the setting up of its new factory in Germany. The fact that Joris Ide decided to set up a plant in the south of Germany also suggests that supplies from Belgian plants were considered inadequate to effectively compete in the area where the new plant will operate.

Figure 6: Extract from Joris Ide internal document on setting up in Germany

[…]

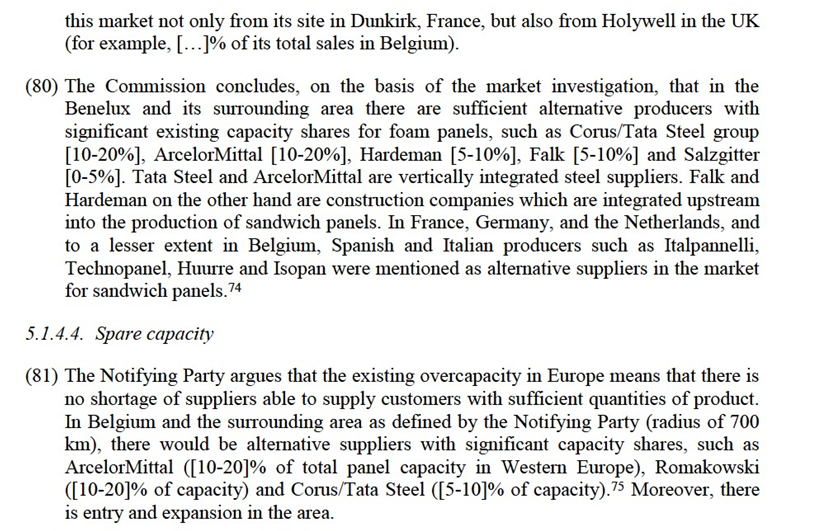

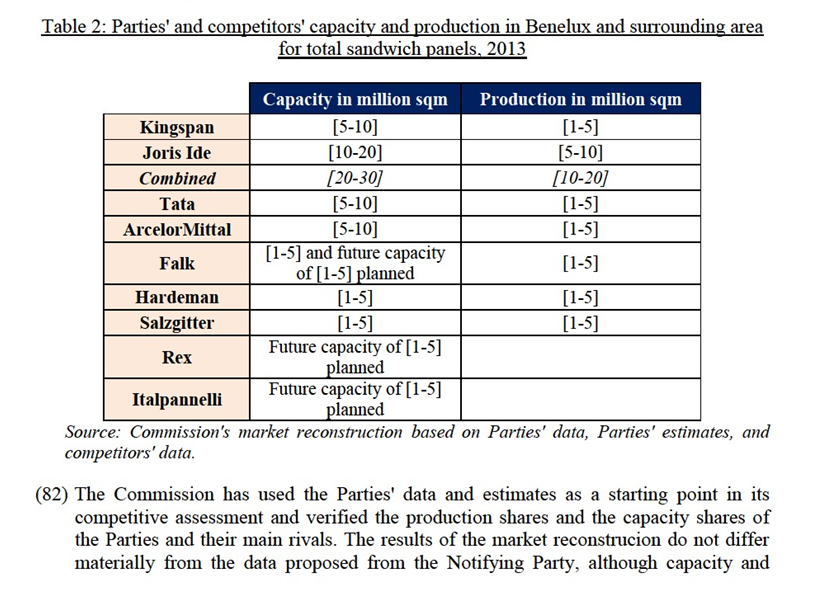

Source: Internal document of Joris Ide entitled "Joris Ide Blueprint – Final document", 3 April 2013.

(45) Publicly available documents from competitors indicate a similar perception of the logistics of supplying in a region.

(46) Furthermore, contrary to the Notifying Party's argument, operators perceive the need for sales presence, with at least sales office or agents needed to reach potential customers in a market. For instance a Spanish competitor indicates that "[i]t has commercial agents in France and Belgium and distributors in Portugal."35

(46) Furthermore, contrary to the Notifying Party's argument, operators perceive the need for sales presence, with at least sales office or agents needed to reach potential customers in a market. For instance a Spanish competitor indicates that "[i]t has commercial agents in France and Belgium and distributors in Portugal."35

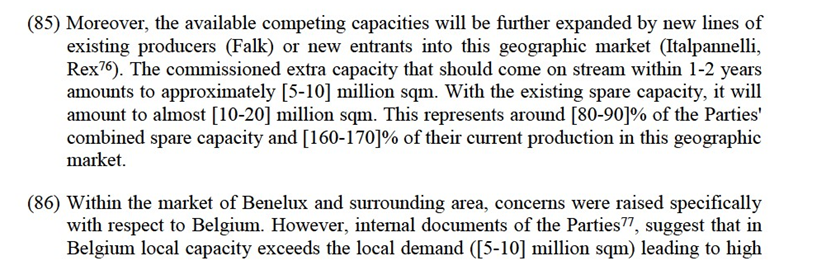

Further indications of a less-than-EEA-wide market: different requirements in some Member States, and different competitive landscape

(47) As explained above, transport cost is mentioned as a barrier by market participants, notably to get imports from Southern Europe to the Benelux region. But other factors limiting trade have also emerged in the course of the investigation.

(48) The UK and the Irish markets are seen as largely dominated by Kingspan, which accounts for [80-90]%36 of foam sandwich panels capacity in these two countries. "The Irish market is even more dominated by Kingspan. [Competitor] states that potential importers have not entered because of logistical costs. […] Without an industrial basis in the UK, it would be difficult for a mainland supplier to settle in the UK market."37 Barriers to enter the UK market are seen as very high.38

(49) The role of brands appears to play a role, and to vary by country or region. In this respect, Kingspan is one of the UK's leading business brands.39

(50) Then, it is perceived by customers that Italian and Spanish players offer lower quality, or different product specifications (for example, steel coating properties not adapted to climatic conditions in Western/Northern Europe)40. For competitors as well "[t]ypical South European producers are specialized in low quality, thin panels".4

(51) Moreover, some elements pointed to national specificities: both customers and competitors flagged certification/regulations and other national or local specificities.42 Competitors flag the different regulations (for instance standards for corrosion protection and fire), but also the differences in customer industry structure. "There are many national characteristics such as climate, regulation, customer industry structure etc."43 The certificates most frequently mentioned are the French "Avis technique" and the German "Zülassung". However, competitors state that such national regulations, on top of the European norm, are common in several EEA countries.44 In the UK the LPCB certification is also seen as a barrier ("This norm is effectively contributing into closing UK foam panel market from the competition"45). A competitor estimates the cost of LPCB certification at GBP 80 000-100 000 upfront, with further regular testing needed.46

Differences in prices and margins

(52) It stems from the investigation that prices differ to some extent by region within the EEA ("price level [differences of] up to 20%" between countries as stated by a competitor47). However it is noted that price differences are also linked to different characteristics in different countries. A large majority of competitors state that they set list prices for sandwich panels at cross-border region or at Member State level.48

(53) Margins of the Parties also differ depending on the country. For instance, Joris Ide had in 2014 a […] margin in a certain Member State which was several times higher than its margin in another Member State. Kingspan had margins of […]% in the UK and Ireland for sandwich panels, compared with […]% in Belgium.4950

Specificities of mineral wool sandwich panels

(54) Mineral wool panels can be distinguished from other sandwich panels for two related reasons: (i) they are more expensive, which in turn reduces the share of transport cost in the final price; and (ii) they are sold across Europe by a few players (in some cases specialized).

