Commission, April 24, 2015, No M.7550

EUROPEAN COMMISSION

Judgment

CRH / HOLCIM LAFARGE DIVESTMENT BUSINESS

Dear Sir/Madam,

Subject: Case M.7550 - CRH / HOLCIM LAFARGE DIVESTMENT BUSINESS

Commission decision pursuant to Article 6(1)(b) of Council Regulation No 139/20041 and Article 57 of the Agreement on the European Economic Area2

(1) On 18 March 2015, the European Commission received notification of a proposed concentration pursuant to Article 4 of the Merger Regulation by which CRH plc ('CRH' or 'the Notifying Party'), Ireland) acquires within the meaning of Article 3(1)(b) of the Merger Regulation sole control over certain assets of Holcim Ltd ('Holcim') and Lafarge S.A. ('Lafarge')

(2) Holcim and Lafarge are required to divest those assets pursuant to the decision of 15 December 2014 based on Article 6(1)(b) in connection with Article 6(2) of the Merger Regulation, whereby the Commission declared the operation by which Holcim acquires within the meaning of Article 3(1)(b) of the Merger Regulation sole control of the whole of Lafarge, compatible with the internal market subject to conditions and obligations (the 'Commitments').

(3) CRH is acquiring the following assets divested by Holcim and Lafarge: a. the entirety of Holcim's business activities in France, with the exception of its plant at Altkirch and adjacent ready-mix concrete ('RMX') plants and aggregates sites in the Haut-Rhin region, as well as the Montoir import terminal in Northwest France; b. Lafarge's grinding station Ciments Kercim (France); c. the entirety of Lafarge's business activities in La Réunion, with the exception of its shareholding in Ciments de Bourbon; d. the entirety of Holcim's operating assets in Hungary, with the exception of the closed Labatlan cement plant and a plot of land at Nyergesújfalu, the company PULTRANS Kft and the assets at Miskolc; e. the entirety of Lafarge's business activities in Romania; f. the entirety of Holcim's business activities in Slovakia; g.the entirety of Lafarge's business activities in Germany; h. Lafarge's business activities in the United Kingdom (“UK”), currently carried out by Lafarge Tarmac, with the exception of: (i) the Cauldon cement plant and certain related assets; and (ii) the Cookstown cement plant in Northern Ireland; (hereinafter referred to as 'the Divestment Business')

(4) CRH and the Divestment Business are together referred to as 'the Parties'. The entity resulting from the Holcim / Lafarge merger is referred to in this decision as 'LafargeHolcim'.

1.THE PARTIES

(5) CRH is a global producer and supplier of building materials, including grey cement, ready-mix concrete, aggregates and asphalt.

(6) Holcim is a global supplier of building materials, and particularly of cement, aggregates, ready-mix concrete ("RMX"), asphalt, cementitious materials and related services. It operates in more than 70 countries.

(7) Lafarge is a global supplier of cement, aggregates, RMX and other building materials. Lafarge is active in 64 countries and has some 65,000 employees.

(8) The Divestment Business includes integrated cement plants, RMX plants, aggregates quarries, grinding stations, cement terminals, manufacturing facilities for lime, concrete blocks and mortar as well as related services.

2.THE OPERATION

(9) On 31 January 2015, CRH made a binding and irrevocable offer to Holcim and Lafarge for the Divestment Business. The offer is conditional upon the relevant social processes and obtaining regulatory and other customary authorisations, including merger control clearance.

(10) Upon acceptance of the offer, CRH, Lafarge and Holcim will enter into a share purchase agreement ('SPA') by which CRH will acquire the share capital of the companies belonging to the Divestment Business ('the Notified Transaction'). The Notified Transaction therefore consists of the acquisition of sole control by CRH of the whole of the Divestment Business and constitutes a concentration within the meaning of Article 3(1)(b) of the Merger Regulation.

3.EU DIMENSION

(11) The undertakings concerned have a combined aggregate world-wide turnover of more than EUR 5 000 million (CRH: 18,032 EUR million; Divestment Business: […] EUR million). Each of them has an EU-wide turnover in excess of EUR 250 million (CRH: […] EUR million; Divestment Business: […] EUR million), but they do not achieve more than two-thirds of their aggregate EU-wide turnover within one and the same Member State. The notified operation therefore has an EU dimension within the meaning of Article 1(2) of the Merger regulation.

4. OVERVIEW OF PRODUCTS AND THE PARTIES' ACTIVITIES

4.1. Overview of the building materials industry

(12) The Notified Transaction concerns the building materials industry and relates to grey cement, ready-mix concrete, aggregates, asphalt, contract surfacing, cementitious materials, as well as certain other products (clinker, white cement, and concrete products).

(13) Cement is one of the main input products in modern construction. It is a fine powder produced from limestone, alumino-silicate and other constituents. Cement is used in the building and construction sector because it has a superior power to harden once mixed with water, and to bind other materials for stability and strength. Cement is used as an intermediary product mainly for the production of ready-mixed concrete, concrete products and mortar. There are two main types of cement: white cement and grey cement.3

(14) The main difference between white and grey cement lies in the particular quality of limestone used for the production of white cement. Furthermore, white cement is used for different purposes (in particular reflecting esthetical/optical aspects), is produced in comparably limited quantities and is more expensive than grey cement. CRH does not manufacture white cement in the EEA; it sources white cement from third parties and resells it.

(15) Cement is produced by grinding clinker and other cementitious materials. Clinker is the main ingredient in the production of cement, produced at high temperatures from limestone and other constituents in cement kilns. In some cases, mineral components and other cementitious materials are added to the mixture by either grinding them together with clinker or blending separately ground materials together.

(16) In this Decision, the term alternative cementitious materials refers to substances other than clinker that have cementitious, or hydraulic binding properties and that are used as supplementary materials in the production of cement and concrete. The most common alternative cementitious materials are fly ash (a by-product of coal combustion in thermal power plants) and blast furnace slag (a by-product in the production of iron) in the form of granulated blast furnace slag ("GBS") or ground granulated blast furnace slag ("GGBS"). They are added to cement and concrete in order to impart specific characteristics to the end product and to substitute, on the one hand, clinker in the production of cement and, on the other hand, cement in the production of concrete.

(17) Within grey cement, there are a large number of different classes available and further grades can be produced according to customer requirements. Cement classes are defined by strength development and setting times, which are in turn determined by the proportions and nature of the different raw cementitious products used to make that particular cement type.4 The EU standard EN 197-1defines five classes of common cement that comprise Portland cement as a main constituent.

Table 1 - Classes of common cement according to EN 197-15

CEM I | Portland cement | Comprising Portland cement and up to 5% of minor additional constituents |

CEM II | Portland-composite cement | Portland cement and up to 35% of other single constituents |

CEM III | Blast furnace cement | Portland cement and higher percentages of blast furnace slag |

CEM IV | Pozzolanic cement | Portland cement and up to 55% of pozzolanic constituents (volcanic ash) |

CEM V | Composite cement | Portland cement, blast furnace slag or fly ash and pozzolana |

(18) There are generally three types of cement production sites: integrated cement plants, grinding stations and blending stations.6

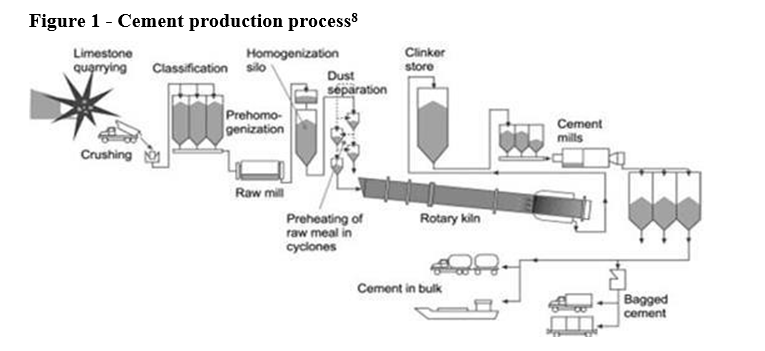

(19) An integrated cement plant is a manufacturing facility that covers the entire cement production process from the mining of raw materials to the dispatching of cement. The production process involves the following steps: (i) raw material extraction or mining from a quarry; (ii) raw material preparation and blending; (iii) raw feed preparation out of the raw materials in the form of meal; (iv) clinker production, which forms the main process of an integrated plant, that is to say converting raw feed in a thermochemical reaction in a cement kiln into the desired calcined mineral ('clinker'); (v) grinding and blending of clinker with gypsum or other components (such as alternative cementitious materials) into the desired cement product; and (vi) storage and handling of cement products, including dispatch.

(20) A grinding station or grinding mill does not include the mining and the thermal process of producing clinker, but only the final grinding, blending and handling steps, with clinker and other raw materials being delivered from a separate plant or sourced elsewhere.

(21) An import terminal is a depot facility dedicated to cross-border supply. This kind of site is typically accessible by navigable water, railway or by road. An import terminal consists of a relevant transport platform and of a silo-type storage installation. An import terminal is a strategic asset enabling a cement manufacturer to supply a territory where it does not operate a production site.

