Commission, August 3, 2017, No M.8356

EUROPEAN COMMISSION

Judgment

WIETERSDORFER / AMIANTIT / HOBAS JV

Subject: Case M.8356 - Wietersdorfer / Amiantit / HOBAS JV Commission decision pursuant to Article 6(1)(b) of Council Regulation No 139/2004 (1) and Article 57 of the Agreement on the European Economic Area (2)

Dear Sir or Madam,

(1) On 29 June 2017, the Commission received notification of a proposed concentration pursuant to Article 4 of Council Regulation (EC) No 139/2004 by which the undertakings WIG Wietersdorfer Holding GmbH (‘WIG’, Austria) and Saudi Arabian Amiantit Company (‘Amiantit’, Saudi Arabia) acquire within the meaning of Article 3(1)(b) of the Merger Regulation joint control of Hobas Pipes International GmbH (‘Hobas Europe’, Austria). Amiantit will contribute its European piping systems business into Hobas Europe, currently a wholly owned subsidiary of WIG, and acquire 50% of its shares. WIG, Hobas Europe and Amiantit are collectively referred to as the ‘Parties’ or ‘Notifying Parties’.

1. THE PARTIES

(2) WIG is a group active in construction materials and in the manufacture and supply of pipes and pipe systems for different applications, based in Klagenfurt, Austria. WIG's subsidiary, Poloplast is active in the manufacture and sale of thermoplastic pipes.

(3) Hobas Europe is WIG's subsidiary active in the manufacture of fibre glass reinforced plastic (‘GRP’) pipes and pipe systems, based in Austria. Hobas Europe manufactures pipes of diameters between 150 – 3600 mm based on the centrifugal casting technology (3). It manufactures both circular and non-circular pipes.

(4) Amiantit is a diversified industrial group with global operations based in Saudi Arabia. Amiantit's core business activities comprise the manufacturing and sale of pipes and pipe systems, sale of pipe technologies and the manufacture and supply of polymer products.

(5) Amiantit's European subsidiaries ('Amiantit Europe') are active in the production and sale of GRP pipes and pipe systems in Europe. Amiantit Europe manufactures pipes of diameters between 25 and 4000 mm based on the filament winding technology (4). Amiantit manufactures both, circular and non-circular pipes.

2. THE CONCENTRATION

(6) WIG and Amiantit intend to merge their European activities in the manufacture and sale of GRP pipes and pipes systems under Hobas Europe, which they will jointly control after the Transaction. WIG's subsidiary active in the manufacture and sale of thermoplastic pipes is not going to be integrated into the joint venture.

(7) Amiantit will not have any other operations in Europe. WIG will not contribute its current plastic pipes business, Poloplast. Hobas Europe will be active in GRP pipes exclusively.

(8) The operation consists in Amiantit transferring the existing Amiantit Europe business to Hobas Europe and receiving in exchange shares in Hobas Europe, an existing subsidiary of WIG. As a result, both Parties will hold 50% of the shares in Hobas Europe.

(9) According to the Joint Venture Agreement, the Parties will both have an equal number of representatives on the Supervisory Board of the joint venture. Certain strategic issues, such as the approval of the budget, the mid-term business plan and the strategic plan require the unanimous vote of the Supervisory Board members. In case of disagreement, the issues are refferd back to the shareholders that will decide with qualified majority (75%) of the votes.

(10) Consequently, the joint venture will be jointly controlled by WIG and Amiantit.

(11) Therefore, the Transaction constitutes a concentration within the meaning of Article 3(1)(b) of the Merger Regulation.

3. EU DIMENSION

(12) The notified operation has been referred to the Commission pursuant to Article 4(5) of Council Regulation (EC) No 139/2004.

(13) The Transaction does not have Union dimension within the meaning of Article 1 of the Merger Regualtion as the turnover tresholds set therein are not met.

(14) However, on 1 February 2017, the Parties informed the Commission by means of reasoned submission that the notified operation was capable of being reviewed under the national competition laws of at least three Member States (namely, Austria, Germany, Poland and Slovenia) and requested it to be examined by the Commission.