(55) A competitor states that "The manufacturing cost for wool panels is higher"51. Another notes that "The price of foam panels is lower than the price of mineral wool panels. Supplying mineral wool panels is more difficult as the product is thicker and heavier, but as prices are attractive transport costs represent a lower share of the cost. Wool panels therefore tend to travel more between countries."52

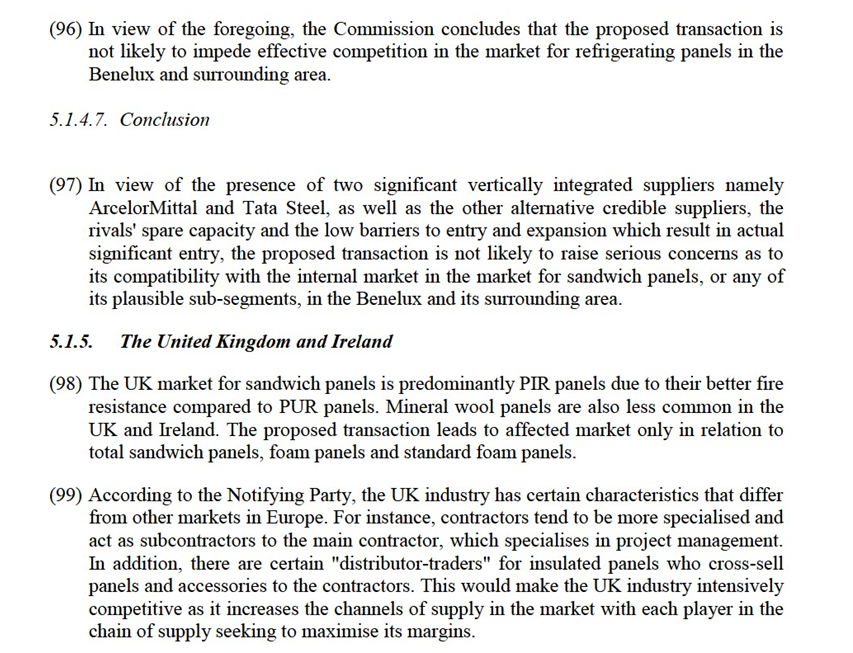

(56) Mineral wool products are usually more frequently used in the Nordic countries. But several players are active across Europe, such as Trimo,53 Ruukki, and Paroc. For instance, "[competitor]exports its production in every country of the European Economic Area with particular presence in the United Kingdom, France, Germany, Poland, Denmark, Netherlands, Czech Republic, Croatia and Slovenia."54A player active in mineral wool further states that it is competing with competitors world- wide.55

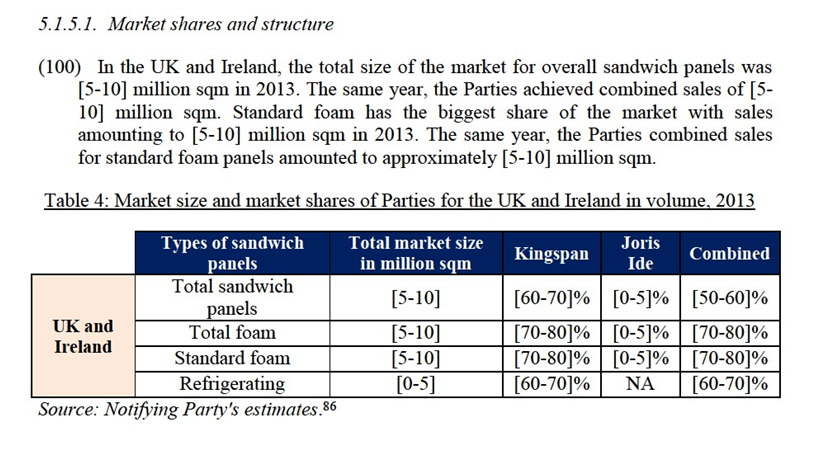

(57) Even in the UK, where the market is otherwise largely dominated by Kingspan and imports are limited, competitors without local production are also notable players for mineral wool sandwich panels.56

(58) Therefore, in relation to mineral wool sandwich panels specifically, the relevant market is considered to be EEA-wide in scope.

4.2.1.4.Conclusion

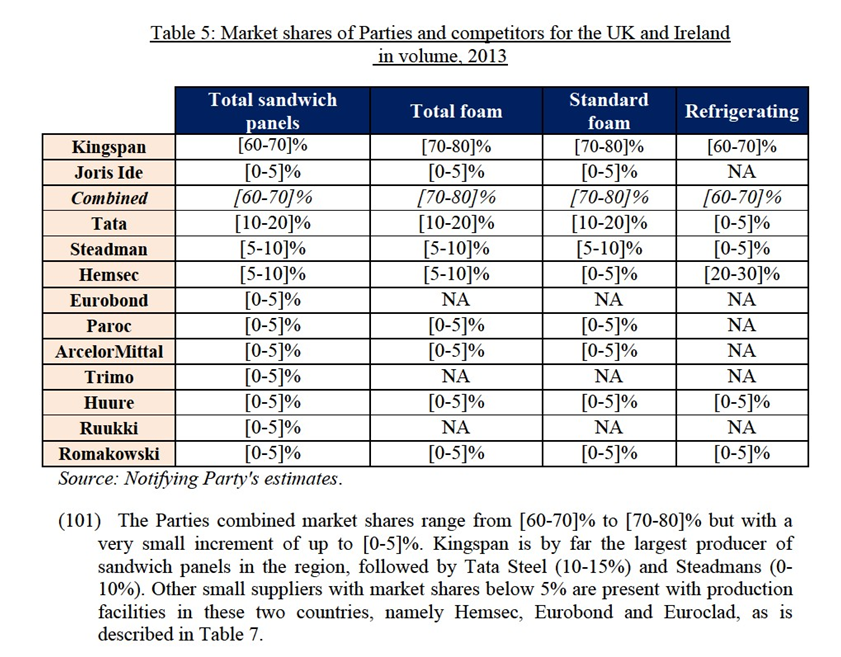

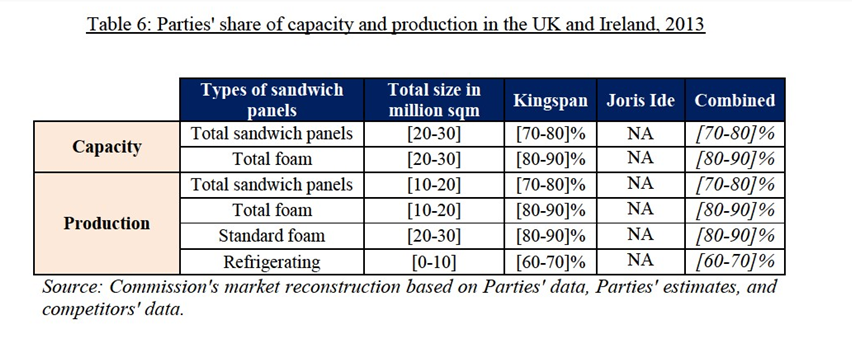

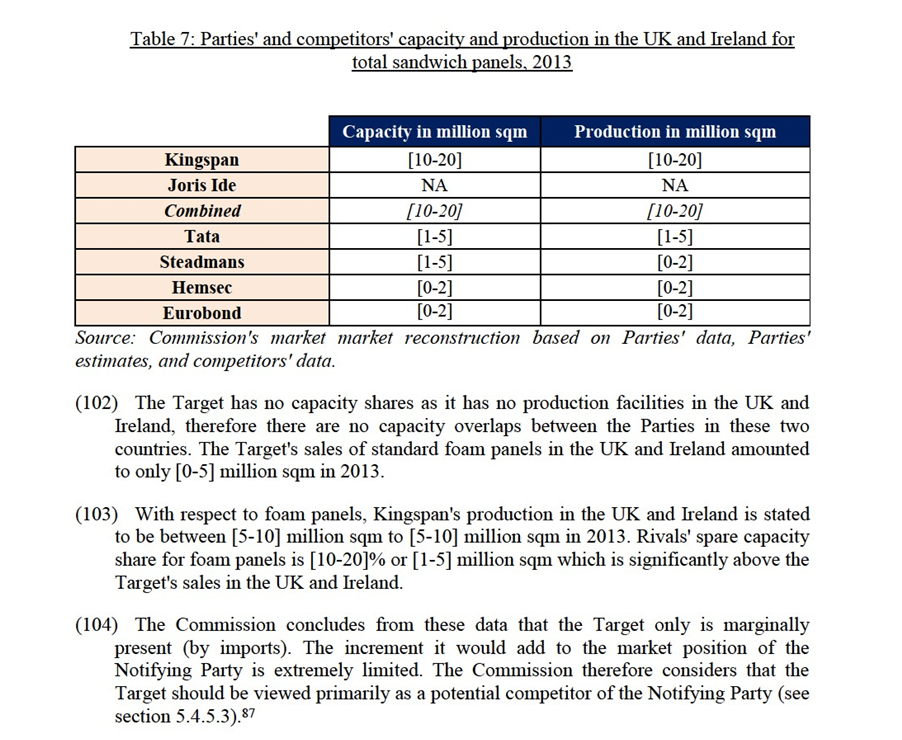

(59) In view of the above, with the exception of the market for mineral wool sandwich panels, the relevant market appears likely to be neither EEA-wide, nor national in scope. The relevant markets are very likely cross-border regions for all sandwich panels and foam sandwich panels (and sub-segments). However, as the transaction does not give rise to serious doubts as to its compatibility with the internal market neither at EEA-level nor at cross-border regional level (see section 5.1), the exact geographic market definition can be left open in this case.