(22) Cement is sold both bulk and bagged.7 Bags containing about 25-30 kg of cement are sold through do-it-yourself stores and building material retailers whereas bulk cement meets the demand of RMX plants, plants producing concrete products and building sites.

(23) Ready-mix concrete ("RMX") is produced by mixing cement and aggregates with water. Concrete is mixed either on-site or, more commonly, in a dedicated plant before being subsequently transported to the point of use in specific mixer trucks. Transport time and distance are limited, however, due to the inherent characteristics of ready-mix concrete to set because of cement reacting with water.

(24) Aggregates ("AGG") encompass the three primary raw materials used in construction and civil engineering: gravel, crushed rock and sand. Due to the impact of transport costs, aggregates are typically sold locally.

(25) Asphalt is a product manufactured by heating and mixing aggregates and a binding agent (normally bitumen). It is used for surfacing roads, car parks, footpath pavements, airport runways, and other sites.

(26) The works associated with the construction and maintenance of roads and other surfaces constitute contract surfacing (also known as contracting, asphalt surfacing, and road maintenance services). Within contract surfacing, asphalt is typically laid onto the prepared foundation layers of a road in layers, with each layer being compacted by paving machines to form the top surface of the road.

4.2.The Parties' activities

(27) The Parties produce and sell cement, ready-mix concrete, aggregates, and other products. The following tables provide an overview of the Parties' activities in the territories of the contracting parties to the EEA Agreement for the various products and services concerned with grey shaded areas indicating an overlap of activities.

(28) Concerning grey cement, the Parties' activities overlap in Belgium, France, Poland, Slovakia and the United Kingdom.

Table 2 - Grey cement sales in the EEA9

| CRH | DivCo |

| CRH | DivCo |

| CRH | DivCo |

AT | No | Yes | DE | No | Yes | RO | No | Yes |

BE | Yes | Yes | HU | No | Yes | SK | Yes | Yes |

CZ | No | Yes | IE | Yes | No | ES | Yes | No |

FI | Yes | No | NL | Yes | No | UK | Yes | Yes |

FR | Yes | Yes | PL | Yes | Yes |

| ||

(29) Concerning white cement, the Parties' activities overlap in Belgium, Germany and the Netherlands.

(30) Concerning RMX, the Parties' activities overlap in Hungary and in the United Kingdom.

Table 3 – RMX facilities in the EEA

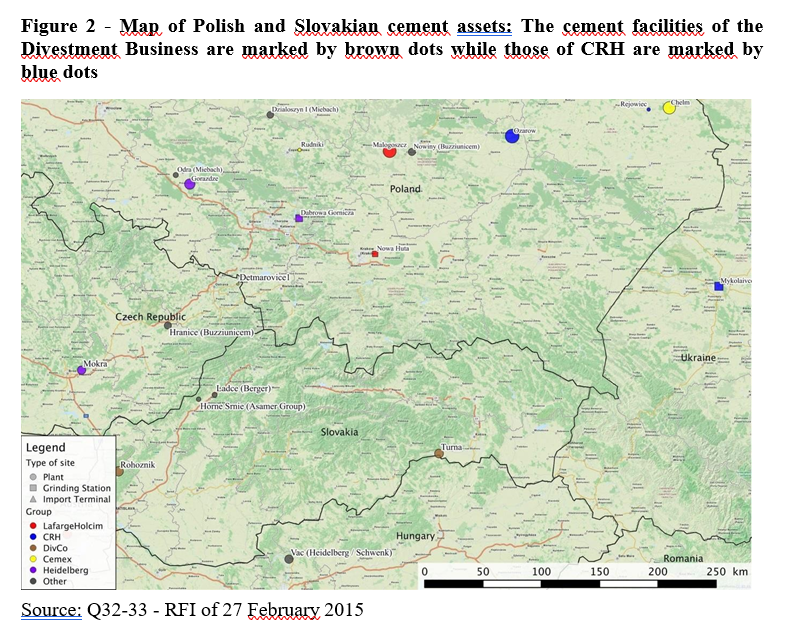

| CRH | DivCo |

| CRH | DivCo |

FR | No | Yes | PL | Yes | No |

DE | No | Yes | RO | No | Yes |

HU | Yes | Yes | SK | No | Yes |

IE | Yes | No | UK | Yes | Yes |

NL | Yes | No |

| ||

(31) The Parties' sourcing of cementitious materials overlaps in Germany and Spain.

Table 4 – Sourcing of alternative cementitious materials in the EEA

| CRH | DivCo |

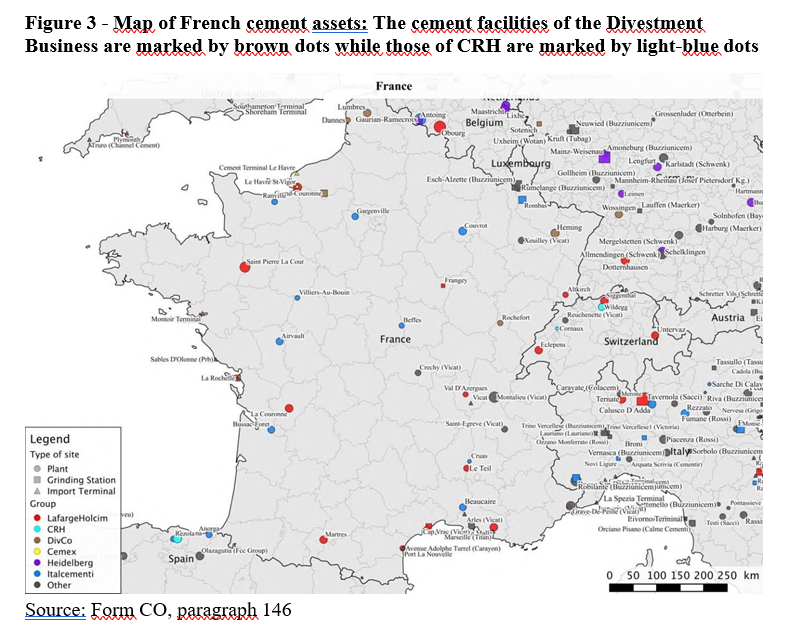

| CRH | DivCo |

AT | No | Yes (S) | NL | Yes (S, FA) | No |

CZ | No | Yes (S, FA) | PL | Yes (S, FA) | No |

FI | Yes (S, FA) | No | RO | No | Yes (S, FA) |

FR | No | Yes (S, FA) | SK | No | Yes (S, FA) |

DE | Yes (S, FA) | Yes (S, FA) | ES | Yes (S, FA) | Yes (S) |

IE | Yes (FA) | No | UK | No | Yes (S, FA) |

FA - fly ash, S – slag

(32) Concerning sales of alternative cementitious materials, the Parties' activities do not overlap.

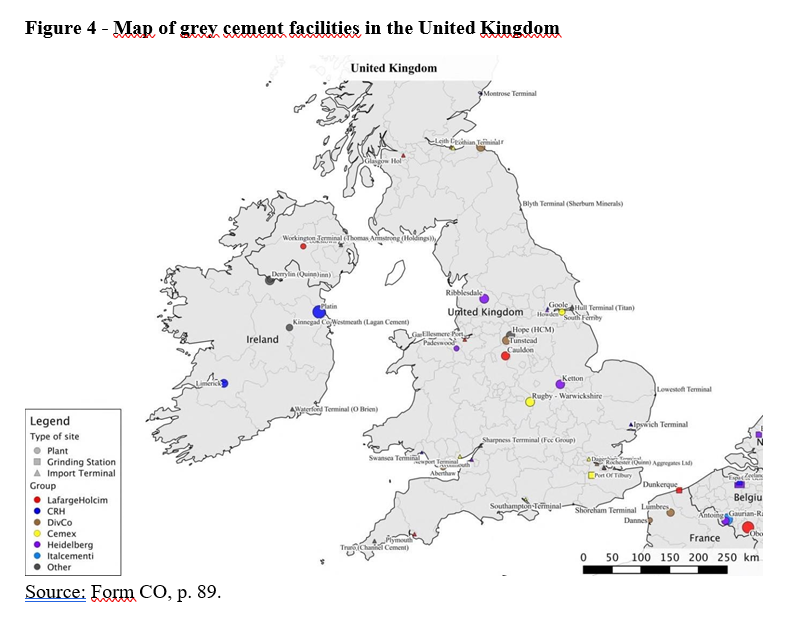

Table 5 – Sales of alternative cementitious materials to third parties in the EEA

| CRH | DivCo |

| CRH | DivCo |

BE | Yes | No | NL | Yes | No |

IE | Yes | No | UK | No | Yes |

(33) Concerning aggregates, the Parties' activities overlap in Slovakia and in the United Kingdom.

