Commission, May 23, 2018, No M.8831

EUROPEAN COMMISSION

Judgment

MONDI / POWERFLUTE

Subject: Case M.8831 – Mondi / Powerflute

Commission decision pursuant to Article 6(1)(b) of Council Regulation No 139/20041 and Article 57 of the Agreement on the European Economic Area2

Dear Sir or Madam,

(1) On 11 April 2018, the European Commission received notification of a proposed concentration pursuant to Article 4 of the Merger Regulation by which Mondi Finland Services Oy (belonging to the Mondi Group – "Mondi", Austria) acquires within the meaning of Article 3(1)(b) of the Merger Regulation sole control of the whole of Powerflute Group Holdings Oy ("Powerflute", Finland) by way of purchase of shares (the "Transaction").3 Mondi is designated hereafter as the "Notifying Party" and together with Powerflute as the "Parties".

(2) This Transaction was referred to the Commission from the Republic of Finland pursuant to a Commission decision on the basis of Article 22(3) of the Merger Regulation, of 14 March 2018.4

1.THE PARTIES

(3) Mondi is a vertically integrated global packaging and paper group. It is mainly active in the manufacturing of packaging paper, converted packaging products and uncoated fine paper. Mondi also produces films and laminates for consumer flexible packaging and converted consumer flexible packaging products, industrial bags, extrusion-coated and laminated protective materials, and siliconised release liner products (i.e. siliconised paper, films and non-wovens).

(4) Powerflute operates an integrated pulp and paper mill in Kuopio, Finland and is mainly active in the production of Nordic semi-chemical fluting ("NSCF"), a material used to manufacture corrugated packaging. It is also active in the procurement of wood via its subsidiary Harvestia Oy ("Harvestia"), a wood supply company based in Finland.

2. THE OPERATION

(5) Pursuant to a share purchase agreement of 22 December 2017, Mondi will acquire 100% of the total share capital of Powerflute, and will therefore solely control Powerflute post-Transaction.

3. EU DIMENSION AND THE COMMISSION’S JURISDICTION

(6) The undertakings concerned have a combined aggregate world-wide turnover of more than EUR 5 000 million (Mondi EUR 7 120 million; Powerflute EUR 183 million), however Powerflute does not have an aggregate EU-wide turnover in excess of EUR 250 million (Mondi EUR […] million; Powerflute EUR […] million). As a result, the Transaction does not have an EU dimension within the meaning of Article 1 of the Merger Regulation.

(7) On 6 February 2018, the Commission received a request to examine the concentration ("Referral Request") from the Republic of Finland under Article 22(1) of the Merger Regulation. The Referral Request was subsequently joined by the Kingdom of Spain. On 14 March 2018, the Commission adopted a decision pursuant to Article 22(3) of the Merger Regulation, accepting the Referral Request. On this basis, the Commission acquired jurisdiction to review the Transaction.

4. COMPETITIVE ASSESSMENT

4.1.Relevant markets

(8) The Transaction gives rise to one horizontally affected market were the market to be defined as virgin wood fibre fluting, which is a type of corrugated case materials ("CCM").

(9) Furthermore, one vertically affected relationship arises, as regards the Parties' activities in relation to virgin wood fibre fluting (upstream) and Mondi's activities in manufacture and supply of corrugated packaging (downstream).

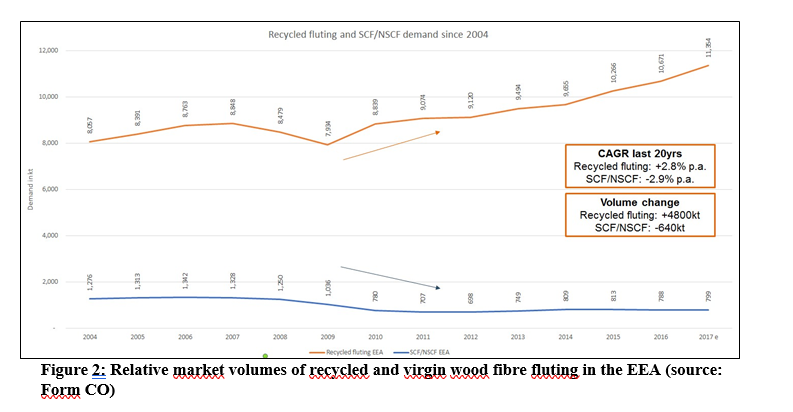

(10) The relevant markets will be further discussed below.

(11) For completeness, the Commission notes that the Transaction also results in a horizontal overlap in relation to the manufacture of wood pulp5, as well as a vertical relationship between Powerflute's activities in relation to the purchase and sale of wood (upstream) and Mondi's merchant activities in relation to wood pulp (downstream)6. However, as no affected markets arise therefrom, the Commission will not discuss these further in this decision.

(12) Finally, a technical vertical relationship could be argued to exist between Mondi's activities on the merchant market for thesupply of wood pulp (upstream) and the Parties' activities with regard to the production of virgin wood fibre fluting (downstream). However, given that Powerflute's NSCF production plant forms an integrated whole including also a pulp mill that feeds all of the production plant's needs, Powerflute does not buy wood pulp. As such, this technical vertical relationship cannot lead to input or customer foreclosure and will thus not be discussed further in this decision.

4.1.1.Corrugated Case Materials

(13) CCM refer to a portfolio of products which are the main inputs for the manufacturing of corrugated packaging. CCM includes both liners, forming the flat outer layers of corrugated packaging, and fluting, which is the rippled middle layer of corrugated packaging providing rigidity, bulkiness and strength. CCM are used to manufacture corrugated sheets, which are in turn converted into corrugated boxes. Mondi offers both liners and fluting, whereas Powerflute is only active as regards fluting.