(60) The competitive analysis of cross-border regions takes as its starting point the countries where the proposed transaction leads to the highest market shares for all sandwich panels and where concentration level is at the highest, namely Belgium, Hungary, Ireland and the United Kingdom. Based on this approach, three main regions are of interest in this case and will be analysed in section 5.157: i.Benelux and surrounding area, consisting of Belgium, the Netherlands, Luxembourg, north of France and west of Germany58; ii.The UK and Ireland; iii.Hungary and surrounding area, consisting of Hungary and parts of the neighbouring countries59.

(61) As explained above, for mineral wool sandwich panels, the relevant market is EEA- wide in scope. The Commission will not address this sub-segment separately any further in this decision, as no affected market arises at EEA-level (combined market share of the Parties of [10-20]% in 201360). The possible segmentation of total sandwich panels (that is to say, including both foam and mineral wool sandwich panels) will be assessed in section 5.1 below both at EEA and cross-regional level.

4.2.2.Construction sheets

4.2.2.1.Past decisional practice

(62) In previous decisions, the Commission has found that the relevant geographic markets for construction sheets were national in scope. Indeed, in those cases it was found that the importance of delivery times for small and medium sized construction projects, the need to provide technical assistance and after sale services to customers at construction sites, the low level of imports into these countries, price differences between Member States and, the existence of national standards and regulations61 supported the view that the relevant markets are national in scope.

(63) Nevertheless, these previous decisions did not differentiate between the Benelux countries, as transport costs and price differences are not significant and national standards are similar between Belgium, Luxembourg and the Netherlands.62 With regards to the Baltic countries it was also left open whether the markets are national or cross-border regional.63

4.2.2.2.The Notifying Party's arguments

(64) The Notifying Party argues that the Parties' average transport distance for construction sheets is [250-350] km. This average is lower than the average for sandwich panels as load values for construction sheets are much lower than sandwich panels. Consequently, it is less profitable to ship construction sheets as far as sandwich panels. The Notifying Party therefore concurs with the Commission's previous assessment of the geographic scope for construction sheets as national in scope.

4.2.2.3.Commission's assessment

(65) The Commission considers for the purpose of the assessment of this case that the relevant markets for the production and supply of construction sheets are national in scope.

5.COMPETITIVE ASSESSMENT

5.1.Sandwich panels

5.1.1.Introduction

(66) As explained in the Commission's Horizontal Merger Guidelines, where the market share - in a particular product and geographical market, as assessed in section 4 of this decision – of the undertakings concerned does not exceed 25%, the Commission can presume that the concentration is not liable to impede effective competition on that market.64 The Commission will apply that assumption in this case.

(67) Based on the approach and segmentations set out in sections 4.1 and 4.2, the transaction would lead to the following affected markets: i. all sandwich panels, the potential segment for foam sandwich panels, and the potential sub-segment for standard foam panels at EEA level (section 5.1.3), ii.all sandwich panels, the potential segment for foam sandwich panels, the potential sub-segment for standard foam panels, and the potential sub- segment for refrigerating foam panels in Benelux and surrounding area (section 5.1.4), iii. all sandwich panels, the potential segment for foam sandwich panels, and the potential sub-segment for standard foam panels65 in the United Kingdom and Ireland (section 5.1.5), iv. all sandwich panels, the potential segment for foam sandwich panels, and the potential sub-segment for standard foam panels66 in Hungary and surrounding area (section 5.1.6).

(68) In relation to the calculation of shares in sections 5.1.4 and 5.1.6, the Commission's Horizontal Guidelines67 state that "market shares and concentration levels provide useful first indications of the market structure and of the competitive importance of both the merging parties and their competitors." As in this case the plausible geographic market is cross-border regional, and the Parties collect sales data on a national level, it was not possible to break-down the data for those areas which do not encompass the entire territory of a country (for example, the west of Germany). For this reason, the assessment in sections 5.1.4 to 5.1.6 will in addition rely on the information concerning capacity and production gathered in the Commission's market reconstruction for the relevant areas.68

5.1.2.General arguments of the Notifying Party

(69) The Notifying Party submits that the proposed transaction does not raise competitive constraints for the following reasons: (i) competitors are not capacity constrained and can easily switch production between different types of panels, therefore being able to react quickly to changes in demand, (ii) there are several significant competitors able to constrain the merged entity post-transaction, (iii) imports act as a strong competitive constraint and the majority of key suppliers make their sale entirely through imports, and (iv) volume reductions have a substantial impact on profitability, meaning the Parties cannot afford to lose relatively small volumes in the event of a hypothetical price increase.

5.1.3.EEA

5.1.3.1.Market shares and structure

(70) According to the Notifying Party, at the EEA level, the proposed transaction leads to affected markets for all sandwich panels, including the potential segment for foam panels, and the potential sub-segment for standard foam panels.69

(71) Again, according to the Notifying Party, the total size of the overall sandwich panels market at EEA level was 140 million sqm in 2013. The same year, the Parties' sales amounted to approximately [20-30] million sqm for Kingspan and [5-10] million sqm for the Target. The Parties' combined market shares for all sandwich panels at EEA level in 2013 was approximately [20-30]% with an increment of [5-10]% from the Target. For foam sandwich panels, their market similarly reached [20-30]% with an increment of [5-10]% from the Target.

(72) The most important sub-segment in the overall sandwich panels is the one for standard foam panels with sales amounting to approximately [90-110] million sqm (70% of the overall market). At the EEA level, the Parties' combined market share for standard foam panels is [20-30]% with an increment of [5-10]% from the Target.70

5.1.3.2.Commission's assessment

(73) The Commission finds that the transaction is unlikely to have an anticompetitive impact on any of the plausible product markets at the EEA level for the following reasons: i.Limited market shares and a number of significant competitors. The Parties together hold [20-30]% of all sandwich panel sales, [20-30]% of foam sandwich panels, and [20-30]% of sales of standard foam sandwich panels in the EEA. There is a number of other significant competitors in the EEA which would continue to pose a competitive constraint on the Parties, notably ArcelorMittal and Isopan (around 10% each), as well as Tata Steel, Metecno, Marcegaglia, Italpannelli, Lattonedil (5-10% each). Smaller competitors include Romakowski, Brucha, Balex, Huurre and Ruukki (1-5% each); ii.Competitors have significant spare capacity for both mineral fibre and foam sandwich panels, estimated at above 30% of their overall capacities, and are thus capable of constraining the Parties’ conduct;71 iii. Entry of new operators (such as Falk and Rex) and expansion of established suppliers (Lattonedil, Italpannelli, Isopan)72 shows that entry is sufficiently easy and attractive and may pose additional competitive pressure on the Parties.

5.1.4.Benelux and surrounding area

(74) Both Parties have production facilities in the Benelux and surrounding area: the Target's production hubs in Zwevezele and Manhay (Belgium) and Kingspan's plants in Dunkirk (France) and Kreuztal (Germany). Kingspan also exports sandwich panels from its UK and Irish facilities into the Benelux and surrounding area.