Table 6 – Aggregates quarries in the EEA

| CRH | DivCo |

| CRH | DivCo |

FR | No | Yes | RO | No | Yes |

IE | Yes | No | SK | Yes | Yes |

NL | Yes | No | UK | Yes | Yes |

PL | Yes | No |

|

|

|

(34) Concerning asphalt and contract surfacing, the Parties' activities overlap in the United Kingdom.

5.MARKET DEFINITION AND COMPETITIVE ASSESSMENT

5.1. Grey cement

5.1.1. Relevant product market definition

5.1.1.1. Past decisional practice

(35) There are two main types of cement: white cement and grey cement. In past decisions, the Commission defined distinct product markets for white cement and grey cement.10

(36) Concerning grey cement, the Commission has considered that the market should not be further segmented according to grades or classes (CEM I to CEM V).11 The Commission also stated that the market for grey cement could be further segmented according to whether grey cement is sold bulk or bagged, but left open the precise product market definition.12

5.1.1.2.The Notifying Party's arguments

(37) The Notifying Party considers there is no reason to deviate from the Commission's decisional practice that white cement constitutes a product market distinct from grey cement and that grey cement of all grades comprises a single relevant product market. The Notifying Party submits, however, that there is a single product market for the manufacture and sale of grey cement, irrespective of both packaging (bagged and bulk).

5.1.1.3.Responses to the market investigation

(38) As regards the distinction between white and grey cement, respondents to the market investigation supported the Commission's findings in past decisions and the Notifying Party's view that they constitute separate product markets. Competitors and customers that responded to the market investigation almost unanimously made a distinction between white and grey cement. Those customers also indicated that white cement has a much higher price than grey cement and is mostly employed for aesthetic reasons.13 Those competitors also noted that the markets for grey and white cement differ in terms of raw materials used, industrial purposes and selling prices.14

(39) As regards the distinction between bagged and bulk cement, respondents to the market investigation supported the Commission's findings in past decisions that the market for grey cement could in principle be further segmented according to whether grey cement is sold bulk or bagged.

(40) First, although nearly all suppliers of grey cement that responded to the market investigation indicated that they are active both in bulk and bagged cement, they also indicated that additional investment is required to switch production from bulk cement to bagged cement at a specific plant if it is not equipped with a bagging facility. Respondents estimated lead times to complete the investment at 9-24 months with an average investment of EUR 5 million.15

(41) Second, a vast majority of respondent customers argued that they are unable to substitute bagged with bulk cement in their operations, and vice versa. They reported differences in terms of customers, prices and performance. For instance, manufacturers of RMX and concrete products purchase bulk cement as they need larger quantities and are equipped with silos to preserve the cement. By contrast, bagged cement is widely dedicated to smaller building sites and do-it-yourself retailers.16

5.1.1.4. Conclusion on the relevant product market

(42) In light of past decisional practice, the Notifying Party’s arguments and the responses to the market investigation, the Commission considers that for the purposes of this Decision, the relevant product market is the overall market for grey cement. The exact product market definition can be left open, however, since the competitive assessment would not change even if a narrower segmentation between bagged and bulk grey cement were considered.

5.1.2. Relevant geographic market definition

5.1.2.1. Past decisional practice

(43) In past decisions, the Commission has considered that the geographic market for grey cement consists of a group of geographic markets centred on different cement plants, overlapping one another. The scope of the relevant geographic markets was determined by the distance from the plant at which cement may be sold.17 In Holcim / Cemex West, the Commission considered that the appropriate radii around the relevant grey cement plants to be taken into account were 150 km and 250 km and in Cemex / Holcim Assets, the market was defined as circles of 150 km radii around the cement plants. In Holcim / Lafarge the Commission also considered that the relevant geographic markets should be defined as circular areas of 150 km and 250 km around the relevant cement plants, reflecting the distance up to which cement suppliers can economically sell cement.

5.1.2.2. The Notifying Party's arguments

(44) The Notifying Party argues that the maximum distance from each grey cement plant or depot over which it would be economically feasible to transport grey cement is approximately 150-250 km. This distance may vary depending on numerous factors such as topography, access to transport and location of other grey cement facilities. The Notifying Party, however, considers that the relevant geographic market for grey cement should be defined as areas of 150 km or 250 km radius around each plant, in keeping with the Commission's past decisional practice.

5.1.2.3. Responses to the market investigation

(45) Respondents to the market investigation stated that transport costs are significant in the sale of grey cement and determine how far away a cement plant can still viably compete with its product.18 Respondents also indicated that almost all cement sales take place within radii of 150km to 250km of plants.19

(46) On average, [70-80]% of all CRH' sales in the EEA are sold within a distance of 150 km from its plants and [80-90]% of the sales take place within 250 km. For the Divestment Business, the corresponding figures are [80-90]% and [90-100]%.

5.1.2.4. Conclusion on the relevant geographic markets

(47) In light of past decisional practice, the Notifying Party’s arguments and the responses to the market investigation, the Commission considers that the relevant geographic markets in this case should be defined as circular areas of 150 km and 250 km around the relevant cement plants, reflecting the distance up to which cement suppliers can economically sell cement.

(48) The Commission acknowledges, however, that defining the relevant geographic markets as circles around a grey cement supplier’s plant may lead to the inclusion of customers facing differing supply conditions, in particular a differing number of close-by supply alternatives. Grouping together only customers facing similar supply conditions would, however, lead to the definition of many different geographic markets. The Commission therefore uses the approach of drawing circles around the Parties' plants which include the customers for which the respective plant is a potential source of supply. In any case, the fact that, within a given circle, customers may face differing supply conditions will be taken into account in the ensuing competitive assessment. The Commission considers it pertinent to assess circles with different sizes, in particular circles with radii which include most actual customers of the respective plants (150 km in this case) as well as circles with larger radii which also include most potential customers (250 km in this case).

(49) The markets should also not be limited by national borders. This is for several reasons.

(50) First, there are significant trade flows across national borders in certain parts of the EEA.20 The market investigation indicated that barriers to cross-border trade of grey cement are limited as many customers said they would consider procuring grey cement across national borders.21

(51) Second, while sometimes customers report a preference for domestically produced cement particularly when it comes to lead time and supply continuity22, imports are considered by a majority as a viable alternative.23 Some major suppliers also reported that imports can sometimes be the source of significant pressure on prices.24

(52) Third, the cross-border nature of cement sales is further reflected by the fact that the operational networks of larger cement producers are structured on a cross- border basis to achieve coverage of geographic regions.

5.1.3.Competitive assessment

5.1.3.1.Methodology for the calculation of market shares

(53) The Parties submitted market share estimates for their activities in grey cement using two main different methodologies: (i) sales market shares based on their actual sales; and (ii) capacity market shares based on their production capacities.25

(54) At the national and EEA level, the Parties' sales and capacity market share estimates are based on data which is available by country. The capacity share estimates at the national and EEA level take into account the capacity of all plants located in the respective Member State and in the EEA.

(55) At the catchment area level, the Parties' market shares are based on circular catchment areas with radii of 150 and 250 km geodesic distance. The details of the calculation of sales and capacity market shares for the catchment areas are explained in recitals (56) to (59). In line with the Commission's previous competitive assessments, the circles are drawn around the Parties' respective plants (plant-centred approach).26 In addition, for certain catchment areas where overlaps are more significant, the Parties have provided market shares for catchment areas drawn around the mid-point between two of the Parties’ plants (this is the mid- point of a straight line drawn between the two plants). This allows an assessment from the perspective of a customer based in that location between the two plants (mid-point approach).

(56) For the calculation of sales market shares, the Parties have used two elements: (i) the total market size of the catchment area; and (ii) the Parties and their competitors' sales in that area. Sales data of competitors have been estimated based on public information. In order to determine the sales for each of the Parties in the market, sales transaction volume data of the Parties has been used.

(57) Catchment area sales market shares are based on the Parties' actual sales in radii of 150 and 250 km geodesic distance drawn around their respective plant or around the mid-points. The size of the market is computed as the product of cement consumption per capita in the respective region or Member State and the population of the catchment area. In line with the Commission's most recent precedent,27 the Parties have used data based on NUTS3 administrative regions28 to estimate their own sales and the size of the local market. Local market shares in catchment areas are calculated based on NUTS3 administrative regions that overlap with the respective catchment area. The local market share of the Parties is the sum of their sales into the overlapping NUTS3 regions divided by the total estimated cement consumption in the same regions.

(58) The sales market shares of competitors are estimated by allocating the market volume minus the Parties' volumes to each competitor in proportion to its production capacity shares in the area. The production capacity share of each competitor is calculated in relation to the total capacity of competitors in the area.

(59) The capacity market shares have been calculated on the basis of two methodologies: (i) taking into account only the capacities of plants located inside the relevant catchment area (standard approach); and (ii) taking into account also the plants outside the relevant catchment area whose radius overlaps with the relevant catchment area (geometric approach). The Commission has analysed the provided capacity market shares based on both methodologies and found that the shares are usually highly similar. It is therefore unnecessary to present both sets of capacity market shares in this Decision.