(15) On 3 February 2017, the Commission transmitted this submission to all Member States. The Member States competent to examine the concentration did not express their disagreement to the request for referral within 15 working days.

(16) On 24 February 2017, the Commission informed the Parties that the notified operation was therefore deemed to have an EU dimension and was notifiable to the Commission.

4. COMPETITIVE ASSESSMENT

(17) The joint venture will unite the Parties' activities in the manufacture and sale of GRP pipes and pipe systems. GRP is one of a number of materials for the manufacture of pipes used in a number of applications.

(18) GRP is a composite material made of unsaturated polyester (UP) or vinyl ester (VE) resins, chopped and/or continuous glass fiber and minerals. UP and VE form part of one of the three types of plastics which are produced by the petrochemical industry: thermoplastics, thermosets and elastomers. Polyethylene (PE), polypropylene (PP) and polyvinylchloride (PVC) are thermoplastics. UP, VE and EP resins are thermosets.

(19) Although plastic is the major component of the pipe and fitting in terms of weight and more so in terms of cost, thermoplastics and thermosets have different characteristics. Thermosets are resistant to heat and chemicals, while thermoplastics melt and bend easily.

(20) GRP pipes can be manufactured through two production processes: centrifugal casting or filament winding. Each of these process, through production lines, allow for the production of pipes of all diameters, which may be used for any application. The computer-controlled parameters allow to tailor the pipe to the project for which they are manufactured and to vary the percentage of glass fiber and other ingredients within the produced pipe. The higher the pressure resistance required, the greater the glass fiber proportion within the pipe.

(21) Hobas Europe produces its pipes based on the centrifugal casting, Amiantit on the filament winding process.

(22) GRP pipes are used in several civil as well as industrial applications, notably sewage, drainage, irrigation, water supply, power plants and other industrial areas, such as the petrochemical industry or cable ducting.

(23) The joint venture will manufacture pipes and pipe systems that can be used in various infrastructure and industrial applications. However, the Parties' main focus so far has been on sewage and drainage pipes, which account for close to 80% of Hobas Europe's revenues and more than 50% of Amiantit's (5). These are also the applications that market participants indicated (6) as the ones where the Parties overlap.

4.1. Product market definition

4.1.1. Commission precedents

(24) The Commission has considered the markets for pipes and pipe systems in a number of precedents.

(25) In a case concerning two PVC pipe and pipe system manufacturers, the Commission considered that there could be a segmentation of the pipe market based on applications (water, gas, sewage, drainage, cable-ducting, irrigation), but ultimately left the exact product market definition open (7).

(26) Another decision of the Commission concerning plastic pipes considered the relevant product markets on the basis of specific applications, citing water pressure, gas pressure, sewage, drainage, electro protection and irrigation. (8)

(27) The distinction based on applications was also investigated in a case concerning plastic pipes and pipe systems. In that case, the Commission's investigation pointed to different competitive conditions across groups of applications (9) and drew a distinction between ‘non-pressure’ or ‘gravity’ applications such as drainage, and ‘pressure’ applications, such as domestic hot and cold water pipes, water/gas utility pipes or pipes for industrial applications. Substitution was found to be either uneconomical or technically impossible, while the regulatory environment was found to be different for many applications, as there exist, for instance, special rules for pipes carrying potable water or special plumbing codes.

(28) As regards sewage more specifically, the Commission had previously found (10) that pipes for sewage applications constituted a separate product market. In the same case, the Commission concluded that the relevant market consisted of all sewage pipes without a further sub-segmentation by materials, as the Commission found that different materials, such as clay, concrete and plastic, were largely substitutable, irrespective of the diameter required. (11) The consideration of all material within the same relevant market was also the Commission's position in a precedent concerning more specifically sewage pipes of below 400 mm of normal duty conditions. (12)

(29) As far as segmentation by material is concerned, in a precedent the Commission considered that there could be a potential segmentation between plastic pipe systems and non-plastic pipe-systems, but ultimately left the exact product market definition open. (13)