Figure 1: CCM (source: Form CO)

(14) Both liners and fluting can be made from virgin wood fibres or from recycled fibres, as well as from a mix of the two. Liners produced from virgin wood fibres are called "kraftliners"; while "testliners" are made from recycled fibres.

(15) Fluting from virgin wood fibres can be (i) NSCF containing (almost) exclusively Nordic birch tree fibres7 and (ii) semi-chemical fluting ("SCF") containing a large proportion (around 70-80%) of virgin wood fibres, as well as recycled fibres (around 20-30%).

(16) Recycled fluting can be (i) high performance ("HP") recycled fluting, made out of 100% recycled fibres but the performance of which is improved by the addition of starch and other chemicals; and (ii) standard recycled fluting made out of 100% recycled fibres, also known as "Wellenstoff".

4.1.1.1.Product market definition

(17) In previous decisions, the Commission has considered a separate product market for CCM, with possible sub-segments for kraftliner (i.e. liner made from virgin wood fibres) and testliner (i.e. liner made from recycled fibres), but has ultimately left the market definition open.8 The Commission has not previously specifically assessed fluting.

The Notifying Party's view

(18) The Notifying Party submits that the relevant product market encompasses all CCM. It acknowledges that this market consists of a continuous spectrum of quality and performance options, but that this differentiation is not sufficient to support a sub-segmentation for the following reasons.

(19) First, while there is a differentiation between various grades in terms of absolute performance, both the grammage used9 as well as the liner/fluting combination can be adjusted so that various product solutions can essentially construct the same packaging. The decision as to which grade to use for a certain end- application depends on a combination of factors such as price, performance, corrugating equipment used by the customer, the customer's approach to box design, and overall customer preference.

(20) Second, there is substitutability between liners and fluting. Recycled liners and fluting are produced on the same production lines, and the same is true for kraftliners and virgin wood fibre fluting (though this is uncommon as a different type of pulp is needed). Liners and fluting can also be used interchangeably for certain applications and several producers offer products that can be used both as liner and fluting (so called "dual grade").

(21) Third, there is demand-side substitutability between recycled fluting and virgin wood fibre fluting, illustrated by the fact that within the context of a general increase in demand for corrugated packaging there is a decline in the use of virgin wood fibre fluting and a growth in the use of recycled fluting, suggesting that the former has been substituted by the latter.

(22) Fourth, although virgin wood fibre fluting is more expensive than recycled fluting on a per tonne basis, because a lower grammage will result in an equivalent strength to recycled fluting, there is a much greater degree of equivalence on a per square metre basis, so that when setting the SCF/NSCF prices the pricing of recycled fluting has to be taken into account as any relative change could lead to customers switching.

(23) Fifth, CCM suppliers typically do not know for which end-application their product will be used, and different types of fluting (i.e. NSCF/SCF/HP recycled fluting) can be used for exactly the same end-applications, with a potential exception for a small minority of demand, for packaging for fruits and vegetables for transport over a 2-3 week timeframe under humid conditions, for which customers may prefer SCF or NSCF. According to the Notifying Party, this substitutability at the level of the corrugated packaging necessarily translates in substitutability at the upstream level for CCM inputs.

(24) Subsidiarily, the Notifying Party submits that should the Commission segment the market according to the different types of grades, it should, if a distinction between SCF and HP recycled fluting is upheld, do the same between NSCF and SCF as the difference in quality between Mondi's SCF and Powerflute's NSCF is comparable to that between Mondi's SCF and HP recycled fluting.

(25) Lastly, the Notifying Party submits that it is in any case not necessary to reach a conclusion on the relevant product market as no concerns arise irrespective of the market definition withheld.

The Commission's assessment Liners vs fluting

(26) As regards demand-side substitutability, the majority of respondents to the market investigation indicated that they generally do not use liners instead of fluting, that substituting fluting by liners is not recommended and that this is only done in exceptional situations of emergency where no other solution is possible, and this only for applications that are technically not challenging.10 It appears that also in case of a price increase, the majority would not consider switching from fluting to liners.11 On dual grade products, most respondents to the market investigation indicated that they do not use this because of price reasons and as availability is limited.12

(27) As to supply-side substitutability, the market investigation confirmed that the production process of liners and fluting is similar, and that both can often be produced using the same machines.13 It was however also indicated that especially for liners and fluting made from virgin wood fibres, a manufacturer must decide whether it wants to produce liner or fluting already at an early stage of the production process. Indeed, for virgin wood fibre CCM, this decision already has to be made during the kraft process14 as the cooking of the chips is done by different machines depending on whether liner or fluting will be manufactured.15 Another market participant also indicated that the cost of manufacturing NSCF or SCF is much higher than for kraftliner.16

(28) In view of the above and for the purpose of this decision, the Commission considers that liners and fluting form part of distinct product markets. As Powerflute is not active as regards the manufacture and sale of liners, this market will not be further discussed in the competitive assessment below.

Different types of fluting

(29) From a demand-side point of view, when it comes to fluting from virgin wood fibres and recycled fluting respectively, the market investigation showed that whereas it is technically possible to substitute recycled fluting with virgin wood fibre fluting, this is not an economically viable solution.17

(30) Furthermore, both competitors and customers indicated that virgin wood fibre fluting can in any case not be replaced by standard recycled fluting for a large part of the end applications for which virgin wood fibre fluting is used.18

(31) When it comes to the substitutability of HP recycled fluting and virgin wood fibre fluting, the picture is more varied. A few respondents to the market investigation indicated that the difference in performance impedes such substitution, and that this is as such only done in exceptional situations.19 Another respondent indicated that this is not evident as such switching often requires CCM customers to redesign their entire product.20 Yet another respondent indicated that for certain less demanding end-applications HP recycled fluting can substitute SCF, but that NSCF is in any case not to be substituted by HP recycled fluting.21 A competitor also explained that the difference, also in terms of prices, between HP recycled fluting and virgin wood fibre fluting is larger than the difference between the various grades of virgin wood fibre flutings.22