5.1.4.1.Market shares and structure

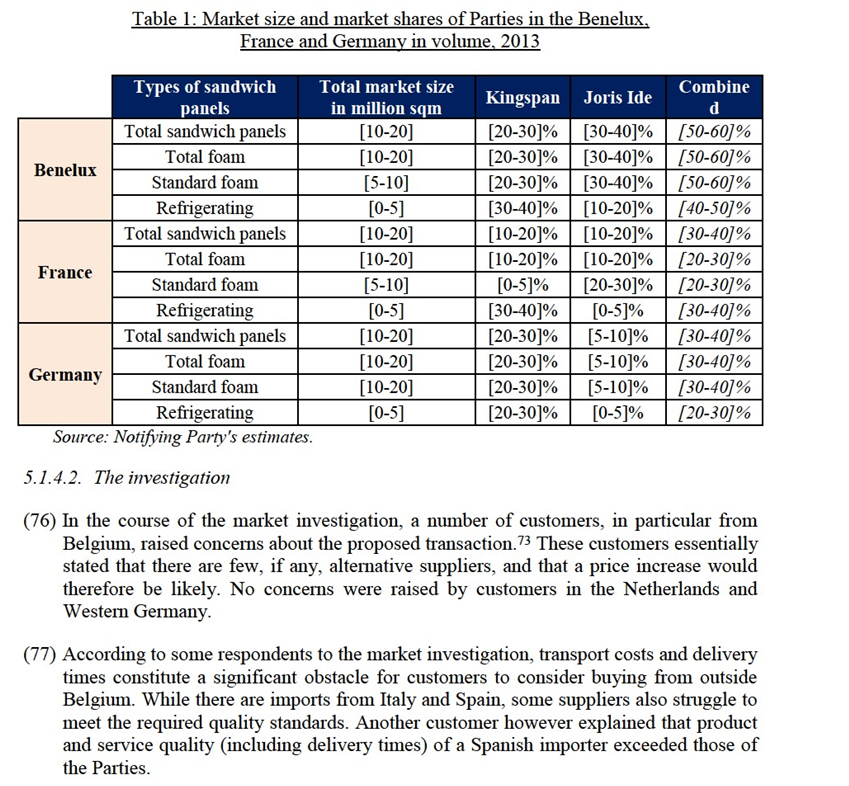

(75) The Notifying Party indicated that if the relevant geographic market for sandwich panels was limited to Belgium, the Parties' combined market shares for total sandwich panels would amount to approximately [50-70]%, with an increment of around [10- 30]% from Kingspan (supplies from France and the UK) in the overall sandwich panels market. However, as the assessment of the geographic market dimension showed that the market is at least cross-border regional in scope, such a market would thus not only include Belgium, but also the Netherlands, the western part of Germany, and the northern part of France. Although sales data relate to the entire territories of Germany and France and are not fully representative of the areas falling within the plausible geographic market of Benelux and the surrounding area, the Parties' combined market shares appear to be generally lower outside Belgium (France – [30-40]%, increment of [10-20]%, Germany – [30-40]%, increment of [5-10]%, the Netherlands – [30-50]%, increment of [10-30]%). Sales market shares of the Parties for the potential splits (total sandwich panels, total foam, refrigerating and standard foam) are listed below.

exports. The Commission therefore concludes that competitors have sufficient capacity in the area ([5-10] million sqm) to constrain the Parties' possible attempts to reduce output and raise prices in Belgium. This conclusion can be drawn even without taking into account the significant future production capacity in the market (an additional [5- 10] million sqm).

exports. The Commission therefore concludes that competitors have sufficient capacity in the area ([5-10] million sqm) to constrain the Parties' possible attempts to reduce output and raise prices in Belgium. This conclusion can be drawn even without taking into account the significant future production capacity in the market (an additional [5- 10] million sqm).

(87) The Commission concludes, on the basis of the market investigation, that (i) there is sufficient rivals' spare capacity in Belgium and the surrounding area and (ii) there is overcapacity for sandwich panels in Europe, with Italy and Spain being the countries with most excess capacity. Although this spare capacity is outside the relevant geographic market, it may affect the competitive process in Benelux and surrounding area indirectly, through imports.

5.1.4.5.Entry and expansion

(88) The Notifying Party submits that barriers to entry in the region are low, since the required investments are relatively low (approximately EUR 6 million to set up a panel facility or a production line) and the numbers of sales representatives needed to have an effective presence in the country is limited and varies between 1-5 people for smaller countries and 5-10 people for larger countries.78

(89) The Notifying Party also puts forward that, despite the overcapacity in Europe, suppliers continue to invest in new production facilities. A standard sandwich panel line with capacity of around 2 million sqm requires a capital investment of around EUR 5-6 million and operates on low fixed costs (a production line can be turned on and off according to the demand). Additionally, the market for sandwich panels is expected to grow as energy saving is becoming more critical in Europe and the production of sandwich panels requires less energy than concrete. This is another reason why suppliers continue to invest in new production facilities in Europe.

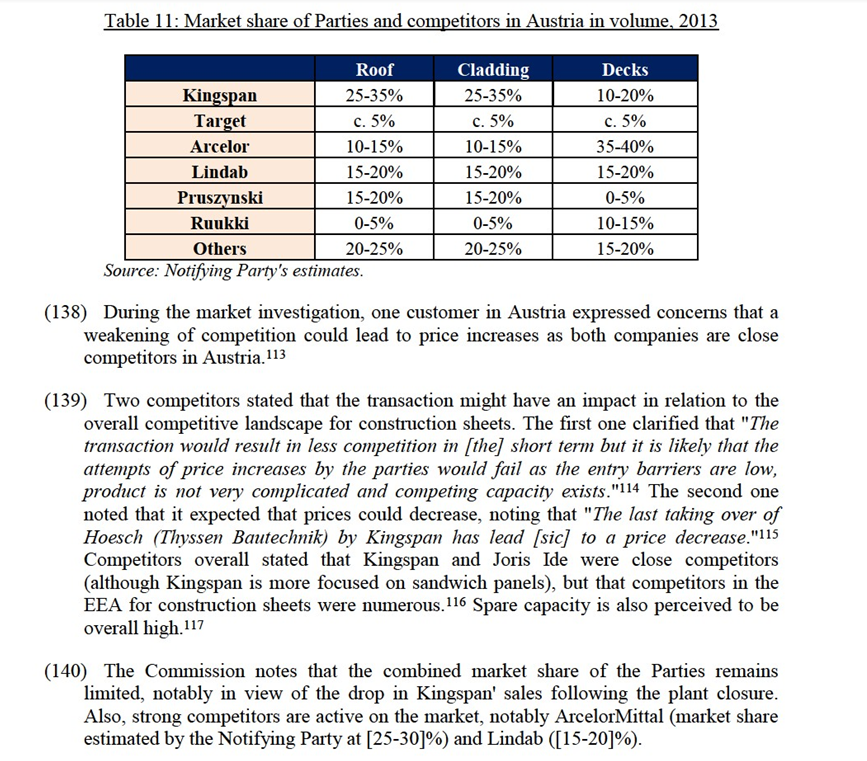

(90) The market investigation indicated that indeed setting up a new production line or facility in a country is relatively easy.79 Regarding some areas surrounding the Benelux, as analysed in section 4.2.1.3 above, there are certification requirements for sandwich panels in France and Germany that could possibly constitute a barrier to entry for some new producers with no previous sales in these countries.80 However, there are suppliers which export sandwich panels in Germany and France and already have the necessary certifications.81 Therefore if existing exporters wish to establish production lines in the area close to to the Benelux in these two countries, they could probably rely on existing certification which would likely be readily extended to products from the new facilities. At any rate, since it appears that the costs of certification were affordable even for importers, they a priori present even a smaller hurdle for operators which wish to set up local production plants and which therefore are likely to count on much higher volumes than are typically associated with exports.82 Moreover, according to the information provided by the Notifying Party, standards for sandwich panels are moving from national certification towards European norms. The European panel norm EN 14509 is in force now since several years. Since 1 January 2015, an Avis Technique in France is actually not anymore needed for standard foam panels (as opposed to refrigerating panels) as long as a supplier respects the European norm and has adequate quality assurance procedures in place. With respect to Belgium and the Netherlands, no special certifications for production and sale of sandwich panels are needed.