4.1.2. Distinction by application

4.1.2.1. The Notifying Party's views

(30) The Parties submit that the relevant product markets for the assessment of the present transaction are the market for the production and sale of pressure pipes and pipe system, potentially subdivided per application, into (i) raw water/irrigation pipes and pipe systems; (ii) potable water pipes and pipe systems; (iii) industrial pipes and pipe systems and (iv) other pressure pipes and pipe systems; and the market for the production and sale of non-pressure (gravity) pipes and pipes systems, potentially subdivided per application, into (i) sewage pipes and pipe systems; (ii) drainage pipes and pipe systems and (iii) cable ducting/electro pipes and pipe systems.

(31) Beyond the latter, the Notifying Party differentiates micro-tunnelling, which is a different, trenchless way of pipe laying: This way, the soil is not opened completely but only a shaft is dug from which a machine is lowered that bores a tunnel underground. The pipes are then lowered through the shaft and pushed into the newly created tunnel. Micro-tunnelling may be used for any application (sewage, drainage, irrigation, raw water, etc.').

(32) While from the supply side perspective technology (equipment and know how) and the production process used for pressure and non-pressures pipes are essentially the same, the Parties argue that, from the demand side, they serve different customer needs. The Parties add that the design and material composition differ for pressure and non-pressure pipes. Moreover, there are within each Party's organization sales teams dedicated to either pressure or non- pressure pipes and pipe systems.

(33) The Parties submit that also third party market research reports analyse the markets by distinguishing between applications. (14)

(34) Furthermore, the Parties argue that, from a regulatory perspective, national standard and technical notices concerning pipes usually also distinguish by application. (15)

4.1.2.2. The Commission's assessment

(35) In line with precedents, the Commission finds, on the basis of its market investigation, that there are a number of demand-side considerations pointing to a sub-division of pipes and pipe systems markets by application.

(36) The requirements concerning pipes used in different applications differ in terms of size, resistance to pressure, corrosion properties etc. and consequently, the range of choice between pipe types, diameters and materials is different. (16) For instance, pressure applications tend to have smaller diameters and clay and concrete are never used, which are on the other hand the most favoured materials for sewage applications. GRP is not suitable for very high pressure applications (e.g. 100-300 bars) (17), where ductal iron or steel is preferred. (18) The latter is the favoured material for potable water applications. Most plastic pipes are used in sewage and potable water. Metal pipes of various types are widespread in industrial applications. (19)

(37) Third party industry reports indeed analyse the pipe market per application, differentiating similar segments, such as underground drainage and sewage, soil and waste, roof/road/land drainage and cable protection (20), and sewage, potable water, construction, oil and gas, industry. (21)

(38) Not all competitors are active across the different set of pipe applications. Moreover, certain responding competitors identify alternative suppliers depending on the suitability of their products to target a specific need of the customer, which can be defined by an application. For instance, one alternative manufacturer of GRP pipes identified the Parties as competitors in ‘underground’ applications mostly. (22)

(39) This corresponds to the views of customers responding to the market investigation which, when asked to identify competitors of Hobas Europe and Amiantit, they listed different sets of competitors depending on the application. (23) Therefore, pipe suppliers seem to specialise or focus on certain applications.

(40) The different applications identified in past Commission decision thus constitute an appropriate sub-division of the market in order to capture, from a demand-side perspective, the areas of competitive interaction within pipes and pipe systems markets.

(41) With regard to sewage applications in particular, however, a number of respondents to the Commission market investigation indicated that it is necessary to further distinguish, within sewage pipes and pipe systems, those solutions that are suitable for sewage relining.

(42) Sewage relining is a technique to renovate existing sewage pipes in a trenchless process that is without the need to open the ground. Sewage systems in European cities are partly over hundred years old and in need of continuous rehabilitation, which makes sewage relining an important application next to new sewage pipe laying, as it offers a faster and more cost efficient alternative. Some market participants pointed (24) at the Parties being strong in sewage relining.

(43) The Commission therefore finds it appropriate to segment the pipes market according to a distinction by application, and distinguish in particular sewage application with a sub-segment for sewage relining, drainage, irrigation, water supply (potable water), hydro-power and micro-tunnelling.