(32) However, despite these statements, the majority of market respondents suggested that HP recycled fluting can be a substitute for virgin wood fibre fluting (both SCF and NSCF), at least for certain end-applications.23 For example, while for transport of fruit or vegetables over a 2-3 week timeframe neither HP recycled fluting nor SCF appears to suffice, it seems that HP recycled fluting can just as well as SCF be used for instance for some short distance fruit and vegetable transportation, or for long-distance transportation of non-food products.24 Furthermore, 63% of respondents indicated that they have switched from SCF to HP recycled fluting in the past for the same end-application, and 31% of respondents indicated that they have in the past switched from NSCF to HP recycled fluting, for the same end-application.25

(33) As regards the demand-substitutability of different types of virgin wood fibre fluting specifically (i.e. NSCF and SCF), the results of the market investigation also appear to be not completely conclusive. Some respondents to the market investigation have indicated that SCF does not deliver an equal performance as NSCF due to the difference in fibre length and the inclusion of recycled material in SCF, such that generally a split is made between Nordic quality and Continental European quality fluting.26 Other respondents indicated however that SCF and NSCF are to a large extent interchangeable.27 Yet other respondents indicated that SCF is not qualitatively the same as NSCF, but both products belong to the same cluster of products.28

(34) The Commission understands that the substitutability of SCF and NSCF largely depends on the intended end-application. Both customers and competitors confirmed that for many end-applications, NSCF and SCF can be used interchangeably.29 It appears however that there are certain end-applications for which NSCF cannot be replaced by SCF (or by any other grade for that matter). Respondents to the market investigation indicated that next to regulatory reasons30, especially in case of long transport in the course of which the product is exposed to extreme conditions in terms of temperature or humidity, as is the case for long-distance transport of certain fruits and vegetables, it is necessary to use NSCF.31 A market respondent explained in this context that at least 60% of all instances in which NSCF is used also require the usage of NSCF, the other 40% concerns less demanding applications where NSCF could be substituted with other SCF products.32

(35) When it comes to the different types of recycled fluting in particular, it was explained that there is no specific customer base for the various types of recycled fluting; customers generally purchase different grades.33 The majority of respondents to the market investigation indicated that switching from HP recycled fluting to standard recycled fluting is technically possible for certain end- applications and if the grammage is increased. However, the majority also indicated that they had not switched between standard recycled fluting and HP recycled fluting in the past for the same end-application.34

(36) As regards the supply-side, the market investigation showed that when it comes to fluting from virgin wood fibres and recycled fluting – including HP recycled fluting – respectively, the production process is largely different. Not only is the raw material used different35; the process is also not done using the same production lines. Respondents further explained that for virgin wood fibre products a pulp mill is needed, the setting-up cost of which is very high. For these reasons, it is very difficult to switch production from one to the other.36

(37) When it comes to the various types of virgin wood fibre fluting and recycled fluting, the market investigation firstly confirmed the differences in composition, whereby NSCF uses virtually 100% virgin wood fibres from birch wood, SCF usually is a blend of virgin material and recycled waste paper and recycled fluting is completely made out of waste material with HP recycled fluting containing certain chemical additives in order to make it stronger and more moisture resistant.37

(38) As regards the different types of virgin wood fibre fluting specifically, it appears from the market investigation that while the length of the fibres used for respectively NSCF and SCF is different, the technical differences in relation to the production process of NSCF on the one hand and SCF on the other are minor.38 The Commission understands however that suppliers of virgin wood fibre fluting typically produce either NSCF or SCF, but not both.

(39) With regard to the different types of recycled fluting, the majority of market respondents indicated that it is easy to switch between different grades of recycled fluting using the same production line and without needing significant investments. The difference between the various types lies in the type of waste material used and the (amount of) chemical additives added.39 Another respondent that produces recycled fluting however suggested that so far, it has not been able to produce HP recycled fluting, most likely due a shortcoming in its technology.40

(40) In light of the above, for the purpose of this decision, the Commission considers that whereas overall there is limited substitutability between virgin wood fibre fluting and standard recycled fluting, HP recycled fluting can be a substitute for virgin wood fibre fluting from the demand-side point of view, at least for certain end-applications. The various grades of virgin wood fibre fluting in turn appear to be technical substitutes, except for certain more demanding end-applications for which only NSCF can be used.

(41) Also, within each main type of fluting various grades (white/brown, coated/uncoated) and grammages can be used to (partly) compensate differences in performance; there are hundreds of products available. On top of that, various designs of corrugated sheets exist that are similar in terms of performance.41 As such, the end-product is described as "a multi-layer product, whose performance is a result of all constituents of its structure and converting process variables applied throughout its manufacturing and supply phases".42

(42) Hence, while it seems that any substitutability at the downstream level, of the manufacture and sale of corrugated packaging, does not necessarily follow from substitutability at the upstream level for CCM inputs, there appears to exist a sliding scale of substitutability between the different fluting products, whereby substitutability largely depends on the intended end-application. As such, in case of a shortage of supply of a certain grade of fluting, the grade used could be reduced for those end-applications for which switching to a lower grade is possible.43 In this context, it also should be noted that at least for some of the end- applications for which switching to HP recycled fluting is not possible so that this does not exert a competitive constraint, SCF does not compete with NSCF either, and for some end-applications for which SCF and NSCF compete, HP recycled fluting forms a competitive constraint as well.

(43) In any event, for the purpose of this decision, the exact scope of the product market definition can be left open, as the Transaction does not give rise to serious doubts irrespective of the exact market definition upheld.