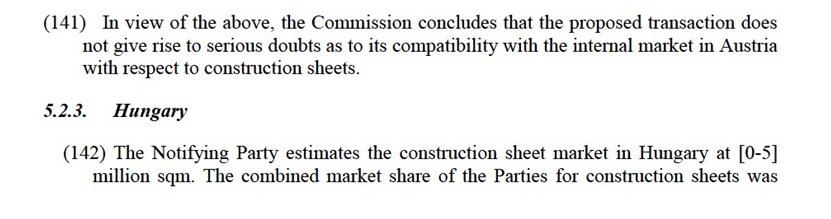

(91) Absence of barriers to entry and expansion is confirmed by recent events. Notably, the Italian supplier Italpannelli is building a new factory in Trier, Germany (i.e. in the cross-border region examined in this section). The plant intends to supply, amongst others, the Benelux region and is situated at the border with Luxembourg. It will add significant capacity of 4 million sqm per year and will become operational in 2016 and 2017. Similarly, Falk BV which recently entered the market, is also setting up an additional production line in the Netherlands which, according to the Notifying Party, will have a capacity of 2 million sqm and will be operational in the second quarter of 2016.

(92) The market investigation has also revealed other greenfield entries in the market for sandwich panels, such as Rex in Belgium, as well as planned increased presence of importers through distributors or sales agents in France and Belgium83. According to Tata Steel, five new production lines have been established in recent years in Europe, of which four in Germany and one in Belgium.84

5.1.4.6.Competitive analysis of the possible sub-segment of refrigerating panels

(93) With respect to the potential sub-segment for refrigerating panels, the Notifying Party submits that the combined market shares at a broader regional level would be below 40%. Even looking at national levels, the combined market shares would be below 40% and there will be sufficient alternative suppliers for refrigerating panels.

(94) The Commission's market reconstruction indicated that the merged entity would have a combined production share of [40-50]% with an increment of only [5-10]% from the Target in the Benelux and surrounding area. Looking at the national level, the Parties would have the highest combined market share in Belgium ([30-50]% with an increment of [10-30]% from the Target), the Netherlands ([30-50]% with an increment of [10-30]% from the Target) and France ([30-40]% with a very small increment of [0- 5]%). There would be no overlap in the potential sub-segment for refrigerating panels in Germany.

(95) Based on the data submitted by the Parties and the results of the market investigation, the Commission concludes that there are sufficient alternative suppliers in the region, namely ArcelorMittal and Tata Steel, who have production facilities in the region. Spanish supplier Huurre, a specialised cold-store producer with a spare capacity of [60- 70]%, also exercises a competitive constraint on the Parties, especially in Belgium and France where Huurre is mainly active in the cold-store segment.85 Other players such as Dagard and Romakowski could also act as constraints. As explained in section 4.1.1.3, there is also a degree of supply-side substitutability between standard foam panels and refrigerating panels.

greenfield entry in the UK and Ireland due to the LPC fire safety certification costs and the specificities of the UK channel structure.91

greenfield entry in the UK and Ireland due to the LPC fire safety certification costs and the specificities of the UK channel structure.91

(107) The majority of customers however did not express a concern. They explained that Kingspan and Joris Ide were complementary both in terms of product range and the prevailing distribution channels. Moreover, Joris Ide is seen only as a minor player in the UK and Ireland.

5.1.5.3.Potential competition by the Target

(108) With respect to the proposed transactions removing a potential competitor in the UK and Ireland, the Horizontal Merger Guidelines indicate that "for a merger with a potential competitor to have significant anti-competitive effects, two basic conditions must be fulfilled. First, the potential competitors must already exert a significant constraining influence or there must be a significant likelihood that it would grow into an effective competitive force. Evidence that a potential competitor has plans to enter a market in a significant way could help the Commission to reach such a conclusion. Second, there must not be a sufficient number of other potential competitors, which could maintain competitive pressure after the merger."92

(109) In relation to the first condition, as explained above, the Target has a very small market share in the UK and Ireland (up to [0-5]%) and while it has plans to increase its presence in the UK, these plans are modest. In an internal document concerning the UK market93, the Target identified three potential scenarios for improving its presence in the UK sandwich panel industry. These included […].94

(110) Additionally, the same internal document clearly shows that […]. Accordingly, the Target does not constitute an appreciable potential competitive constraint on Kingspan in the UK.

(111) With respect to the second condition, the Commission notes that, sufficient alternative suppliers will remain post-merger, in particular the vertical integrated supplier Tata Steel ([20-30]%), as well as Steadmans ([10-20]%) and the suppliers from mainland Europe ([5-10]%, see also the next paragraph)95. In addition, the Notifying Party submits that Kingspan's main competitor, Tata Steel, has local production facilities and is therefore in a much better position to expand than the Target is. Similarly, other competitors with production plants in the UK and who have market shares bigger than the Target, are also in a better position to expand.

(112) The Notifying Party claims that the merged entity would be constrained by a number of competitors located both in and outside the UK. The suppliers located in the UK are Tata Steel, Eurobond, Hemsec and Steadmans, but competition in the UK and Ireland comes also from suppliers located in mainland Europe, such as Ruukki, Paroc, ArcelorMittal and Huurre.

(113) The Commission agrees that indeed, Tata Steel is an important alternative supplier with [10-20%] of production in the UK and Ireland. Hemsec, Euroclad and Steadmans have also been identified as sandwich panel suppliers with domestic production lines in this market. Ruukki and ArcelorMittal are importers to this market, followed by suppliers from Italy and Spain that compete for big projects, albeit to a lesser extent 96. Eurobond on the other hand is only active in mineral wool panels97 where the Parties' activities do not overlap.

(114) In view of the foregoing, it can be concluded that the proposed transaction is unlikely to significantly impede effective competition in the UK through the elimination of a (primarily) potential competitor.

5.1.5.4.Different positioning of the Parties

(115) The Notifying Party submits that the proposed transaction does not remove a significant competitive constraint in the UK and Ireland in the market for sandwich panels. First, the Target has a very small market share of up to [0-5]% in the market for sandwich panels. Secondly, Kingspan targets the prescription market, whereas Target sells in the open specification market where products are supplied to meet open specifications defined by the owner of the building and supplied to the main contractor or the cladding contractor. It is estimated that Kingspan owns [10-20]% of the open specification market, Tata Steel owns [40-50]%, Steadmans [20-30]% and imports represent 20% of the market98. Finally, the large majority of the Target's sales (approximately […]%) in the UK are to caravan manufacturers, a segment in which Kingspan has never had any activities whatsoever; as a consequence, the remaining activities of the Target in sandwich panels in the UK are de minimis.

(116) Internal documents from the Parties show that, indeed, the Target sells predominantly to caravan builders in the open market (approximately […]% of its total sales of construction materials), as well as distribution traders (approximately […]%). Distribution traders resell Kingspan' panels on prescribed projects and other panels on the open specification market. This clearly confirms that the Target is mainly active in the open market, whereas Kingspan is mainly active in the prescription market.99 During the investigation, customers confirmed that Kingspan and the Target were complementary suppliers both in terms of product range and distribution channels.100

5.1.5.5.Entry and expansion

(117) According to the Notifying Party, entry and expansion by non-UK players in the UK sandwich panel industry is realistic and foreseeable. All that is required (if not producing in-country) is the minimum LPC certifications and detailed technical documentation according to UK norms/standards and a small but local technical sales organization (or agent) to provide technical assistance according to UK norms/standards. The LPC certification is a one-time cost (approximately EUR 50- 100 000 to certify sandwich panels) and is valid for five years.101

(118) According to some respondents to the market investigation, the main barriers to entry in the UK and Ireland market are the cost of the LPC certification and the logistics related to the UK channel structure.102 One competitor indicated that, however, LPC certification is not a prohibitive cost,103 while another competitor indicated that the higher the volumes sold, the easier it was to recoup certification costs.104

(119) The Commission concludes that any barriers to entry by EEA mainland players in the UK and Ireland market indeed appears to be not prohibitive. In particular, the estimated level of imports, which is around 17% in the UK as estimated by the Notifying Party,105 suggests that any certification and logistics costs are not as prohibitive as some of the respondents indicated. In particular, five non-UK producers are supplying the UK market from Belgium, Poland, Slovenia, Spain and Finland.

5.1.5.6.Conclusion

(120) In view of the above, the Commission concludes that the proposed transaction does not raise serious doubts as to its compatibility with the internal market in the UK and Ireland with respect to sandwich panels.