4.1.3. Distinction by diameter

4.1.3.1. The Notifying Party's views

(44) The Parties submit that the market for pipes should not be further segmented on the basis of pipe diameter as all pipe manufacturers are able to manufacture pipes of all sizes.

(45) The Notifying Party adds that the interpretation of large and small diameter is also very fluid and depends on the application; for instance, for the micro- tunnelling segment, only pipes above 1000mm diameter are considered to be large, while in the hydro-power large pipes would have a diameter of 800mm or more.

(46) However, the Notifying Party agrees that for the non-pressure applications, which are also the largest, (sewage, drainage and sewage relining) a possible cut-off between small and large diameter pipes could be established at 400mm. The Notifying Party submits that for industrial applications and pressure applications (e.g. water supply) the breakdown is more uncertain.

4.1.3.2. The Commission's assessment

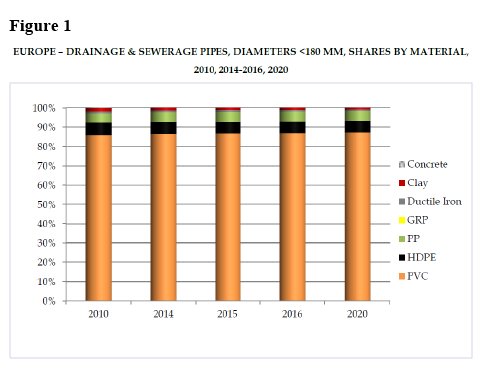

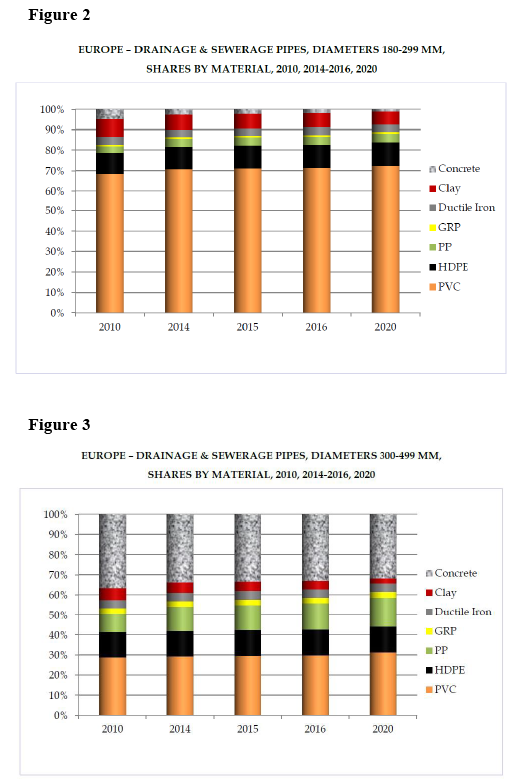

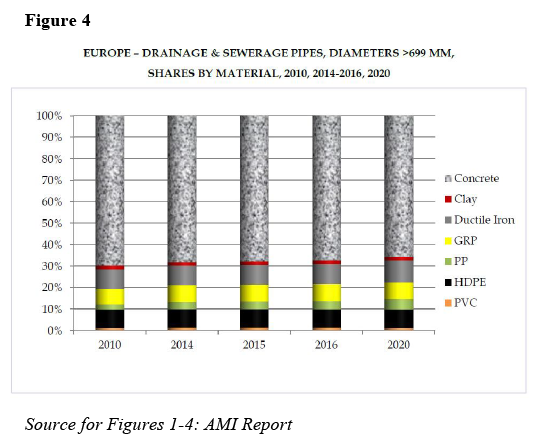

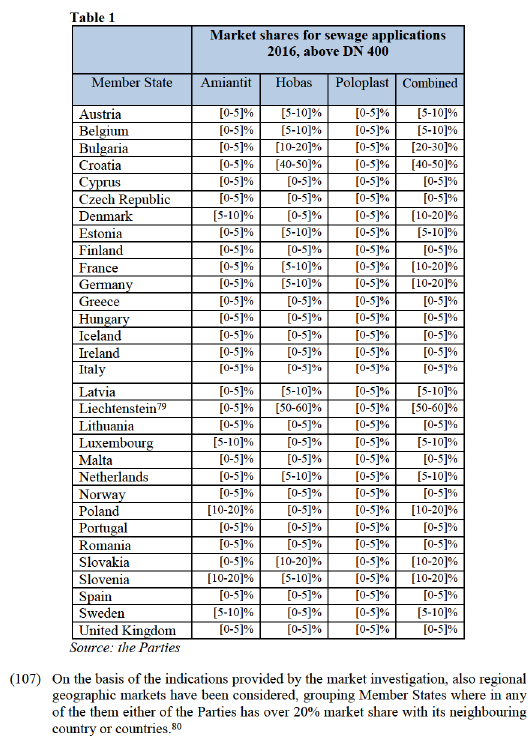

(47) Within the market investigation, a number of elements pointed at potential non homogeneous conditions of competition based on the diameter of pipes. This is mainly due to the fact that the range of suitable materials for pipes may change according to the diameter of the pipe. (25) See, for example, Figures 1-4 below.

(48) In smaller diameters (up to 400/500 mm), plastics/thermoplastics is the materials predominantly used. Respondents to the market investigation indicated this is mainly due to its price competitiveness. (26) In larger diameters, plastics are less and less used, which an industry report contends, it's not because of technical but more because of commercial attributes. (27) Above 400/500mm and as diameters increase, more and more concrete and steel reinforced concrete is used. GRP is suitable for small as well as large diameters, but most commonly it is used in the large diameters (above 400/500 mm) (28). This is further evidenced by the Parties' sales figures, showing that ca. 85% of their revenues are achieved in the above 400/500 mm segment. It has to be noted, however, that in case of sewage and drainage pipes, which are the applications where the largest diameter pipes are used, ca. 95% of the market is pipes below the diameter of 500mm. (29)