4.1.1.2.Geographic market definition

(44) In previous cases, the Commission has considered the market for the manufacture and supply of CCM as well as its possible sub-segments to be at least EEA-wide in scope.44

(45) The Notifying Party argues that this market is in fact global in scope, because both Parties make considerable shipments from the EEA to customers based outside of the EEA.45

(46) The replies to the market investigation (as well as the Parties' own sales data) show that customers do not tend to consider the distance between their production site and the manufacturing plant of their supplier to be of particular importance, at least for virgin wood fibre CCM products. As transport costs form a bigger proportion of the total costs for recycled CCM than for virgin wood fibre CCM and the density of manufacturing plants for recycled CCM is higher (there are many more plants producing recycled CCM in the EEA than virgin wood fibre CCM), distance however appears to play a larger role when it comes to recycled CCM.46

(47) However, whereas the market investigation confirmed that CCM products are exported outside of the EEA, it also showed that generally CCM products cannot economically be sourced from outside of the EEA, that the performance level of virgin wood fibre CCM products sourced from outside of the EEA tends to be lower than that of the corresponding products manufactured at EEA level, and that customers overall have a preference for products manufactured in the EEA.47 This finding is confirmed by the Notifying Party's statement that "imports into the EEA are relatively low i.e. circa 5%".48

(48) In any case, for the purpose of this decision, it can be left open whether the market is EEA-wide or global since the Transaction does not give rise to serious doubts under either alternative geographic market definition.

4.1.2.Corrugated packaging

(49) CCM is converted into corrugated sheet in a corrugator by gluing the fluting and the inside and outside liners together. Afterwards, the corrugated sheet can be further developed into corrugated cases by printing, slotting and/or die-cutting, folding and gluing and/or stitching the corrugated sheet.

4.1.2.1. Product market definition

The Notifying Party's view

(50) The Notifying Party does not contest the Commission's decisional practice and submits that it is not necessary to reach a definite conclusion with regard to the product market definition as no concerns arise irrespective of the exact market definition taken.49

The Commission's assessment

(51) The Commission previously considered separate relevant product markets for corrugated sheets on the one hand, and corrugated cases on the other hand.50 Furthermore, the Commission has previously considered that the market for corrugated sheets can be further sub-segmented into conventional and heavy duty sheets.51 Similarly, corrugated cases were further sub-segmented into conventional, heavy duty and litho-laminated corrugated cases.52

(52) The market investigation conducted by the Commission in the present case has not brought to light any indication that would contradict these earlier findings. In any event however, for the purpose of this decision the exact scope of the product market definition can be left open, as the Transaction does not give rise to serious doubts as to its compatibility with the internal market irrespective of the exact market definition upheld.

4.1.2.2. Geographic market definition

The Notifying Party's view

(53) The Notifying Party does not contest the Commission's decisional practice and submits that it is not necessary to reach a definite conclusion with regard to the geographic market definition either, as no concerns arise irrespective of the exact market definition taken.53

The Commission's assessment

(54) The Commission has previously considered the relevant geographic market to be national or regional in scope with a radius of 200-400 km around the relevant production site for both corrugated sheets54 and cases.55

(55) The market investigation in the present case indicated that the delivery distances of corrugated packaging are indeed shorter than those of the CCM products because of the bulkiness of such packaging, and that the transport cost is an important factor in the overall cost structure.56 Competitors and customers alike stated that the distance between the corrugator plant and the customer's plant is important.57 Indeed the majority of corrugated packaging is sourced/supplied within the same country, with some cross-border trading in neighbouring countries.58

(56) In any event, for the purpose of this decision, the exact scope of the geographic market definition can be left open, as the Transaction does not give rise to serious doubts as to its compatibility with the internal market irrespective of the exact market definition upheld.

4.2.Competitive assessment

4.2.1. Horizontal non-coordinated effects – fluting

4.2.1.1.Market structure

(57) The Parties' and their competitors' market penetration differs greatly based on the exact market definition taken. The overlaps of the Parties' activities with regard to fluting can be summarised as follows.

(66) Fourth, the Notifying Party argues that the Parties are not close competitors as Powerflute produces NSCF, while Mondi produces SCF and standard recycled fluting.64

(67) Lastly, the Notifying Party argues that the Parties' activities are complementary from a geographic point of view; Mondi's position in Central and Eastern Europe complements the presence of Powerflute in the Nordics.65

4.2.1.3.The Commission's assessment

(68) The Commission takes note of the fact that on an EEA-wide virgin wood fibre fluting market encompassing both NSCF and SCF, the Transaction would lead to the reduction of the number of suppliers from 4 to 3. The remaining approximately [60-70]% of the market is accounted for by two large competitors– BillerudKorsnäs and Stora Enso -, as well as a smaller Romanian supplier – Combinatul de Celuloza si Hartie – and minor imports.

(69) However, the Commission considers that other factors than structural elements also have to be taken into account in order to properly assess the competitive landscape of the potential virgin wood fibre fluting market.

Competitive interaction of the different fluting products

(70) As already discussed in section 4.1.1.1., the market investigation indicated that there is a sliding scale of substitutability between the different fluting products. In this regard the competitive interaction of specific fluting products depends mainly on the end-application they are destined for, i.e. the exact end-use of the corrugated packaging for which they are supplied.

(71) On the one hand, the market investigation showed that there are certain end- applications for which the use of NSCF is technically necessary, and for which therefore no substitution is possible.66

(72) Market participants pointed out67 several factors – such as extreme humid conditions, direct food contact, fatty food contact, exposure to changes in temperature, heavy products, long duration of transport, etc. - which lead to the necessity of using NSCF as fluting.

(73) Furthermore, the use of NSCF can be also required by law. In Italy for example,68 packaging coming into direct contact with i.a. food must consist purely of virgin raw materials, and must thus necessarily be NSCF (the most quoted example being pizza boxes).69 Similar regulation applies for corrugated packaging used by the UK Ministry of Defence.70

(74) In particular, the market investigation identified three main areas where NSCF cannot be substituted and therefore the Transaction would not bring about any changes in the competitive landscape, given that Mondi does not produce NSCF.