5.1.6.Hungary and surrounding area

5.1.6.1.Market shares and structure

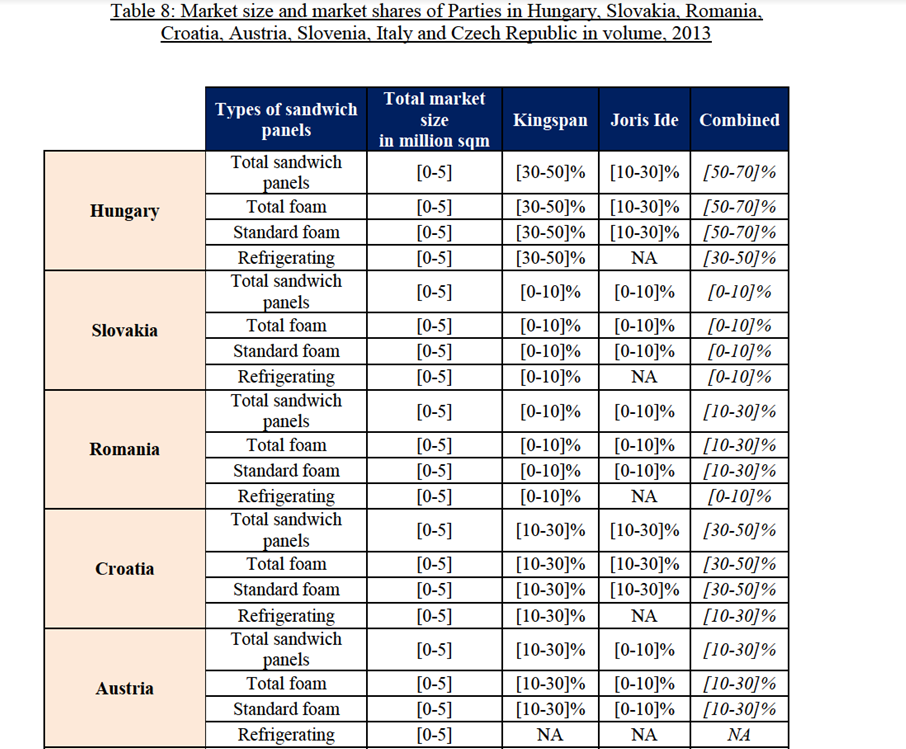

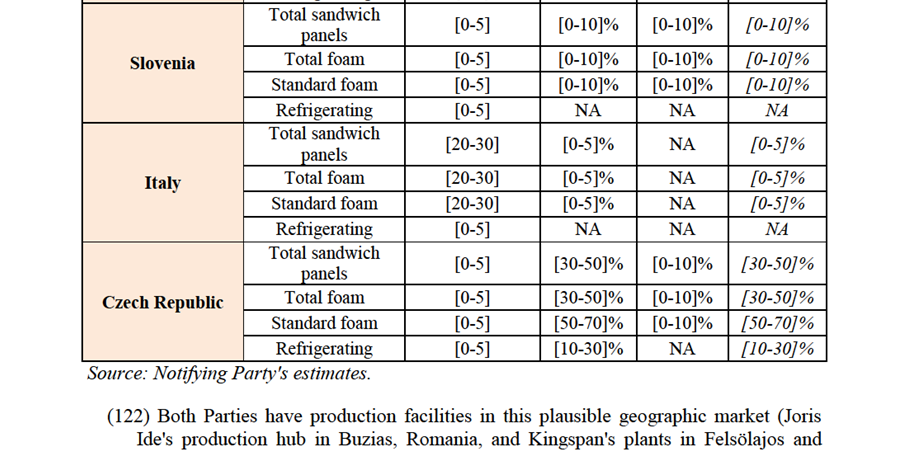

(121) The Notifying Party indicated that if the relevant geographic market for sandwich panels were Hungary, the Parties' combined market shares would amount to [50-70]% (increment of [10-30]% from the Target) regarding the market for all types of sandwich panels. However, as the assessment of the geographic market dimension showed that the market is at least cross-border regional in scope, such a market would thus not only include Hungary, but also parts of neighbouring countries (see section 4.2). Although sales data related to the entire territories of the neighbouring countries and are not fully representative of the areas falling within the plausible geographic market of Hungary and surrounding area, the Parties' combined market shares appear to be generally lower outside Hungary (Croatia – [30-50]%, increment of [10-30]% from the Target, Czech Republic – [30-50]%, increment of [0-10]% from the Target, Austria, Italy and Slovakia - no overlap, Romania – [10-30]%, increment of [0-10]% from Kingspan, Slovenia-[0-10]%, increment of [0-10]% from the Target).

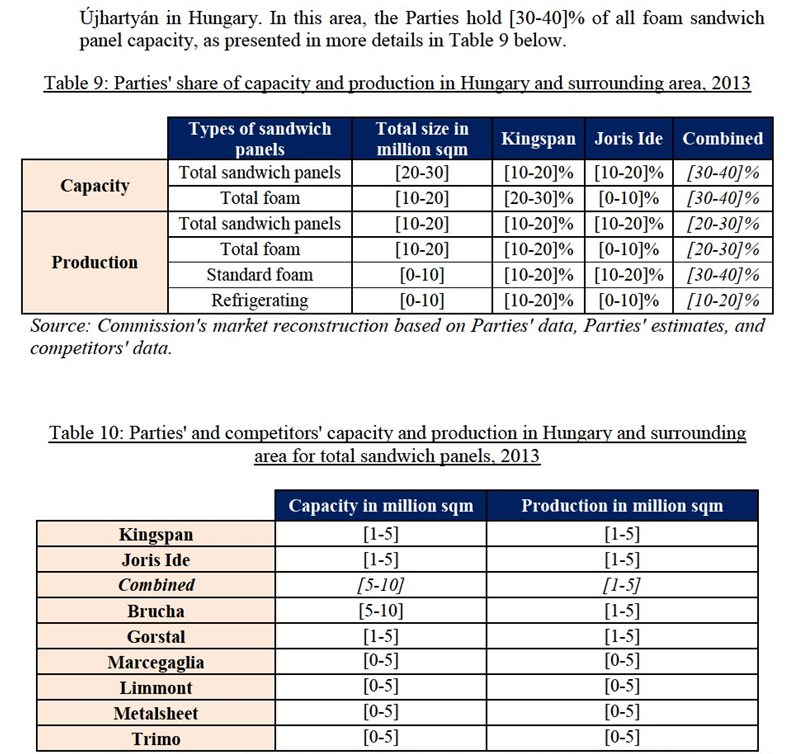

(125) According to the Commission's market reconstruction, in Hungary and the surrounding area, rivals' spare capacity amounts to [60-70]% in the foam panels which is significantly higher than the capacity share increment of [5-10%]% brought about by the Target. The proposed transaction brings about a volume increment of around [0-5] million sqm, which is lower than the rivals spare capacity of approximately [10-20] million sqm.

(126) The available spare capacity of the competitors to produce foam panels is double the combined production of the Parties (around [5-10] million sqm) in the region and sufficient to replace the Parties' combined sales (let alone the increment), should the merged entity raise prices.

5.1.6.4.Sufficient alternative suppliers

(127) The Notifying Party submits that there are enough alternative suppliers that could constrain the merged entity post-transaction, such as Isomec (30%) and Limmont (20%) in Croatia, Trimo and Balex in the Czech Republic (with 10% in each country), Ruukki, Isopan, ArcelorMittal in Hungary, ArcelorMittal, Elcom, Isopan in Slovakia, Italpannelli, Marcegaglia and Isopan in Slovenia to name a few.

(128) In addition, in Hungary, imports account for almost 60% of sales, coming mainly from Romania and Italy, with only two local suppliers in Hungary, namely Kingspan (Újhartyán and Felsölajos) and Metalsheet (Debrecen).

(129) The Commission notes that the presence of these suppliers in the Hungary and surrounding area was confirmed by market participants.108 In an external study109 submitted by the Parties to the Commission, the detailed analysis of imports (by volume) of sandwich panels in Hungary shows that, as the Notifying Party claims, 50% of imports come from Romania (main importers are Megaprofil, Ruukki, Plastsistem), 16% from Italy (main importers: Kingspan, ArcelorMittal, Ruukki), 12% from Poland (main importer: Kingspan), 11% from Slovenia (main importer: Trimo), 8% from the Czech Republic (main importer: Trimo), and the rest from Austria and Slovenia (Brucha, ArcelorMittal).