(49) The typical diameters that are used in the specific applications also differ. For pressure applications, such as water supply, smaller diameters, even below 150 mm are prevalent. For gravity applications on the other hand, such as sewage and drainage, the required diameters range into the highest segments, even 3000mm and above. For microtunneling, the mid- to large diameters are typical, between 400 and 1500 mm as reported by most respondents. (30)

(50) Evidence from the market investigation also suggests that with growing diameter of a pipe the range of suitable materials decreases. (31) Customers noted a wide choice of materials in the lower diameters for each application. Above 1500mm, only ductal iron, steel, concrete and polymer concrete figure next to GRP, above 2000mm only steel, concrete and polymer concrete, above 3000mm it is only concrete, according to the feedback received from market participants.

(51) The strength of the Parties' GRP offering lies mainly in pipes of a large diameter. This is confirmed not only by respondents to the market investigation, but also by the Parties' internal documents. (32)

(52) The indication that the Parties' strength lies in particular in pipes of large diameters was also raised by a GRP competitor who pointed at potential competitive concerns from the transaction, (33) referring in particular to pipes larger than 400/500mm. While it is difficult to establish a specific diameter beyond which conditions of competition change, as a 400mm was indicated (34) as a relevant diameter beyond which the Parties would hold particular strength, the Commission also assessed separately pipes larger and smaller than a diameter of 400mm.

(53) In conclusion, the Commission finds that, for the purpose of the present Transaction, the exact market definition as to a distinction between small and large pipes, taking as a cut-off a diameter of 400mm, can be left open, as the transaction does not raise serious doubts even when assessing these segments separately.

4.1.4. Distinction by material

4.1.4.1. The Notifying Party's views

(54) The Notifying Party contends that pipes markets should not be further segmented by materials as pipes made of different materials are interchangeable. In the Notifying Party's view, there are no substantial differences between materials with regard to technical and physical properties, and in general customers do not have preferences for any material. The Parties argue that customers' choice is based on price, not on material, and thus different materials compete for the same applications. Therefore the Notifying Party claims that pipes of different materials can be equally adequate substitutes from a demand-side perspective.