These are i. applications for which the use of NSCF is required by law; ii. fruit and vegetable packaging, in particular for long-distance transportation in humid conditions;71 and iii.heavy-duty corrugated packaging products where corrugated packaging replaces wooden crates.72

(75) This is also reflected in the sales of Powerflute. Although suppliers are not aware of the exact breakdown of their fluting sales by end-application as this is often not indicated by their customers, based on the location of the customers' corrugator plants and market intelligence Powerflute estimates that […]% of its sales are for fruit and vegetable transportation, the second most-common end-use being heavy- duty packaging.73 It is, however, not possible for Powerflute to estimate what proportion of its sales goes towards packaging destined for fruit and vegetable long-distance transportation.

(76) Given the lack of transparency with regard to end-applications, it is difficult to determine exactly the proportion of the total EEA volume of NSCF for which no substitution exists. However, the market investigation suggests that due to its higher price, NSCF is mainly used for applications that require the highest quality fluting for technical or legal reasons. A customer for example estimates that "at least 60% of the time when NSCF is used, this is absolutely necessary."74

(77) On the other hand, however, for the end-applications for which NSCF can be substituted, and therefore the Parties' products do compete with each other, the competitive constraint of HP recycled fluting has to be taken into consideration.

(78) Although some market participants indicated that no demand-side substitutability exists between virgin wood fibre fluting and recycled fluting,75 or that switching between these two would be considered only in extreme situations,76 the overall market investigation results showed that HP recycled fluting is in competition with virgin wood fibre fluting for certain end-applications (see also section 4.1.1.1.).

(79) Indeed, 31% of the respondents indicated that they switched from NSCF to HP recycled fluting in the past for the same end-application, while this proportion with regard to switching from SCF to HP recycled fluting is even higher, 63%.77

(80) Market participants – competitors and customers alike – stated in the market investigation that for certain applications substitutability is possible by increasing the grammage of the lower grade fluting.78 Furthermore, it should be also taken into account that the strength parameters of the final product are dependent not only on the quality of the fluting but also on the overall design of the box. Therefore, the lower quality of (HP) recycled fluting might be further balanced with e.g. the usage of kraftliners instead of testliners.79

(81) The increasing market penetration of recycled fluting is also supported by the fact that while the demand for virgin wood fibre fluting is relatively constant, the recycled fluting consumption increased significantly in the past years.

(82) As a competitor explained, "this product [HP recycled fluting] is fairly new and has been on the rise for the past 15 years. [A competitor] used to have a mill producing a grade that could be referred to as semi-semi- fluting, but shut this mill down as HP recycled fluting completely replaced this product in the market."80

(83) The Commission notes that this trend is likely to continue because the growing demand for corrugated packaging in the EEA, as well as environmental policies promoting recycling, would further incentivise recycled fluting suppliers to develop (HP) recycled fluting with even better performance characteristics.

(84) Consequently, the Commission considers that the market presence of the Parties on a strictly defined NSCF-SCF market does not give a true indication of their competitive strength.

(85) In effect, given that a proportion of the NSCF production of Powerflute faces no competition from Mondi's SCF, and a small proportion faces competition from both SCF and HP recycled fluting, and that a big proportion of Mondi's SCF production faces competition from HP recycled fluting, it seems that the market segment on which NSCF and SCF compete with each other, and only with each other, is rather limited.

(86) It is, however, impossible to accurately determine the size and scope of this market segment due to the lack of transparency with regard to fluting volumes used for a specific end-application and the fact that customers have different views on substitutability even with regard to the same end-application.

Closeness of competition

(87) The market investigation indicated that the Parties are not perceived as particularly close competitors by customers.

(88) Indeed, the vast majority of the respondents stated that they do not purchase Mondi's and Powerflute's product for the same end-application.81 Furthermore, the majority of Mondi's customers would not turn to Powerflute if Mondi stopped supplying them or supplied them at significantly worse conditions82 and vice versa.83

(89) Moreover, when asked about the three closest competitors of Mondi and Powerflute, respectively, the majority of customers did not mention the Parties as one of each other's closest competitors and no customer ranked Mondi as Powerflute's closest competitor. The replies suggest that the market sees rather other NSCF suppliers – namely BillerudKorsnäs and Stora Enso - as Powerflute's closest competitors. 84

(90) Based on the above, the Commission considers that the Parties exert only a limited competitive constraint on each other pre-Transaction.

Available volumes

(91) Based on feedback of market participants on the tightness of the fluting market,85 the Commission also investigated whether the Transaction would have a negative effect on the volumes of virgin wood fibre fluting available within the EEA.

(92) Although the EEA production of virgin wood fibre fluting currently exceeds the EEA demand, customers experience shortages due to the fact that a significant proportion of NSCF and SCF is exported, mainly to Asia and South America.

(93) The market investigation however showed that market participants do not expect the Transaction to negatively impact the available NSCF/SCF volumes in the EEA.86 Furthermore, additional capacities in particular for NSCF – […] – are expected in the next 5 years.

4.2.1.4.Conclusion

(94) Therefore, based on the limited size of the market segment on which only NSCF and SCF compete, the relatively limited competitive constraint that the Parties appear to exert on each other pre-Transaction and the market investigation results indicating that the Transaction would not negatively impact the volume of virgin wood fibre fluting available in the EEA, the Commission considers that the Transaction does not raise serious doubts as to its compatibility with the internal market with regard to horizontal non-coordinated effects in the EEA in respect of fluting, regardless of the exact product market definition.

4.2.2.Vertical non-coordinated effects – fluting and corrugated packaging

(95) If the relevant product market is defined as encompassing only virgin wood fibre fluting, i.e. both NSCF and SCF, or NSCF87, an affected vertical link arises pursuant to the Transaction, as Mondi is active downstream of this market, in the production and supply of corrugated packaging (sheets and boxes).