5.1.3.2. Poland and Slovakia

(60) There is an overlap in grey cement activities between CRH and the Divestment Business in the cross-border region between southern Poland and Slovakia. While CRH does not operate any grey cement facility in Slovakia, it operates two integrated grey cement plants in Poland (Ożarów and Rejowiec). The Divestment Business is active in Slovakia through two integrated grey cement plants at Rohoznik and Turna.

(61) The national sales share of the Divestment Business in Slovakia amounts to [40-50]%. From Poland, CRH exports only limited amounts of grey cement into Slovakia, […]. Even taking these sales into account, CRH’s national sales share in Slovakia only amounts to [0-5]% ([0-5]% disregarding internal sales).

(62) In Poland, CRH has a national sales share of [10-20]%. The Divestment Business only imports limited amounts of grey cement in this country and has a national sales share of [0-5]%.

(63) For the reasons set out in recitals (64) – (70), the Commission finds that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to grey cement in the relevant catchment areas in Poland and Slovakia.

(64) First, at national level, the Notified Transaction will produce only limited increments. Even in Slovakia, where the Divestment Business has a certain presence, the increments on a national scale will be low. If only CRH sales of grey cement to third parties are considered, the increment in Slovakia will amount to approximately [0-5]%, with no change to the existing competitive constraint exerted by the main competitors on the Slovak market, Asamer Group and Povazska/Berger.

(65) Second, the Notified Transaction will produce only limited increments at catchment area level.

(66) In the catchment areas around CRH's Polish plants of Rejowiec and Ożarów, the Divestment Business' sales are low – with increments comprised between [0-5]% and [0-5]%.

(67) As regards the catchment areas around the Divestment Business' plants in Slovakia, while increments are more significant in the 150 and 250 km catchment areas around Turna ([5-10]% and [10-20]% respectively), the combined market shares of the Parties in those catchment areas will be low (approximately [20-30]% in both instances).

Table 7 - Grey cement sales volume shares for all overlapping catchment areas in Poland and Slovakia in 2013

Country | Plant | Plant owner | Radius (km) | Divestment business (%) | CRH (%) | Combined (%) |

Poland | Ożarów | CRH | 150 | [0-5] | [30-40] | [30-40] |

Poland | Ożarów | CRH | 250 | [0-5] | [20-30] | [20-30] |

Poland | Rejowiec | CRH | 150 | [0-5] | [40-50] | [50-60] |

Poland | Rejowiec | CRH | 250 | [0-5] | [30-40] | [30-40] |

Slovakia | Rohoznik | Divestment Business | 150 | [20-30] | [0-5] | [20-30] |

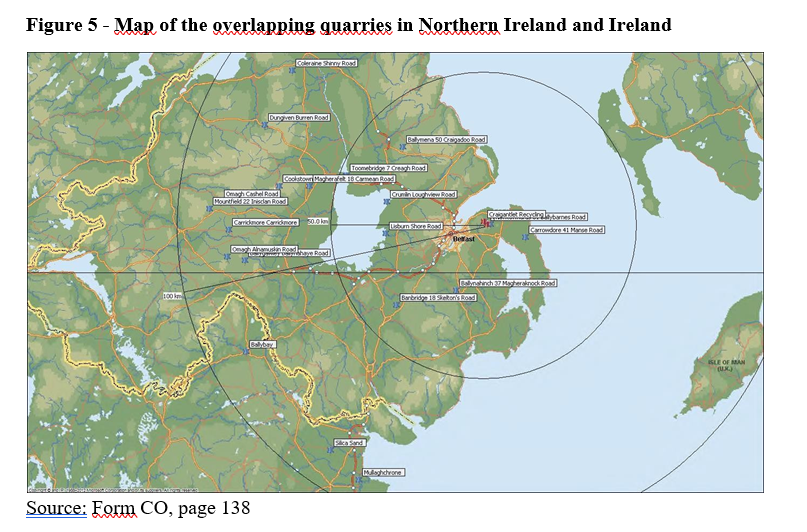

Slovakia | Rohoznik | Divestment Business | 250 | [10-20] | [0-5] | [10-20] |

Slovakia | Turna | Divestment Business | 150 | [10-20] | [5-10] | [20-30] |

Slovakia | Turna | Divestment Business | 250 | [10-20] | [10-20] | [20-30] |

Source: Form CO, paragraph 196

(68) Third, respondents to the market investigation indicated that there is little import export activity in the cross border area between Poland and Slovakia. Explanations given for the limited export activity included low advertising activity and the corresponding lack of information on non-domestic suppliers, cultural and language barriers.29 Moreover, the small differences in prices charged for grey cement on both sides of the border make cross-border purchases less attractive than in other cross-border areas.30

(69) Fourth, respondents to the market investigation noted the availability of alternative suppliers.31 There are a number of competitors active on the grey cement market in Poland and Slovakia, which will compete with the Parties in the relevant catchment areas. These include Heidelberg and entity resulting from the Holcim / Lafarge merger ('LafargeHolcim'). These are big scale operators with an international presence and significant market shares in the relevant markets.

(70) As regards vertical effects, although one competitor raised concerns regarding the possible effects of the Notified Transaction on the downstream RMX markets,32 the Commission considers that the Notified Transaction will not give the Parties either the ability or incentive to foreclose access to supplies to actual or potential rivals. The combined market share in the downstream RMX market will not increase post- transaction: the Divestment Business is not currently present on the Polish RMX market and CRH is not currently present on the Slovak RMX market.33

5.1.3.3. France and Belgium

(71) The activities of the Parties overlap in the production and supply of grey cement in France and in Belgium. Due to the location of the affected catchment areas, the assessment of the Commission focuses on the cross-border region between France and Belgium.

(72) The grey cement production assets of the Divestment Business in France consist of three integrated grey cement plants (in Heming, Lumbres and Rochefort), four active grinding stations (in Dannes, Grand Couronnes, Saint Nazaire and La Rochelle) and one import terminal. The Divestment Business does not have any grey cement facilities in Belgium.

(73) The grey cement production facilities of CRH in Belgium consist of two active grinding stations (in Antwerp and Rieme) and one road depot (in Gent). CRH does not have any grey cement facilities in France.

(74) For the reasons set out in recitals (75) – (78), the Commission considers that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to grey cement in France and in Belgium.

(75) First, at a national level, the Parties' combined market shares will be relatively low. In Belgium, the combined market share will be [5-10]% with an increment of less than [0-5]% from the Divestment Business. In France, the combined market share will be [10-20]% with an increment of [0-5]% from CRH.

(76) Second, the situation does not change at catchment area level. The combined sales shares around the Parties' facilities located in Belgium do not result in any affected market. The combined market shares for catchment areas around the merged entity's facilities in France will amount to between [10-20]% and [20-30]% with increments between [0-5]% and [5-10]%

Table 8 - Sales volume shares for all overlapping catchment areas in Belgium and France in 2013

Country | Site | Site owner | Radius (km) | Divestment Business (%) | CRH (%) | Combined (%) |

Belgium | Rieme | CRH | 150 | [0-5] | [5-10] | [10-20] |

Belgium | Rieme | CRH | 250 | [5-10] | [0-5] | [5-10] |

Belgium | VVM Antwerpen | CRH | 150 | [0-5] | [5-10] | [5-10] |

Belgium | VVM Antwerpen | CRH | 250 | [5-10] | [0-5] | [5-10] |

France | Dannes | Divestment Business | 150 | [10-20] | [5-10] | [20-30] |

France | Dannes | Divestment Business | 250 | [10-20] | [5-10] | [10-20] |

France | Grand- Couronne | Divestment Business | 150 | [20-30] | [0-5] | [20-30] |

France | Grand- Couronne | Divestment Business | 250 | [10-20] | [0-5] | [10-20] |

France | Lumbres | Divestment Business | 150 | [10-20] | [5-10] | [20-30] |

France | Lumbres | Divestment Business | 250 | [10-20] | [5-10] | [10-20] |

Source: Form CO, paragraph 152

(77) Third, customers that responded to the market investigation indicated that, due to the downturn in the construction industry, demand for grey cement has dropped by approximately a quarter between 2007 and 2014.34 Prices have declined and suppliers have significant spare capacities. The Notifying Party estimates spare capacity at its Belgian plants to be above [1-50]%. Respondents to the market investigation also pointed to spare capacities between 25 and 50% in France and in Belgium.35

(78) Fourth, respondents to the market investigation noted the presence of several credible alternative grey cement suppliers in France.36 These alternative suppliers are Cemex (through its subsidiary France Liants), Italcementi (through its subsidiary Ciments Calcia), Titan, Vicat, Carayon, Cimalux and PRB. The merged entity will also face constraints from the remaining assets of Holcim which will be part of LafargeHolcim.

(79) Fifth, barriers to cross-border trade and to imports are low. Respondents to the market investigation pointed to examples of expansion and potential entry, through imports or by new facilities. For instance, Vrac de l'Estuaire, is expected to start operating a grinding station in Le Havre in 2015.37 The vast majority of customers that responded to the market investigation did not consider that the Notified Transaction will have any negative impact on the markets for grey cement in France and Belgium.38

5.1.3.4. United Kingdom

(80) The grey cement activities of the Parties overlap in the United Kingdom.