(55) As regards GRP in particular, the Parties explain that it has a number of qualities. It is a lighter material than concrete or steel, which allows for easier transportation and installation; it is resistant to corrosion, which makes it durable and suitable for chemically aggressive environments; it is flexible but resistant, withstanding pressure even in large diameters. It can be manufactured in long pieces, reducing the number of fittings and joints required.

(56) Notwithstanding these characteristics, the Parties submit that GRP competes with several other materials, and it is still not as widespread as other materials. The Parties observe, in particular, that according to industry statistics, GRP is generally the material of choice in only 2 to 4% of new pipe installations. The Parties specialise in sewage, drainage and water supply, where they claim customers are public institutions, which are conservative in trying materials with shorter track records than more commonly used materials such as clay, steel or concrete.

4.1.4.2. The Commission's assessment

(57) The Commission preliminarily observes that, from a demand-side perspective, the segmentation of the pipes and pipes systems markets according to the application and size of the pipe addresses is capable of capturing the competitive interactions between materials that can in principle be used for the given application in view of the size of the pipes needed by the customer. In particular, because different materials can be suitable depending on size and application, the purpose of the market segmentations previously identified by the Commission is to make sense of the different conditions of competitions across applications and sizes mainly resulting from the different selection of materials available.

(58) However, in view of the fact that both Parties are active in the manufacture of pipes of the same material, despite the different technologies used, and in light of concerns of some market participants that conditions of competition for GRP would materially differ (35), the Commission has investigated whether, within the narrow market defined by an application and size, GRP should by itself constitute a separate narrower market.

(59) From a supply side perspective, manufacturers of pipes are usually active in one or at most two materials, as raw materials, production processes, equipment and know how differ for each material. (36) As regards GRP specifically, some manufacturers are also active in thermoplastics at the same time.

(60) However, on the basis of responses to the market investigation, industry sources, the Parties' internal documents and other available information, the Commission finds that from a demand-side perspective other materials can be suitable substitutes to GRP although these vary across applications and sizes.

(61) First, the Parties provided information from public sources regarding municipal calls for tenders, through which civil infrastructure pipes are usually procured. The Parties argue that in these calls for tenders the material of the pipes is mostly not specified, therefore all materials can compete for the projects. If the call nevertheless specifies a material, it is only rare cases GRP.

(62) In this regard, the Parties analyse municipal calls for tenders issued in the first five months of 2017 in the countries where the activities of the businesses contributed into the joint venture mainly overlap (Austria, France, Germany and Poland). In France, from 100 examined tenders 50 allowed competition from all materials, while only five mentioned GRP and one explicitly requested it. (37) In Germany, 220 tenders were collected, from which 93 were open, 95 contained a preferred material, leaving competition from other materials however open. From the latter, five mentioned GRP. In Poland, from 26 tenders 17 were found to be open and 9 mentioned GRP leaving competition from other materials open. In Austria, 60 tenders were reviewed, with 29 open, (37) with a preferred material, allowing for other materials and eight were closed. Only one designated GRP from this eight.

(63) Market participants have confirmed that the market for pipes and pipe systems is tender-driven, and that, in most tenders, specifications do not mention materials but rather the required functions and properties. (38) A large competitor remarks for instance, when talking about tenders: 'Compared to the general Pipes demand, GRP-Pipes are very seldomly requested' (39).

(64) Second, from a regulatory perspective, technical standards for GRP pipes do not differ from standards from certain other materials.

(65) In particular, technical specifications by the international ISO and the European CEN, the two technical standardisation organisations, both classify GRP pipes alongside other types of plastic pipes. (40)

(66) Moreover, standards elaborated at national level and submitted by the Parties, which are application specific, (41) such as British and French standards for sewage applications, list a wide array of commonly used materials for sewage construction, including for instance concrete, PP and PE pipes, next to GRP.

(67) Third, respondents to the market investigation provided indications that pipes of different materials are substitutable.