(96) The Commission considers that the Transaction would not lead to competition concerns with regard to vertical non-coordinated effects irrespective of the market definition upheld for the following reasons.

(97) As regards customer foreclosure, the merged entity would not have the ability to foreclose NSCF/SCF upstream competitors. First, Mondi's estimated market share on a downstream market for the manufacture and sale of corrugated sheets or boxes is below [5-10]% in the EEA, and would not differ significantly and in any case not be higher than 30%, irrespective of any sub-segment considered.88 Second, for NSCF/SCF based corrugated packaging Mondi's market share is [0- 5]% and it faces competition from larger suppliers such as International Paper, DS Smith and Smurfit Kappa, which have a market share of [10-20]%, [5-10]% and [5-10]% respectively.89 As such, competing virgin wood fibre fluting producers90 have sufficient other customers to sell their products to.

(98) As regards input foreclosure, the merged entity would not have the ability to foreclose downstream competitors. First, alternative NSCF/SCF suppliers are present (see also section 4.2.1.1.). Second, corrugated packaging made from NSCF/SCF only accounts for a small proportion of the total sales of corrugated packaging, so that potential input foreclosure behaviour is unlikely to successfully marginalise Mondi's downstream competitors. Third, Mondi's NSCF/SCF demand for its corrugated packaging activities is insignificant on an EEA-wide basis, accounting for […]% of the total NSCF/SCF supply in the EEA.91 Mondi's demand is unlikely to increase in the future as it does not have any corrugator plants in those EEA countries with the highest NSCF/SCF demand due to their fruit and vegetable industry (i.e. France, Italy and Spain), […]. Therefore, Mondi simply could not internalise Powerflute's NSCF production.

(99) The market investigation generally confirmed that market participants consider that vertical non-coordinated effects are unlikely to materialise post-Transaction, and various especially larger manufacturers of CCM products do not expect Mondi to be able to internalise Powerflute's input for its own downstream activities.92

(100) In light of the above, the Commission considers that the Transaction does not raise serious doubts as to its compatibility with the internal market as a result of vertical non-coordinated effects in relation to virgin wood fibre fluting (i.e. both NSCF and SCF), or NSCF, and corrugated packaging, and this irrespective of the market definition upheld.

5. CONCLUSION

(101) For the above reasons, the European Commission has decided not to oppose the notified operation and to declare it compatible with the internal market and with the EEA Agreement. This decision is adopted in application of Article 6(1)(b) of the Merger Regulation and Article 57 of the EEA Agreement.

For the Commission

1 OJ L 24, 29.1.2004, p. 1 (the 'Merger Regulation'). With effect from 1 December 2009, the Treaty on the Functioning of the European Union ('TFEU') has introduced certain changes, such as the replacement of 'Community' by 'Union' and 'common market' by 'internal market'. The terminology of the TFEU will be used throughout this decision.

2 OJ L 1, 3.1.1994, p. 3 (the 'EEA Agreement').

3 Publication in the Official Journal of the European Union No C 137, 19.04.2018, p. 4.

4 M.8831 – Mondi/Powerflute – Article 22 Decision, of 14 March 2018.

5 Both Mondi and Powerflute manufacture wood pulp. Powerflute does not, however, sell pulp on the market but uses everything captively. Also Mondi uses captively the vast majority of the pulp it produces. Mondi's merchant sales of market pulp (a type of chemical pulp that is generally delivered as sheeted bales and used in the production of paper and tissue product) are minimal and its estimated market share is [0-5]%. See paras. 154-157 of the Form CO.

6 On the upstream market, for the purchase and sale of wood, Mondi harvests its own trees and uses only its own wood resources but does not sell wood. Powerflute procures wood through its subsidiary Harvestia. Harvestia has a [0-5]% market share on the market for the procurement and sale of wood. On the downstream market for wood pulp, Mondi has a market share in the sale of market pulp of [0- 5]%. See paras. 147 et seq of the Form CO.

7 Nordic birch is ideal for fluting because of its strong and short fibres, as well as the high content of hemicellulose, a natural starch-like compound which provides protection against the degrading effect that humidity penetration has on wood fibre.

8 M.3935, Jefferson Smurfit/Kappa, para. 18; M.6682, Kinnevik/Billerud/Korsnäs, para. 56-57; M.7558, DS Smith/Duropack, para. 9.

9 A weaker performance of a certain grade can be compensated by using a higher grammage of that grade.

10 See replies to questions 7 and 7.1 of Questionnaire Q1 – CCM Customers; Minutes of a conference call with a competitor on 4 April 2018, para. 7; Minutes of a conference call with a customer on 23 March 2018, para. 3.

11 Replies to question 8 of Questionnaire Q1 – CCM Customers.

12 Replies to question 9 of Questionnaire Q1 – CCM Customers.

13 Minutes of a conference call with a competitor on 4 April 2018, para. 7.

14 This is the chemical process whereby wood chips are soaked and heated/cooked using a chemical solution, to enable the fibres to be separated from the wood.

15 Minutes of a conference call with a competitor on 4 April 2018, para. 10.

16 Minutes of a conference call with a competitor on 7 March 2018, para. 16.

17 On average, virgin wood fibre CCM products appear to be at least 20% more expensive than recycled CCM products, see Minutes of conference call with customer on 5 March 2018, para. 8; Minutes of a conference call with a customer on 3 April 2018, para. 6; Minutes of conference call with competitor on 4 April 2018, para. 16; Replies to questions 10, 10.1, 11 and 11.1 of Questionnaire Q1 – CCM Customers; Replies to question 16.1 of Questionnaire Q2 – Competitors.

18 Replies to questions 10 and 11 of Questionnaire Q1 – CCM Customers; Replies to question 16 of Questionnaire Q2 – Competitors.