(81) Although CRH does not operate any grey cement production facilities in the United Kingdom, it is active on that market through its import terminals, located in Swansea, Ipswich, Shoreham, Garston, Howden, Lowestoft and Montrose.

(82) The grey cement assets of the Divestment Business in the United Kingdom comprise three integrated plants, located in Aberthaw (Wales), Dunbar (Scotland) and Tunstead (West Midlands), a bagging and distribution facility in Barnstone, cement depots used for local distribution,39 and two import terminals, situated at Northfleet (with a blender) and at Leith Docks (currently mothballed).

(83) For the reasons set out in recitals (84) to (104) the Commission finds that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to grey cement in the United Kingdom.

National level

(84) There are several reasons why the Notified Transaction will not give raise serious doubts as to its compatibility with the internal market in relation to grey cement at national level.

(85) First, while the Parties will have a combined market share of [20-30]%, the increment is limited ([0-5]%, corresponding to CRH's imports).

(86) Second, the Notified Transaction will allow CRH, which currently imports grey cement into the United Kingdom, to acquire assets enabling it to produce grey cement domestically. Because Lafarge will retain a grey cement plant at Cauldon, the Notified Transaction will increase the number of domestic producers of grey cement in the United Kingdom from four to five.40

(87) Third, aside from domestic grey cement producers, a number of importers active in the United Kingdom will remain. While importers cannot meet the needs of certain customers operating on a national scale that require large volumes of continuous supplies across the country,41 they can supply several catchment areas across the whole territory of the United Kingdom.42 The Notifying Party estimates that approximately 15% of grey cement used in Great Britain in 2013 was imported from other countries.43These volumes will continue playing a role in exerting competitive pressure vis-à-vis domestic producers.

Catchment area level

(88) Although the competitive pressure exerted by CRH’s terminals (and terminals in general) is more local, the Notified Transaction will result in limited market share increases at the catchment area level. In all but two catchment areas, increments will remain below [0-5]%.

Table 9 - Grey cement – United Kingdom Sales shares for 150 and 250km catchment area in 2013

Plant | Plant owner | Radius (km) | Divestment Business (%) | CRH (%) | Combined (%) |

Aberthaw | Divestment Business | 150 | [30-40] | [5-10] | [30-40] |

Aberthaw | Divestment Business | 250 | [20-30] | [0-5] | [20-30] |

Dunbar | Divestment Business | 150 | [40-50] | [0-5] | [40-50] |

Dunbar | Divestment Business | 250 | [40-50] | [0-5] | [40-50] |

Garston Terminal | CRH | 150 | [10-20] | [0-5] | [10-20] |

Garston Terminal | CRH | 250 | [20-30] | [0-5] | [20-30] |

Howden Terminal | CRH | 150 | [10-20] | [0-5] | [20-30] |

Howden Terminal | CRH | 250 | [10-20] | [0-5] | [20-30] |

Ipswich Terminal | CRH | 150 | [20-30] | [0-5] | [20-30] |

Ipswich Terminal | CRH | 250 | [20-30] | [0-5] | [20-30] |

Leith Docks (mothballed) | Divestment Business | 150 | [40-50] | [0-5] | [40-50] |

Leith Docks (mothballed) | Divestment Business | 250 | [40-50] | [0-5] | [40-50] |

Montrose Terminal | CRH | 150 | [40-50] | [0-5] | [40-50] |

Montrose Terminal | CRH | 250 | [40-50] | [0-5] | [40-50] |

Northfleet | Divestment Business | 150 | [20-30] | [0-5] | [20-30] |

Northfleet | Divestment Business | 250 | [20-30] | [0-5] | [20-30] |

Plant | Plant owner | Radius (km) | Divestment Business (%) | CRH (%) | Combined (%) |

Shoreham Terminal | CRH | 150 | [20-30] | [0-5] | [30-40] |

Shoreham Terminal | CRH | 250 | [20-30] | [0-5] | [20-30] |

Swansea Terminal | CRH | 150 | [30-40] | [5-10] | [40-50] |

Swansea Terminal | CRH | 250 | [20-30] | [0-5] | [20-30] |

Tunstead | Divestment Business | 150 | [10-20] | [0-5] | [10-20] |

Tunstead | Divestment Business | 250 | [20-30] | [0-5] | [20-30] |

Source: Form CO, paragraph 257

(89) The more significant increments concern the catchment areas around the Aberthaw integrated plant and the Swansea import terminal in South Wales. These areas are assessed separately below.

(90) As regards the other catchment areas, because of the limited market share increases, the Notified Transaction will not generally bring about any material change in the structure of the market and in the conditions of competitions in the affected catchment areas. Customers who responded to the market investigation also generally did not forecast any negative impact from the Notified Transaction.44 As a partially different picture emerged, however, from the market investigation in relation to the catchment areas around the plant of the Divestment Business at Dunbar, Scotland, where two customers reported potential concerns, these areas are assessed separately below.

South Wales

(91) In the 150 km catchment area around CRH's import terminal at Swansea, in South Wales, the increment will be [5-10]% and the combined market share will amount to [40-50]%. This relatively high market share will be due to the proximity between the CRH import terminal at Swansea and Lafarge’s divested plant at Aberthaw, which is the main facility of the Divestment Business in South Wales. These plants are located 50 to 60 kilometres away from each other.

(92) Respondents to the market investigation in the area reported that cement producers and importers are operating at high capacity utilisation rates due to an upturn in the construction business in the United Kingdom.45 One customer expressly indicated that the Notified Transaction will lead to less competition in South Wales.46

(93) For the reasons set out below, however, the Commission finds that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to grey cement in this catchment area.

(94) First, in the catchment area of 250 km around the Swansea plant, the combined market shares will be [20-30]% with an increment of [0-5]% and a significant constraint will be exerted by the Cauldon plant, which belongs to, and will be retained by, Lafarge. Currently the Cauldon plant supplies only small volumes into this area given that Lafarge supplies this area from Aberthaw. Post-transaction, Lafarge will not only have the capacity and ability but also the incentive to supply more volumes into the Swansea area from its Cauldon plant and compete with the Parties. Even if it is located further away than Aberthaw, the Cauldon plant [variable cost assessment] can […] sell cement into South Wales, including the Swansea area.

(95) This is supported by the availability of spare capacities at Cauldon. The plant currently operates at around [>50]% utilisation rate and has a spare capacity of […] kt, which is larger than the total capacity (throughput) of the Swansea terminal ([…]kt). Post-transaction, this spare capacity will increase to an estimated […]kt,47 because Cauldon will no longer supply grey cement to the downstream Lafarge RMX operations which will be divested to CRH.48 While the […]kt figure may overstate the potential additional overcapacity resulting from the Notified Transaction,49 additional capacity will be freed up and LafargeHolcim will be able to use it to compete in South Wales as well as in other regions in the United Kingdom (in particular the London area in South-East England).

(96) Second, CRH will have the incentive to maintain active its Swansea terminal and to import cement from its Irish plant located in Platin. Currently, the Platin plant has a spare capacity of [>50]%.50 The Irish market in general is characterised by significant overcapacity and lower prices, whilst demand and prices in the United Kingdom in general and South Wales in particular are rising. Aside from the price differential for grey cement in the two countries, CRH also made recent investments […].

(97) Third, responses from customers to the market investigation are in line with these findings. With the one exception mentioned above, customers generally did not state that the Notified Transaction would have a negative impact on competition in the catchment area.51 Half of the customers in South Wales indicated that they have already considered Cauldon as a potential alternative source of supply of grey cement. A majority of customers also indicated they would consider Cauldon as an alternative source of grey cement should there be a price increase of 10% in South Wales52.

Scotland

(98) The Divestment Business has a significant presence in the 150km catchment area around Dunbar ([40-50]%). Two customers based in the catchment area and that responded to the market investigation suggested that the Notified Transaction may give rise to potential negative effects on their business.53

(99) For the reasons set out below, however, the Commission finds that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to grey cement in this catchment area.

(100) First, the market share increment brought by CRH's terminal in the area will be limited to [0-5]%.

(101) Second, post-transaction, a number of alternative suppliers of grey cement will remain active in Scotland. For instance, Cemex (import terminal of Leith, Edimbourg), HeidelbergCement (import terminal of Bellshill, Glasgow), LafargeHolcim (import terminal in Glasgow) have operations within the catchment area, whereas other importers sell cement within the catchment area through terminals situated in other locations, such as Durham and Stranraer.

(102) Third, other customers in the catchment area and that responded to the market investigation did not raise any concerns regarding the Notified Transaction.54

(103) Fourth, while the two customers that expressed concern about potential negative effects on their businesses would have to source grey cement further away from their operations in order to source it from other producers, they would still have alternative sources of supply within the reach of the catchment area, with both of them stating they have already asked for quotes from other competitors.55

5.1.4.Conclusion on grey cement

(104) For the reasons set out above, the Commission finds that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to grey cement in the relevant catchment areas in Slovakia/Poland, France/Belgium and in the United Kingdom.