5.1.6.5.Entry and expansion

(130) The Notifying Party submits that transport costs of sandwich panels in Europe are low relative to the value of the products. More specifically, the Notifying Party estimates that transport costs represents less than 5-10% of all sales made within the EU. Therefore transport costs do not represent an insurmountable barrier to manufacturers switching supply between different countries within the EEA.

(131) Respondents to the Commission's questionnaires from the Hungary and surrounding area identified investment costs, sales representatives, delivery distances, overcapacity and established commercial relationships as the main barriers to entry.110

(132) The total market size for overall sandwich panels in Hungary was [0-5] million sqm in 2013. That same year, imports amounted to 1.6 million sqm,111 therefore [70- 90]% of the total sandwich panel market in Hungary is served by imports. Given the high percentage of imports into Hungary and the geographic span from which these imports come (Romania, Poland, Italy, Slovakia, Austria), the Commission concludes that expansion of existing suppliers (either through direct sales, distributors or sale agents) into this region seems feasible and delivery distances do not seem to represent a significant barrier to entry.

5.1.6.6.Conclusion

(133) In view of the above, the Commission concludes that the proposed transaction does not raise serious doubts as to its compatibility with the internal market in the Hungary and surrounding area with respect to sandwich panels.

5.1.7.Conclusion

(134) In view of the above, the Commission concludes that the proposed transaction does not raise serious doubts as to its compatibility with the internal market with respect to sandwich panels.

5.2.Construction sheets

5.2.1.Introduction

(135) As discussed in section 4.2.2, the Commission's assessment is based on national markets. There are only two countries where the transaction results in affected markets, namely Austria and Hungary.

5.2.2.Austria

(136) The Notifying Party estimates the construction sheet market in Austria at 2.5 million sqm. According to the Notifying Party, the combined market share of the Parties was [40-50]% in construction sheets in 2013, with a limited increment of [0-5]% from Joris Ide. This share dropped to [30-40]% in 2014 (Kingspan: [20-30]%, Joris Ide: [5-10]%) following closure by Kingspan of the Hoesch Austrian plant in the wake of its acquisition of Hoesch in 2012. The Notifying Party submits that these market shares are slightly lower by value.112

(137) By end-use, the Notifying Party submits that the combined market share of the Parties in any of the possible sub-markets would not reach more than 40%, as illustrated in Table 11 below.

6.CONCLUSION

(148) For the above reasons, the European Commission has decided not to oppose the notified operation and to declare it compatible with the internal market and with the EEA Agreement. This decision is adopted in application of Article 6(1)(b) of the Merger Regulation and Article 57 of the EEA Agreement.

1 OJ L 24, 29.1.2004, p. 1 ('the Merger Regulation'). With effect from 1 December 2009, the Treaty on the Functioning of the European Union ('TFEU') has introduced certain changes, such as the replacement of 'Community' by 'Union' and 'common market' by 'internal market'. The terminology of the TFEU will be used throughout this decision.

2 OJ L 1, 3.1.1994, p.3 ("the EEA Agreement").

3 Publication in the Official Journal of the European Union No C 57, 17.2.2015, p. 6.

4 Publicly available Kingspan document "2014 in a nutshell", 2015 (http://www kingspan.com/~/media/Files/K/Kingspan/documents/kingspan-in-a-nutshell-2015.pdf ).

5 […].

6 The Notifying Party mentioned […]. […] was also capable of reviewing the transaction.

7 Replies to question 14 – Questionnaire to competitors (Q1).

8 Case M.1329 - Usinor/Cockerill (1999), paragraph 15.

9 The Parties also produce insulated roof tiles. The Notifying Party argues that these products are a variety of roofing panels, profiled as tiles and produced using the same line as sandwich panels. This was confirmed by a customer (Minutes of a call with a customer of 20 February 2015).

10 Replies to question 5 - Questionnaire to competitors (Q1) and question 8 - Questionnaire to customers (Q2).

11 Replies to questions 6, 7 and 8 - Questionnaire to competitors (Q1) and questions 9, 10, 11 and 12 -

12 One competitor explained that substitution was normally not possible, as "mineral wool panels are taken for 95% because of the non combustible nature. Since foam panels do not have the same protection to fire characteristics, it would not be possible to change from mineral wall to foam [sic]." Replies to question 7.1 – Questionnaire to competitors (Q1).

13 Replies to questions 9, 10 and 11 - Questionnaire to competitors (Q1).

14 Replies to questions 12, 13, 14 and 18 - Questionnaire to competitors (Q1) and questions 13, 14, 15 and 16 - Questionnaire to customers (Q2).

15 Replies to questions 15, 16 and 17 - Questionnaire to competitors (Q1). For example, a producer stated that "You only have to clarify some construction details. From manufacturing point of view you would need only some adoptions [sic] but in fact this is not a problem..". Another producer commented: "It is more a question of giving construction answers/ideas/details to architects. The sales and marketing departments are more challenged and not the production."

16 See Minutes of calls with competitors of 5 February and 4 March 2015.

17 Case M.7155 - SSAB/Rautaruukki (2014), paragraphs 50-56.

18 Cases M.1329 - Usinor/Cockerill (1999), paragraphs 22-26 and M.1595 - British Steel/Hoogovens

(1999), paragraph 13.

19 Case M.2382 - Usinor /Arbed/Aceralia (2001), paragraphs 11-13.

20 Minutes of a call with a competitor of 5 March 2015.

21 Minutes of a call with a competitor of 4 February 2015.

22 Replies to question 18 – Questionnaire to customers (Q2).

23 Replies to questions 19.1 and 21 – Questionnaire to customers (Q2).

24 Replies to questions 22 and 28 – Questionnaire to customers (Q2). See also Minutes of a call with a competitor of 18 February 2015.

25 Replies to question 22 – Questionnaire to competitors (Q1).

26 Minutes of a call with a customer of 6 February 2015.

27 Replies to question 20 – Questionnaire to competitors (Q1).

28 Replies to question 24.1 – Questionnaire to competitors (Q1).

29 Minutes of a call with a competitor of 4 February 2015. See also Minutes of a call with a competitor of 18 February 2015.

30 Replies to question 24.1 – Questionnaire to competitors (Q1).

31 Minutes of a call with a competitor of 5 March 2015.

32 Minutes of a call with a competitor of 5 February 2015 and replies to question 22 – Questionnaire to competitors (Q1).

33 Replies to question 23 – Questionnaire to competitors (Q1).

34 http://www.ruukki.com/~/media/Files/Investors/Capital%20Market%20Days/Capital%20Market%20 Day%202006/CMD Hirviniemi 26092006.pdf

35 Minutes of a call with a competitor of 5 February 2015.

36 Commission's market reconstruction based on based on Parties' data, Parties' estimates, and competitors' data.

37 Minutes of a call with a competitor of 4 March 2015.

38 Minutes of a call with a competitor of 3 March 2015.

39 Kingspan press release "Kingspan is officially a Superbrand", 8 April 2013 (http://www kingspan.com/media/releases/pr2013/08-04-2013.asp).

40 See for instance Minutes of a call with a customer of 6 February 2015, Minutes of a call with a customer # of 26 February 2015, Minutes of a call with a customer of 20 February 2015, and replies to question 18.1 – Questionnaire to customers (Q2).

41 Replies to question 25.1 – Questionnaire to competitors (Q1). See also Minutes of a call with a competitor of 18 February 2015.

42 Replies to question 23.1 – Questionnaire to customers (Q2), and replies to question 25.1 – Questionnaire to competitors (Q1). See also for instance Minutes of a call with a competitor of 3 March 2015.

43 Replies to question 25.1 – Questionnaire to competitors (Q1).

44 Replies to questions 25.1 and 27 – Questionnaire to competitors (Q1).

45 Replies to question 27 – Questionnaire to competitors (Q1).

46 Minutes of a call with a competitor of 4 March 2015

47 Replies to question 25.1 – Questionnaire to competitors (Q1).

48 Replies to question 26 – Questionnaire to competitors (Q1).

49 Request for information 3, 20 February 2015

50 The Notifying Party submits, however, that the following elements prevent a comparison of margins between them and between countries: different methodologies between the Parties, a different product mix, and different distribution channels.