(68) Within customers, while some respondents pointed at superior features for GRP for large pipes, particularly for sewage and sewage relining applications, (42) other market participants generally indicated (43) a plurality of materials they can choose from as alternatives to GRP.

(69) In particular, for all applications where the Parties are active (sewage, sewage relining, drainage, irrigation, micro-tunnelling, hydro-power, and water supply) customers identified alternative materials in all diameters and applications, while materials considered suitable were not systematically the same for all applications. (44) As indicated by a certification body, for instance, 'GRP represents only 3-6% of the pipe market, which is mostly due to the availability of lower priced alternatives'. (45)

(70) As regards competitors, some competitors active in GRP pointed at the overlap of the Parties activities on GRP pipes. (46) One GRP competitor, in particular, suggested that the relevant product markets should distinguish pipes both by applications (sewers, sewer relining, drainage, irrigation, hydropower, water supply and micro-tunnelling) and at the same time also by materials (GRP pipes and pipes from other materials, including, for example, plastic, concrete and steel pipes). Furthermore, this competitor submits that large diameter GRP pipes that are used for certain applications, such as municipal projects for sewage or sewage relining, show limited substitutability with other materials, and that consequently, large diameter GRP pipes for each of these applications should constitute a separate product market.

(71) However, other GRP pipe manufacturers as well as companies active on in other materials confirmed that GRP has to compete for share against other materials. A competitor active in a different material, in particular, observed that 'For GRP to win market share against the concrete lobby is extremely difficult.' (47) Even competitors focussing on GRP recognise that the main strategic aim of GRP manufacturers in order to gain share, in line with Parties' arguments made by the Parties, is to enhance the image and acceptance of GRP as a material vis a vis other more widely-used materials. (48) As observed by a certification body, 'Engineers are familiar with mostly steel and concrete because those are considered “old” and trustworthy materials'. (49) As a large GRP competitor puts it ' The paradox between the excellent GRP-Pipe features and the very limited demand has two main reasons: a) purchasing traditions (see above under (8)) and b) there have been few major infrastructure (sewage) investments in Europe in the past 4-5 years.' (50)

(72) These responses are consistent with the fact that, within the market investigation, when customers identified (51) the Parties’ main competitors in the respective applications, they listed companies manufacturing pipes with a variety of materials, such as steel, concrete, reinforced concrete, PVC/PP/PE and in some cases GRP, depending on the application.

(73) Fourth, as to whether there are applications where GRP is the only suitable option, the majority of customers replied that there were no such applications. (52) Among the minority of customers that indicated that there were situations where GRP is the only option, they explained that while GRP can be the best option, this is mostly based on commercial considerations and that there are alternatives to GRP. (53) As a customer puts it ‘Mainly commercial reasons, tough pipes with an affordable price’.

(74) The fact that commercial considerations drive customer choices across different suitable materials was confirmed by the market investigation. Respondents to the market investigation indicated that, while theoretically there are several different applications and sizes in which GRP is a technically suitable material, the fact that it is mostly sold on certain applications where large sized pipes are required is explained by the fact that its comparative cost compared to other materials become competitive. (54) This also reflects the Parties' own strategic positioning efforts, as described in their internal documents. (55)

(75) On the other hand, the sensitivity of customers to the cost of different materials (which can be measured as cost of purchase or total cost of ownership) is also confirmed by feedback on how customers would react to price increases. In particular, asked how they would respond to a 5-10% price increase for GRP pipes, the majority of customers indicated that they would switch to another pipe material for some or all pipe applications. As one customer noted, 'Prices of different piping materials will be checked. If GRP will increase in the price, alternatives will be considered…'. (56) Other market participants, commenting on GRP pipes specifically, indicated that 'if their price level increased, nobody would use them any longer' (57) and 'sewage management companies will completely turn away from GRP if the prices get even higher'. (58)

(76) Fifth, as regards which materials compete with GRP, these are different depending on the applications considered.

(77) The vast majority of customers indicated that range of the most suitable materials for pipes include at least plastics/thermoplastics, GRP, concrete, steel reinforced concrete and steel.