5.2.RMX

5.2.1. Relevant product market definition

(105) RMX is concrete that is manufactured for delivery to a customer’s construction site in a freshly mixed and unhardened state. It is a mixture of grey cement (and/or other cementitious additives), aggregates (generally comprising sand and gravel, or crushed rock), and water. RMX can be manufactured at a central plant, from where it is transported and placed at site. Alternatively, although less frequently (and not by the Parties in the EEA), RMX material inputs can be transported separately in volumetric trucks and only mixed into RMX at the construction site.

5.2.1.1. Past decisional practice

(106) In past decisions, the Commission has consistently considered RMX as single, distinct product market.56

5.2.1.2.The Notifying Party's arguments

(107) The Notifying Party submits that all specifications of RMX should be considered to form part of the same relevant product because the same RMX plant can manufacture the full range of RMX specifications.

5.2.1.3. Conclusion on the relevant product market

(108) In line with past decisions and the submissions of the Notifying Party, the Commission considers that RMX constitutes a single distinct product market for the purposes of the Notified Transaction.

5.2.2. Relevant geographic market definition

(109) Once RMX has been mixed, it must be used within approximately one to two hours. Therefore, RMX suppliers generally compete in geographic markets within a narrow radius of local production sites.

(110) In past decisions, the Commission considered but left open a radius of 15-40 km around a production site.57 In its most recent decision, the Commission considered that the appropriate geographic market over which RMX needs to be assessed is a radius of 25 km.58

(111) As the assessment of the Notified Transaction does not raise serious doubts as to its compatibility with the internal market under any plausible geographic market definition, the exact geographic market definition can be left open in this case.

5.2.3.Competitive assessment

(112) Although CRH and the Divestment Business are both active in the United Kingdom, their sites do not overlap at catchment area level. As regards Hungary, there is an overlap in the Parties' activities at catchment area level in three sites, but the Notified Transaction does not result in any affected market (combined market shares below 20%).59

5.2.4.Conclusion on RMX

(113) In line with the above, given that no affected markets arise in RMX, the Commission finds that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to RMX.

5.3. Alternative cementitious materials

5.3.1. Relevant product market definition

(114) Alternative cementitious materials refer mainly to slag and fly ash, both of which are by-products of other industrial processes. Slag is a by-product of a production of iron. It is obtained from blast furnaces along with molten iron. Fly ash, on the other hand, is a by-product of electricity generation resulting from the burning of powdered coal at high temperatures. They can be used in the production of cement and concrete to provide the end product with specific characteristics or to substitute clinker with less expensive raw materials.

(115) While fly ash does not require any further processing, liquid slag is granulated to produce granulated blast-furnace slag ('GBS'60). GBS exhibits cementitious properties and is used as hydraulic binder in the production of, for instance, cement, concrete, mortar and grout. GBS can be further ground to produce ground granulated blast-furnace slag ('GGBS'61). GGBS is then blended with ground clinker and other cement constituents to produce blended cements.

5.3.1.1. Past decisional practice

(116) In past decisions,62 the Commission considered, but ultimately left open, the question of whether products derived from fly ash and blast furnace slag belong to the same product market, referring to alternative cementitious materials as 'cement additives'.

5.3.1.2. The Notifying Party's arguments

(117) The Notifying Party submits that there is a single product market comprising slag (including GBS and GGBS) and fly ash since these materials can be used, to an appreciable extent, as substitutes for one another and for various other materials.

5.3.1.3. Conclusion on the relevant product market

(118) The exact product market definition concerning alternative cementitious materials can be left open as the competitive assessment remains the same under any plausible market definition.

5.3.2. Relevant geographic market definition

5.3.2.1. Past decisional practice

(119) In Heidelberg/Hanson, which concerned the United Kingdom, the geographic market definition was ultimately left open, although respondents to the market investigation supported a wider than national market.63 The geographic market definition was also left open in CSN/Cimpor.64 In the earlier case of CRH/Semapa/Secil JV, however, the wider market for cement additives was considered to be national in scope.65

(120) In Holcim/Cemex West, the Commission analysed the concentration based on 250 km radii around GBS sourcing sites in Germany, but left the exact geographic definition concerning GBS and GGBS open.66

(121) In Holcim/Lafarge, while the Commission assessed the concentration on both a national basis and on the basis of 250 km radii around source sites, it ultimately left open the exact geographic definition concerning alternative cementitious materials.67

5.3.2.2.The Notifying Party's arguments

(122) The Notifying Party submits that the geographic market for slag and fly ash is EEA-wide as alternative cementitious materials are commodities that can be transported economically in bulk volume up to 500km by truck, and beyond by train and/or barge. It further submits that there are substantial trade flows between EEA countries, given that (i) the materials are not produced in all Member States – the materials are transported from the steel and electricity producers production sites to the locations of consumption at the cement producers' sites, and (ii) consumption levels vary depending on the volume of cement and concrete production – alternative cementitious materials therefore flow in the direction of consumption.

(123) According to the Notifying Party, the conclusion on the scope of the relevant geographic market being EEA-wide will equally apply to GBS/GGBS and fly ash if treated as separate markets.

5.3.2.3. Conclusion on the relevant geographic markets

(124) The exact geographic market definition concerning alternative cementitious materials can be left open as the competitive assessment remains the same under any plausible market definition.

5.3.3.Competitive assessment

(125) The Parties' activities overlap in the sourcing of alternative cementitious materials from steel producers and fly ash from power plants operators. CRH does not sell alternative cementitious materials to third parties, except for in Belgium and the Netherlands. The Divestment Business sells alternative cementitious materials to third parties only in Great Britain.

(126) The methodology used for the Parties' market share assessment is based on procurement shares rather than sales shares. For the market share assessment, the Notifying Party has first estimated aggregated production volumes of alternative cementitious materials for all production sites in the EEA of which they are aware. In many instances, the Notifying Party was aware of the general scale of production volumes following discussions with producers in the context of tender procedures and annual forecasts. For steel, the Notifying Party has considered steel output and drawn conclusions from that on the likely output of slag. Where the output of steel/slag is unknown, the Notifying Party has taken the average output of a steel plant. For fly ash, average production per site is estimated based on the total hard coal fired power generation capacity per country, and the number of hard coal fired power plants. The Notifying Party has estimated the total market volume of slag and fly ash available from steel plants and power plants in the EEA to be 51,044,100t.68

(127) At EEA level, the combined procurement shares will be [10-20]% with an increment of [0-5]% in the EEA.

(128) At a national level, the Parties' procurement activities with respect to slag and fly ash overlap at national level only in Germany and in Spain. The Parties' combined procurement shares are below [5-10]% in Germany and below [0-5]% in Spain.

(129) When using a radius approach of 250 km around potential sourcing plants for alternative cementitious materials (inclusive of GBS, GGBS and fly ash), the Parties' activities overlap in numerous sites, located in 10 countries, namely Austria, Belgium, Netherlands, France, Czech Republic, Germany, Hungary, Poland, Slovakia and Spain.

(130) There is, however, only one site where the Parties' combined procurement share would result in an affected market. This site is located in Le Havre (France). The combined procurement share around this sourcing site will amount to [20-30]% with an increment of [0-5]%. This increment is not capable of affecting the market structure or the competition conditions in the affected catchment area.

5.3.4.Conclusion on alternative cementitious materials

(131) For the reasons set out above, the Commission finds that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to cementitious materials irrespective of whether the market is considered at EEA level, at national level or at catchment area level.

5.4. Aggregates

5.4.1. Relevant product market definition

(132) Aggregates are used as base materials in the construction of roads, buildings and other infrastructure, as well as raw materials used to make products such as concrete, asphalt and mortar. They may be: (i) quarried from land and dredged from the sea (together, “primary aggregates”); (ii) obtained from the waste products of other mining or industrial activities (“secondary aggregates”); or (iii) obtained from recycled sources such as demolition sites and construction waste (“recycled aggregates”). They are typically used in construction. They are also supplied for specialist uses such as railway ballast.69

5.4.1.1. Past decisional practice

(133) In past decisions, the Commission has considered aggregates as a single, separate product market.70 The Commission has also considered, but ultimately left open, a further segmentation between: (i) primary aggregates (crushed rock, gravel and sand); and (ii) secondary / recycled aggregates (such as colliery and china clay waste, slate, power station ash, slags and demolition/construction waste).71

(134) The UK Competition Commission has also defined one product market for these types of aggregates in its market investigation into the United Kingdom building materials markets, in particular for reasons of demand-side substitutability.72 In an earlier merger decision, the Competition Commission defined a separate product market for primary aggregates.73

(135) Within the primary aggregates category, the Commission has also considered, but ultimately left open, in past decisions, a further distinction between: (i) sand and gravel; and (ii) crushed rock.74

5.4.1.2. The Notifying Party's arguments

(136) The Notifying Party submits that construction aggregates generally constitute a single product market. It refers to the UK Competition Commission's report75 which found that primary and secondary construction aggregates form part of the same products market.76

(137) Moreover, the Notifying Party points to a steady growth in the use of recycled and secondary aggregates due to more efficient recycling technologies, various government initiatives and changes in product specifications that will allow for greater use of secondary or recycled aggregates as substitutes for primary aggregates.77

(138) In any event, the Notifying Party submits that the precise product market definition for aggregates can be left open as the Notified Transaction does not give rise to serious doubts irrespective of the precise delineation of the relevant product market.