51 Replies to question 25.1 – Questionnaire to competitors (Q1).

52 Minutes of a call with a competitor of 4 March 2015.

53 Trimo is however experiencing financial difficulties and, according to market participants, Kingspan experessed an interest in acquiring Trimo. See Minutes of a call with a competitor of 4 February 2015 and Minutes of a call with a competitor of 4 March 2015.

54 Minutes of a call with a competitor of 4 February 2015. See also replies to question 21 – Questionnaire to competitors (Q1).

55 Replies to question 24 – Questionnaire to competitors (Q1).

56 Minutes of a call with a competitor of 4 March 2015.

57 While if looking at national level, France and Germany would be affected countries, Joris Ide does not have any production in France. While the overlap between the Parties’ facilities within the 400km radius does lead to Northern France forming part of an affected market, there is no overlap of the Parties' production in Southern France such as to lead to an overlap in a 400km radius around Kingspan’s plant in Perpignan. Joris Ide has recently opened a plant in Ansbach, Germany, but no affected market would arise in a Southern Germany region encompassing Ansbach and other facilities in a radius of 400 km. This is notably due to the fact that players such as Romakowski, Tata Steel (Fischer) and Arcelor have facilities in the area. Similar considerations apply mutatis mutandis to geographical regions consisting of (parts of) other Member States and their surroundings which are not further discussed in this decision but where the concentration might lead to affected markets. That is because, inter alia, i) the estimated combined market share of the Parties there appears to be lower than in any of the geographical areas investigated in-depth in this decision, and ii) there appear to be various competitors with non-negligible market shares active in each of those possible markets (the Notifying Party mentions at least two and often more such competitors with regard to each market).

58 For the purposes of the assessment in this case, the Commission will look at production facilities in a 400 km radius from Brussels, which covers the relevant parts of France (north) and Germany (west).

59 For the purposes of the assessment in this case, the Commission will look at production facilities in a 400 km radius from Budapest. In terms of capacity of competitors, this includes facilities in Austria, Croatia, Hungary, Poland (its south), Romania and Serbia.

60 And [10-20]% in 2014. See reply to Commission request for information RFI 7 of 4 March 2015. For the definition of horizontally or vertically affected markets, see Annex 1 point 6.3 of Commission Implementing Regulation 802/2004, as last amended by Commission Regulation 1269/2013.

61 Case M.2382 – Usinor /Arbed/Aceralia (2001), paragraphs 27-30, Case M.1329 – Usinor / Cockerill

(1999), paragraphs 24-26, and Case M.7155 SSAB/Rautaruukki (2014), paragraphs 116-124.

62 Case M.1595 - British Steel / Hoogovens (1999), paragraph 12.

63 Case M.7155 - SSAB/Rautaruukki (2014), paragraphs 116-124

64 Guidelines on the assessment of horizontal mergers under the Council Regulation on the control of concentrations between undertakings (OJ C31, 5.2.2004, p.5), paragraph 18.

65 There is no overlap between the Parties in the refrigerating panels in the UK and Ireland.

66 No affected market arises in refrigerating panels in Hungary and surrounding area.

67 Guidelines on the assessment of horizontal mergers under the Council Regulation on the control of concentrations between undertakings, paragraph 8, (OJ C31, 5.2.2004, p.5).

68 Commission's market reconstruction based on Parties' data, Parties' estimates, and competitors' data.

69 Regarding the potential sub-segment for refrigerating panels, the transaction would not give rise to an affected market (in the sense of merger control rules) at the EEA level.

70 There are no affected markets at EEA level for either refrigerating or mineral wool panels.

71 Replies to question 43.4 – Questionnaire to competitors (Q1).

72 Replies to question 38 – Questionnaire to competitors (Q1).

73 Replies to question 44 – Questionnaire to competitors (Q2).

74 Replies to question 28 – Questionnaire to competitors (Q1).

75 The partie’s own estimates.

76 Rex is planning to launch its production of sandwich panels in March 2015. This said, some market participants stated that Rex was currently in financial difficulties.

77 See for example, Target’s internal document « Joris Ide Blueprint », April 2013, Bain & Company.

78 See reply to Commission request for information RFI 4 of 26 February 2015

79 Replies to question 41 - Questionnaire to competitors (Q1).

80 Replies to question 27 - Questionnaire to competitors (Q1) and replies to question 33 - Questionnaire to customers (Q2).

81 Minutes of the call with competitor of 3 March 2013.

82 Minutes of a call with a competitor of 3 March 2015.

83 Minutes of a call with a competitor of 3 March 2015.

84 Replies to question 38 - Questionnaire to competitors (Q1).

85 Minutes of a call with a competitor of 3 March 2015.

86 Internal documents of Joris Ide estimate foam panels at 10.1 million sqm and mineral wool panels at 0.5 million sqm. See target internal document « UK Strategy Board 04/02/2014 », Slide 7. « Na » stands for « Not applicable ».

87 To the extend that the Target is an actual competitor of the Notifying Party, it can be noted that the facts explained in this section also do not lead to finding serious doubts from that perspective. For instance, the Target’s market share is small. Moreover, the customers have possibilities to switch supplies.

88 Replies to questions 43-45 – Questionnaire to customers (Q2).

89 Replies to questions 44-46 – Questionnaire to customers (Q1).

90 Replies to questions 43-45 – Questionnaire to customers (Q2).

91 Replies to question 38 - Questionnaire to customers (Q2).

92 Guidelines on the assessment of horizontal mergers under the Council Regulation on the control of concentrations between undertakings, paragraph 60.

93 Internal document of Joris Ide entitled "UK Strategy Board 04/02/2014".

94 Internal document of Joris Ide entitled "UK strategy Board 04/02/2015".

95 Market shares for PIR panels according to Target internal document "UK Strategy Board 04/02/2014", slide 8. In this scenario (PIR only), the combined market share of the Parties would be [60-70]% wity [0-5]% increment from the Target.

96 Minutes of a call with a competitor of 5 March 2015.

97 Minutes of a call with a competitor of 4 March 2015.

98 See for example Target internal document "UK Strategy Board 04/02/2014", slide 10.

99 See for example Target internal document "UK Strategy Board 04/02/2014", slide 5.

100 Replies to questions 43-45 - Questionnaire to customers (Q2).

101 Annual audit costs are estimated at around EUR 2 400 per year.

102 Replies to question 23 - Questionnaire to customers (Q2).

103 Minutes of a call with a competitor of 4 March 2015.

104 Minutes of a call with a competitor of 3 March 2015.

105 Internal documents of Joris Ide estimate imports in the UK at 5 to 10% for foam panels and 35 to 40% for mineral wool panels. See Target internal document "UK Strategy Board 04/02/2014", slide 7.

106 Replies to questions 43-44 - Questionnaire to customers (Q2).

107 The Notifying Party assumes an area of 700 km Road distance from Budapest. See submission on Hungary, 3 march 2015.

108 Replies to questions 26 and 27 – Questionnaire to Customers (Q2).

109 Neomar Study, "Analysis of Hungarian Sandwich Panels Market", slide 17.

110 Replies to question 38 – Questionnaire to Customers (Q2) and replies to question 37 – Questionnaire to Competitors (Q1)

111 Neomar Study, "Analysis of Hungarian Sandwich Panels Market", slide 17.

112 Reply to Commission requests for information RFI 2 of 17 February 2015 and RFI 7 of 4 March 2015.

113 Replies to questions 45.1 - Questionnaire to customers (Q2).

114 Replies to questions 46.1 - Questionnaire to competitors (Q1).

115 Replies to questions 46.1 - Questionnaire to competitors (Q1).

116 Replies to questions 42 and 46.1 - Questionnaire to competitors (Q1).

117 Replies to questions 43.4 - Questionnaire to competitors (Q1).

118 Reply to commission request for information RFI 2 of 17 February 2015 and RFI 7 of 4 March 2015.

119 Replies to questions 45.1 - Questionnaire to costumers (Q2).