19 One of these respondents to the market investigation estimated that only for 10 to 20% of the SCF applications, switching to HP recycled fluting is possible. See Replies to question 10.1 of Questionnaire Q1 – Customers; 16.1 of Questionnaire Q2 – Competitors; Minutes of a conference call with a customer on 3 April 2018, para. 6; Minutes of a conference call with a competitor on 11 April, para. 6.

20 Reply to Question 10.1 of Questionnaire Q1 – CCM Customers.

21 Minutes of a conference call with a competitor on 7 March 2018, paras. 5, 7.

22 Minutes of a conference call with a competitor on 7 March 2018, paras. 11, 13.

23 Replies to questions 10 and 11 of Questionnaire Q1 – CCM Customers; Replies to question 16 of Questionnaire Q2 – Competitors; Minutes of a conference call with a competitor on 26 March 2018, para. 7; Minutes of a conference call with a customer on 12 April, para. 12.

24 Minutes of a conference call with a competitor on 26 March 2018, para. 7; Minutes of a conference call with another competitor on 26 March 2018, para. 7; Minutes of a conference call with a customer on 12 April 2018, para. 12.

25 See replies to question 12 of Questionnaire Q1 – CCM Customers.

26 Minutes of a conference call with a competitor on 23 March 2018, paras. 6-7; Minutes of a conference call with a customer on 3 April 2018, para. 5.

27 Minutes of a conference call with a competitor on 26 March 2018, para. 6; Minutes of a conference call with a customer on 6 March, para. 4, 5.

28 Minutes of a conference call with a competitor on 26 March 2018, paras. 4-5; Minutes of a conference call with a competitor on 4 April, para. 12.

29 Replies to questions 10 and 11 of Questionnaire Q1 – CCM Customers; Replies to question 16 of Questionnaire Q2 – Competitors.

30 For example, on the basis of Italian law, i.e. the Health Ministry Decree of 21 March 1973 on the Hygiene rules for packaging, containers and utensils intended to come into contact with foodstuffs or personal-use products, packaging must consist exclusively of virgin raw material in case of direct contact with food. The most frequently quoted practical example in this context is that of pizza boxes, which should consist of only NSCF as a result of the aforementioned law.

31 Replies to question 10.1 of Questionnaire Q1 – CCM Customers; Replies to question 16.1 of Questionnaire Q2 – Competitors; Minutes of a conference call with a competitor on 11 April 2018, para. 6; Minutes of a conference call with a customer on 23 March 2018, para. 15; Minutes of a conference call with a customer on 26 March 2018, para. 2, 4.

32 Minutes of a conference call with a competitor on 7 March 2018, para 7.

33 Minutes of a conference call with a competitor on 3 April 2018, para. 10.

34 Replies to questions 10, 11 and 12 of Questionnaire Q1 – CCM Customers; Replies to question 16 Questionnaire Q2 – Competitors.

35 Virgin wood fibre fluting is made (mainly) from pulp from virgin wood fibres, whereas recycled fluting is made out of waste paper.

36 Replies to questions 10, 11 and 11.1 of Questionnaire Q2 – Competitors; Minutes of a conference call with a competitor on 7 March 2018, para. 19; Minutes of a conference call with a competitor on 26 March 2018, para. 18-19. A market respondent specified that such investment would take approximately 2,5 years and cost between EUR 500 and 600 million for a production plant with a capacity similar to that of Powerflute, see Minutes of a conference call with a competitor on 4 April 2018, para 4.

37 See for example Minutes of a conference call with a competitor on 23 March 2018, para. 2; Minutes of a conference call with a competitor on 4 April 2018, para. 11; Minutes of a conference call with a competitor on 11 April 2018, para. 6.

38 Minutes of a conference call with a competitor on 26 March 2018, para. 2; Minutes of a conference call with a customer on 3 April 2018, para. 4-5.

39 Minutes of a conference call with a competitor on 3 April 2018, para. 6.

40 Minutes of a conference call with a competitor on 11 April 2018, para. 7.

41 Replies to question 17 of Questionnaire Q2 – Competitors. The same applies to corrugated boxes, for that matter. A market respondent explained that overall, it offers a total of up to 1000 different designs of corrugated boxes. See Minutes of a conference call with a competitor on 4 April 2018, para. 14, 17.

42 Replies to question 16.1 of Questionnaire Q2 – Competitors.

43 Minutes of a conference call with a competitor on 11 April 2018, para. 11.

44 M.7558, DS Smith / Duropack, para. 9; IV/M.499, Jefferson Smurfit/Saint Gobain, para. 15.

45 In 2017, approximately [...]% of Mondi's total sales of CCM products was exported out of the EEA, and for Powerflute this was more than […]%, see para. 120 and figure 21 of the Form CO.

46 Replies to questions 15 and 15.1 of Questionnaire Q1 – CMM Customers.

47 Replies to questions 15.2, 15.3, 18 and 19 of Questionnaire Q1 – CCM Customers; Replies to questions 20, 20.1, 21 and 22 of Questionnaire Q2 – Competitors.

48 Para. 120 of the Form CO.

49 Para. 140 of the Form CO.

50 See cases COMP/M.7558 DS Smith/Duropack, para. 11; COMP/M.3935 Jefferson Smurfit/Kappa, paras. 22 and 26; COMP/M.2391 CVC/Cinven/AssiDomän, paras. 13-14; COMP/M.2032 SCA Packaging/Metsä Corrugated, paras. 12-15.

51 See cases COMP/M.7558 DS Smith/Duropack, para. 11; COMP/M.6512 DS Smith/SCA Packaging, para. 68; COMP/M.2032 SCA Packaging/Metsä Corrugated, paras. 13; IV/M.1418 SCA Packaging/Rexam, para. 13.