5.4.1.3. Conclusion on the relevant product market

(139) For the purpose of the assessment of the Notified Transaction, the exact market definition can be left open as the competitive assessment remains the same under any plausible market definition.

5.4.2. Relevant geographic market definition

5.4.2.1.Past decisional practice

(140) In past decisions, the Commission has considered the aggregates market to be local/regional78 or at most national79 in scope and has retained a radius of 50 to 80km depending on the particularities of the areas concerned.80 This is due to the fact that aggregates are heavy and voluminous products with significant transport costs.

5.4.2.2.The Notifying Party's arguments

(141) The Notifying Party submits that the application of the 50km radius is the most appropriate geographic market in this case, principally because of the impact of transportation costs in the aggregates industry. It further submits that, due to large transport costs, it is more economically effective for aggregates players to set up new quarries every 30-50km as opposed to transport materials beyond that distance.

5.4.2.3. Conclusion on the relevant geographic markets

(142) In light of past decisional practice and the Notifying Party’s arguments, the Commission considers that assessing the local construction aggregates markets within a radius of 50-80km is appropriate in this case.

5.4.3. Competitive assessment

5.4.3.1. Overview of the activities of CRH and the Divestment Business

(143) CRH operates aggregates quarries in 5 EEA countries: Ireland, the Netherlands, Poland, Slovakia and the United Kingdom. CRH is primarily active in the production and sale of land-won primary aggregates (i.e. crushed rocks, sand and gravels) with some activity in lake dredging and recycling. CRH's activities in secondary and recycled aggregates are limited and carried out mainly in Ireland. With regard to specialist aggregates, CRH sells rail ballast in Ireland, the United Kingdom (Northern Ireland), Switzerland, Finland and Poland.

(144) The Divestment Business operates aggregates quarries in 4 countries of the EEA: France (mainland and La Réunion), Romania, Slovakia and the United Kingdom. The Divestment Business includes Lafarge's activities in rail ballast and high PSV in the United Kingdom.

(145) Aggregates quarries of CRH and of the Divestment Business overlap at catchment area level both in Slovakia and in the United Kingdom (Northern Ireland). In addition, the Notifying Party explains that there are three affected quarries in Ireland due to cross-border overlap between Ireland (CRH) and Northern Ireland (the Divestment Business).

5.4.3.2. Methodology for the calculation of market shares

(146) The competitive assessment for the regional markets is carried out on the basis of the plant/quarry-centred approach.81 Production shares serving as proxy for market shares are calculated on the basis of: (i) an estimation of aggregates sales into catchment area and (ii) an estimation of local aggregates demand. The consideration of both sales and demand side data leads to more precise estimation of production shares.

(147) Regarding the estimation of aggregates sales into catchment areas, quarry's production figures are used as a proxy for a quarry's sales into a catchment area. The analysis assumes that production is sold uniformly in a radius of 50 km around the quarry's location. The sales of overlapping quarries are attributed to a catchment area based on the percentage overlap it has with its own catchment area.

(148) The estimation of local aggregates demand is calculated by breaking down national aggregates consumption and calculating per-capita consumption. The NASA population dataset is then used to estimate the population around each plant. Local demand is calculated by multiplying the NASA local population by the national per-capita consumption.82

5.4.3.3. United Kingdom (Northern Ireland) and Ireland

(149) CRH is active on the aggregates market in Northern Ireland where it operates […] quarries. CRH's production shares in Northern Ireland amounted to [10-20]% in 2013. This presence in Northern Ireland is more diluted in the overall United Kingdom where CRH had a [0-5]% production share in 2013.

(150) The Divestment Business operates 212 quarries in the United Kingdom. While it has a more significant position than CRH in the United Kingdom, with a [20-30]% production share for aggregates in 2013, this share drops to [5-10]% when only considering Northern Ireland.

Table 10 - Aggregates production shares in overlap countries for 2013

| CRH (%) | Divestment Business (%) | Combined (%) |

United Kingdom | [0-5] | [20-30] | [20-30] |

Northern Ireland | [10-20] | [5-10] | [20-30] |

Source: Form CO, paragraph 381

(151) For the reasons set out in recitals (152) to (154), the Commission finds that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to aggregates in the relevant catchment areas in the United Kingdom (Northern Ireland) and in the cross-border region between Ireland and Northern Ireland.

(152) First, a majority of the Parties' overlapping quarries located in Northern Ireland and in Ireland will have combined production shares below 20%. In addition, there are ten affected catchment areas with combined market shares above 20%. The highest combined market shares would be Mullaghchrone in Ireland (combined production shares of [30-40]% with an increment of [0-5]%) and, Silica Sand in Ireland (combined production shares of [30-40]% with an increment of [0-5]%). Even for these areas, however, the increment in production shares brought about by the Notified Transaction will be marginal (comprised between [0-5] and [0-5]%) and unlikely to bring about any material change to the market structure.

(153) Second, post-transaction there will remain a number of competitors with the capability and incentive to increase output should the Notifying Party decide to increase prices. These include Lagan Group, FP McCann Ltd, CES Quarry products, Norman Emerson Group, WJ McCormick & Sons Ltd. and Gibson Bros Ltd.

(154) Third, regarding potential vertical competitive concerns, due to the limited increments and the resulting combined market, the Notified Transaction will not give the Notifying Party either the ability or incentive to foreclose actual or potential rivals’ access to supplies or customers.

5.4.3.4. Slovakia

(155) CRH is active on the aggregates market in Slovakia where it operates […] quarries. CRH's production shares in Slovakia amounted to [0-5]% in 2013.

(156) The Divestment Business operates 6 quarries in Slovakia. The Divestment Business has slightly bigger stronger position in Slovakia as it had a [0-5]% production shares for aggregates in 2013.

(157) The Commission finds that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to aggregates in the relevant catchment areas in Slovakia. This is because in the 8 overlapping catchment areas in Slovakia, estimated combined market shares will be between [5-10]% and [10-20]%, and increments between [0-5]% and [5-10]%.

5.4.4.Conclusion on aggregates

(158) In light of the above, the Commission finds that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to aggregates in the relevant catchment areas in the United Kingdom (Northern Ireland) and in Slovakia.

5.5. Asphalt and contract surfacing

5.5.1. Relevant product market definition

(159) Asphalt is manufactured by heating and mixing aggregates and a binding agent (normally bitumen), and is used for surfacing roads, car parks, footpath pavements, airport runways, and other sites. Asphalt mix is typically composed of 95% aggregates and 5% bitumen.

(160) Asphalt is typically purchased by private contractors engaged by public authorities in road construction and by those engaged in commercial and residential construction (such as surfacing around retail and housing developments). Given its perishable nature, asphalt is best laid within approximately two to three hours of dispatch.

(161) The works associated with the construction and maintenance of roads and other surfaces constitute contract surfacing (also known as contracting, asphalt surfacing, and road maintenance services).

5.5.1.1. Past decisional practice

(162) The Commission has assessed asphalt in several decisions and found that asphalt is a distinct product market from aggregates and road works.83

(163) In past decisions,84 the Commission has considered road construction to be a relevant product market in itself, distinct from the materials used, namely aggregates and asphalt.

5.5.1.2.The Notifying Party's arguments

(164) The Notifying Party agrees that asphalt constitutes a distinct product market, mentioning that this is also in line with a recent report of the UK Competition and Markets Authority (CMA).85

(165) The Notifying Party argues that contract surfacing constitutes a distinct relevant product market. In contract surfacing, asphalt is typically laid onto the prepared foundation layers of a road in layers, with each layer being compacted by paving machines to form the top surface of the road. The assets required to carry out contract surfacing activities are principally road planning and surfacing machines, paving machines, and offices.86

5.5.1.3. Conclusion on the relevant product market

(166) In light of past decisional practice and the Notifying Party's arguments the Commission considers that both asphalt and contract surfacing constitute distinct product markets.

5.5.2. Relevant geographic market definition

(167) Asphalt mix is a perishable product that needs to be transported in specially heated containers to prevent it from setting before it can be delivered and laid. This means that the asphalt mix needs to have a temperature of 150-190°C when arriving at the construction site.

(168) Regarding contract surfacing, the equipment required for road construction and maintenance is mobile and can be moved around a Member State to the point of demand.

5.5.2.1. Past decisional practice

(169) In past decisions, the Commission has considered a geographic market within a radius of 25-100 km from the asphalt plant.87 In Holcim / Lafarge, the Commission recently found that the geographic market for asphalt consists of radius of 40km around each asphalt facility.88

(170) As regards contract surfacing, the Commission has previously considered the market for road construction to be national, while leaving open the question of a more local segmentation.89

5.5.2.2. The Notifying Party's arguments

(171) While noting that the precise catchment areas might vary depending on a multiple of factors (such as topography, location of plants and demand density), the Notifying Party considers a distance of approximately 40km to be a good representative basis for defining local catchment areas in the United Kingdom.90 It also notes that this is in line with the extended catchment area recently used in a report by the CMA.91

(172) Consistent with the Commission’s view,92 the Notifying Party considers the geographic market for contract surfacing to be no wider than national.

5.5.2.3. Conclusion on the relevant geographic markets

(173) In light of past decisional practice and the Notifying Party's arguments, the Commission considers that the relevant geographic market for asphalt is a radius of 40km around each facility, while the relevant market for contract surfacing is national in scope.

5.5.3.Competitive assessment

5.5.3.1.Methodology for the calculation of market shares

(174) The competitive assessment for asphalt is carried out on the basis of the plant- centred approach. Production shares, serving as a proxy for sales shares, are calculated using two features: (i) an estimation of asphalt sales into catchment areas and (ii) an estimation of the local demand for asphalt. Regarding the estimation of asphalt sales into catchment areas, the analysis assumes that production is sold uniformly in a radius of 40 km around the plant's location.

(175) The estimation of local asphalt demand is calculated by breaking down regional asphalt consumption and calculating per-capita consumption at the regional level. The NASA population dataset is then used to estimate the population around each asphalt plant. Local demand is calculated by multiplying the local population around each plant with consumption per capita of the region in which the plant is located.93

(176) When calculating contract surfacing shares, the Notifying Party used two main approaches: (i) volume sales shares on the one hand and (ii) value sales shares on the other hand. The volume sales shares are calculated by dividing the Parties' sales in volumes by an estimate of the total asphalt production of construction materials and waste sectors experts.94 The value market shares are calculated by dividing the Parties' sales by value by the Parties' own estimate for the size of the contract surfacing market.

5.5.3.2.Overview of the Parties' activities

(177) CRH is active in producing asphalt in Ireland, the United Kingdom (Northern Ireland) and Poland.

(178) The Divestment Business is active in producing asphalt in the United Kingdom (Great Britain and Northern Ireland). It comprises 72 active asphalt facilities. Its main customers are local authorities, regional surfacing contractors and highway agencies. In 2013, the Divestment Business sold […] t of asphalt, generating sales of […] GDP.

(179) In contracting surfaces, the Divestment Business comprises 22 offices in the United Kingdom, with sales of […] in 2013.

5.5.3.3. United Kingdom (Northern Ireland) – Asphalt

(180) The Parties’ activities in asphalt overlap only in the United Kingdom (Northern Ireland).

(181) At a national level, the estimated combined market shares of the Parties in the United Kingdom will be [30-40]%, with an increment of [0-5]% from CRH.

(182) At catchment area level, all overlaps are in Northern Ireland, but they do not result in any affected market.

Table 11 - Asphalt catchment areas in Northern Ireland (2013)

Country | Site | Site owner | CRH | Divestment Business | Combined |

Northern Ireland | Craigantlet | Divestment Business | [10-20] | [0-5] | [10-20] |

Northern Ireland | Ballymena | CRH | [10-20] | [0-5] | [10-20] |

Northern Ireland | Croaghan | CRH | [20-30] | [0-5] | [20-30] |

Northern Ireland | Mallusk | CRH | [10-20] | [0-5] | [10-20] |

Northern Ireland | North Down | CRH | [10-20] | [0-5] | [10-20] |

Source: Form CO, paragraph 520

(183) For the reasons set out in recitals (184) and (185), the Commission finds that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to asphalt in the United Kingdom.

(184) First, at a national level, the Notified Transaction will result in a marginal increase, as CRH is a minor player with a market share of [0-5]%.

(185) Second, at catchment area level, the Notified Transaction will not result in any affected market, as the combined shares will in all cases be less than 20% with marginal increments below [0-5]%, and in the only area in Northern Ireland in which CRH has a market share exceeding 20% ([20-30]% in Croaghan) the Divestment Business is not active.

5.5.3.4. United Kingdom (Northern Ireland) – Contract surfacing

(186) The Parties’ activities in contract surfacing overlap only in the United Kingdom (Northern Ireland).

(187) For the reasons set out in recitals (188) and (189), the Commission finds that the Notified Transaction does not raise serious doubts as to its compatibility with the internal market in relation to contract surfacing in the United Kingdom.

(188) First, estimated combined volume and value market shares at national level in the United Kingdom amount to [10-20]% and [10-20]% respectively. Moreover, CRH is a minor player for contract surfacing in the United Kingdom and hence increments do not exceed [0-5]%.

(189) Second, the merged entity will face competition from several other players, including the new LafargeHolcim entity.

5.5.4. Conclusion on asphalt and contract surfacing

(190) For the reasons set out above, the Commission finds that the Notified Transaction does not give rise to serious doubts as to its compatibility with the internal market in relation to asphalt and contract surfacing in the United Kingdom.

6.CONCLUSION

(191) For the above reasons, the European Commission has decided not to oppose the notified operation and to declare it compatible with the internal market and with the EEA Agreement. This decision is adopted in application of Article 6(1)(b) of the Merger Regulation and Article 57 of the EEA Agreement.

1 OJ L 24, 29.1.2004, p. 1 ('the Merger Regulation'). With effect from 1 December 2009, the Treaty on the Functioning of the European Union ('TFEU') has introduced certain changes, such as the replacement of 'Community' by 'Union' and 'common market' by 'internal market'. The terminology of the TFEU will be used throughout this decision.

2 OJ L 1, 3.1.1994, p. 3 ("the EEA Agreement").

3 Form CO, paragraphs 59-67.

4 UK Competition Commission, 'Anglo American PLC and Lafarge S.A. A report on the anticipated construction materials joint venture between Anglo American PLC and Lafarge S.A.', 1 May 2012.

5 Commission communication in the framework of the implementation of Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 laying down harmonised conditions for the marketing of construction products and repealing Council Directive 89/106/EEC (Publication of titles and references of harmonised standards under Union harmonisation legislation), OJ C 259, 8 August 2014, page 1; see also http://standards.cen.eu/dyn/www/f?p=204:110:0::::FSPPROJECT:27250cs=13B3EDD735E572AF56B7EC3A4CA2E1AF6.

6 Case M.7252 – Holcim / Lafarge, 15 December 2014, recitals 16-18.

7 Cases M.7252 – Holcim / Lafarge, 15 December 2014, recital 19; M.7054 – Cemex/Holcim Assets, 9 September 2014, recital 37; M.6153 – Anglo American/Lafarge/JV, 16 May 2011, recital 25; M.4898 – Compagnie De Saint-Gobain/Maxit, 4 March 2008, recital 210.

8 Source: Case M.7009 – Holcim/Cemex West, 5 June 2014, recital 30.

9 The two-letter ISO codes (ISO 3166 alpha-2) are used as abbreviations for the relevant contracting parties to the EEA Agreement, except for Greece and the United Kingdom, for which the abbreviations EL and UK are used.

10 Cases M.7252 – Holcim /Lafarge, 15 December 2014, recital 49; M.7054 – Cemex /Holcim Assets, 9 September 2014, recital 39; M.7009 – Holcim/Cemex West, 5 June 2014, recitals 24 and 41; M.3713 – Holcim/Aggregate Industries, 14 March 2005, recital 7; M.3572 – Cemex/RMC,8 December 2004, recital 11; M.3415 – CRH/SEMAPA/Secil JV, 28 May 2004, recital 10; M.2317 a. Lafarge/Blue Circle (II), 1 March 2001, recital 9; M.1157 – Skanska/Scancem, 11 November 1998, recital 31.

11 Cases M.7252 – Holcim /Lafarge, 15 December 2014, recital 56; M.7054 – Cemex/Holcim Assets, 9 September 2014, recital 41; M.7009 – Holcim/Cemex West, 5 June 2014, recital 45.

12 Cases M.7252 – Holcim/Lafarge, 15 December 2014, recital 56; M.7054 – Cemex/Holcim Assets, 9 September 2014, recital 43; M.7009 – Holcim/Cemex West, 5 June 2014, recital 49.

13 See replies to question 8 – Questionnaire Q3 - Questionnaire to Customers – grey cement – United Kingdom, and replies to question 7 - Questionnaire Q5 - Questionnaire to Customers – grey cement a.France/Belgium.

14 See replies to question 8 - Questionnaire Q1 - Questionnaire to Competitors – grey cement – United Kingdom.

15 See replies to question 10 – Questionnaire Q1 Questionnaire to Competitors – grey cement – United Kingdom.

16 See replies to question 10 - Questionnaire Q3 - Questionnaire to Customers – grey cement – United Kingdom; and replies to question 8 - Questionnaire Q5 - Questionnaire to Customers – grey cement a.France/Belgium.