52 See cases COMP/M.7558 DS Smith/Duropack, para. 14; COMP/M.6512 DS Smith/SCA Packaging, para. 94; IV/M.1418 SCA Packaging/Rexam, para. 10.

53 Para. 139 of the Form CO

54 See cases COMP/M.7558 DS Smith/Duropack, para. 12; COMP/M.6512 DS Smith/SCA Packaging, paras. 74-75; COMP/M.3935 Jefferson Smurfit/Kappa, para. 23; COMP/M.2391 CVC/Cinven/AssiDomän, para. 25; COMP/M.2032 SCA Packaging/Metsä Corrugated, paras. 23-24; IV/M.1418 SCA Packaging/Rexam, paras. 19-20.

55 See cases COMP/M.7558 DS Smith/Duropack, para. 15; COMP/M.6512 DS Smith/SCA Packaging, para. 109; COMP/M.3935 Jefferson Smurfit/Kappa, para. 27; COMP/M.2391 CVC/Cinven/AssiDomän, para. 28; COMP/M.2032 SCA Packaging/Metsä Corrugated, paras. 21-22; IV/M.1418 SCA Packaging/Rexam, paras. 16-18.

56 Replies to question 20.1 of Questionnaire Q2 – Competitors, minutes of a conference call with a competitor on 3 April 2018, para. 11; and minutes of a conference call with a customer on 7 March 2018, para. 2.

57 Replies to question 20 of Questionnaire Q2 – Competitors and to question 9 of Questionnaire Q3 – Customers – corrugated packaging.

58 Replies to question 19.5 of Questionnaire Q2 – Competitors and to question 7 of Questionnaire Q3 – Customers – corrugated packaging, as well as minutes of conference calls with customers on 26 March 2018 (para. 12) and 3 April 2018, (para. 8).

59 See Figure 29 of the Form CO and submission of competitors on 26 March 2018 and 13 April 2018.

60 The Commission used the volume data as regards imports as provided by the Notifying Party in this exercise.

61 Para.127 of the Form CO.

62 Para.128 of the Form CO.

63 Paras.130-131 of the Form CO.

64 Paras. 132-133 of the Form CO.

65 Para. 134 of the Form CO.

66 See for example Minutes of a conference call with a customer on 11 April 2018, para. 10: "[…] there are some applications that require NSCF and there is simply no ability to substitute (even to SCF).".

67 See Replies to question 16.1 of Questionnaire Q2 – Competitors; Replies to question 10.1 of Questionnaire Q1 – CCM Customers.

68 Pursuant to the Health Ministry Decree of 21 March 1973 on the Hygiene rules for packaging, containers and utensils intended to come into contact with foodstuffs or personal-use products.

69 See Replies to question 10.1 of Questionnaire Q1 – CCM Customers; Minutes of a conference call with a customer on 3 April 2018, paras. 7-8.

70 Minutes of a conference call with a customer on 7 March 2018, para. 10.

71 It should be noted that there are differences between the different types of fruits. While for citrus fruit– which are heavy with a high moisture content – the use of NSCF is warranted, apples can be transported even in boxes made out of recycled fluting. […]. (See Figure 19 of the Form CO and para. 6.4 of the Notifying Party's submission on 30 April 2018.)

72 Replies to question 16.1 of Questionnaire Q2 – Competitors; Replies to question 10.1 of Questionnaire Q1 – CCM Customers; Minutes of a conference call with a customer on 7 March 2018, paras. 7-8; Minutes of conference calls with competitors on 23 March 2018 (para. 15) and on 26 March 2018 (para. 6).

73 See para. 97 of the Form CO and para. 4.1 of the Notifying Party's submission on 30 April 2018.

74 Minutes of a conference call with a customer on 7 March 2018, para. 7.

75 Minutes of conference calls with customers on 7 March 2018 (para. 4-11) and 3 April 2018, para. 6.

76 Minutes of a conference call with a customer on 7 March 2018, para. 9.

77 Replies to question 12 of Questionnaire Q1 – CCM Customers.

78 Replies to question 16.1 of Questionnaire Q1 – CCM Customers; Replies to question 10.1 of Questionnaire Q2 – Competitors; Minutes of a conference call with a competitor on 26 March 2018, para. 5, 7; Minutes of a conference call with a customer on 11 April 2018, para. 10.

79 Replies to questions 16.1 and 16.2 of Questionnaire Q1 – CCM Customers and Figure 19 of the Form CO.

80 Minutes of a conference call with a competitor on 4 April 2018, para. 15.

81 Replies to question 21 of Questionnaire Q1 – CCM Customers.

82 Replies to question 22.2 of Questionnaire Q1 – CCM Customers.

83 Replies to question 22.1 of Questionnaire Q1 – CCM Customers.

84 Replies to question 22 of Questionnaire Q1 – CCM Customers as well as minutes of a conference call with a customer on 7 March 2018, para. 6.

85 See e.g. Minutes of conference calls with customers on 7 March 2018 (paras. 15-19) and 3 April 2018, paras. 16-17.

86 Replies to question 40 of Questionnaire Q1 – CCM Customers and question 39 of Questionnaire Q2 – Competitors.

87 According to the Commission's market reconstruction, Powerflute's estimated EEA-market share on a potential market encompassing only NSCF is [30-40]%.

88 As confirmed by the Notifying Party in response to RFI 1 of 8 May 2018.

89 Para. 140 of the Form CO.

90 Other European virgin wood fibre fluting producers such as BillerudKorsnäs and Stora Enso produce mainly NSCF.

91 Para. 141 of the Form CO.

92 Minutes of a conference call with a competitor on 3 April 2018, para. 23; Minutes of a conference call with a competitor on 7 March 2018, para. 21; Minutes of a conference call with a competitor on 4 April 2018, para. 24; Minutes of a conference call with a competitor on 26 March 2018, para. 16.