(78) Plastic materials prevail in smaller diameters (up to 400mm), with plastics also seen generally as more similar to GRP among customers that answered that indicated they would switch to another material. (59)

(79) As regards larger diameters, aside from plastics, the suitable alternatives for GRP seem to vary depending on the application. For sewage, sewage relining (60) and drainage applications, for which GRP pipes are mostly sold by the Parties, the vast majority of customers indicated concrete, reinforced concrete or clay as suitable substitutes in the larger diameters (from 400 mm onwards). (61)

(80) Contrary to the above mentioned applications, when considering pressure applications, e.g. water supply, irrigation or hydropower, customers largely indicated steel as the main substitute to GRP. (62) ‘For potable water systems, GRP pipes are not the most common option, and normally steel and polyethylene pipes are preferred.’ (63)

(81) Sixth, the picture from the market investigation, of a market where different materials compete with GRP on any given applications is confirmed by the Parties' internal documents. In particular, while the Parties monitor different materials used for specific applications.

(82) Internal documents (64) of the Parties also show that strategic aims target improving the image and the acceptance of the material GRP vis a vis the other materials, especially concrete or steel, clearly indicating that the Parties consider GRP competing in the same market as concrete and other materials, depending on the application.

(83) In conclusion, the Commission finds that, in relevant markets consisting of a given application and size, GRP pipes compete in the same market as plastics and other materials, depending on the application. For the purposes of the assessment of the present transaction, the Commission considers that for large pipes in pressure applications, the relevant markets consists at least of pipes of GRP, plastics, and steel, whereas for large pipes in sewage, sewage relining and drainage, the relevant market consists at least of pipes of GRP, plastics and concrete. The question whether other materials compete with those identified can be left open, as the transaction would not raise serious doubts even if additional materials were included in the relevant market.

4.1.5. Distinction by shape

(84) Sewage pipes can also be segmented according to their shape, into circular pipes and non-circular pipes, such as egg-shaped or oval pipes. Such non-circular pipes are mostly used for the renovation of existing non-circular sewage pipes and for drainage pipes. Oval pipes have the property to increase the flow rates when water volumes are low, which makes them particularly suited for sewage applications, where the sewage should not stagnate.

4.1.5.1. The Notifying Party's views

(85) The Notifying Party argues that non-circular pipes as such should not constitute a separate product market; this is only one technique for sewage and drainage renovation. For the purposes of sewer rehabilitation, the Parties contend that there are equivalent substitutes, which would be (a) the use of concrete which is projected inside an existing pipe (so called ‘shotcrete’), (b) cured-in-place plastics (CIPP) where the contractors purchase the material directly and (c) GRP oval shaped pipes, where all three methods compete for rehabilitation/renovation projects.

(86) The Parties submit that this substitution is evidenced by both Amiantit and Hobas Europe having lost market share over the last l5 years to CIPP companies. As opposed to pre-cured pipes that the Parties produce, CIPP is a specific method to form a GRP pipe inside the existing pipe matching its internal dimensions and not requiring cementing and grouting. The Parties hold that traditional pre-cured GRP pipe manufacturers such as the Parties compete vigorously with cure-in-place solutions.

(87) The Parties add, that renovation of non-circular sewage pipes can also be done with circular pipes, whereby a dry weather gutter is formed at the bottom of pipe in order to improve flow characteristics.

(88) The Parties also add that shall non-circular pipes be differentiated; the market encompasses non-circular pipes made of other materials beyond GRP, which are thermoplastics, concrete and polymer concrete.

4.1.5.2. The Commission's assessment

(89) The market investigation indicated that non-circular pipes are less common than circular pipes, including for manufacturers of GRP pipes. The Parties achieve less than 10% of their combined turnover with non-circular pipes. In the estimate of a competitor, 'The egg shaped GRP pipes market for sewage applications represent a small fraction of the total GRP pipe market, ca. 2-3%' (65)

(90) Within the market investigation, one GRP competitor indicated that 'Hobas and Amiantit are the only significant suppliers within the EU that also produce oval and egg-shaped large diameter GRP pipes. These oval and egg-shaped pipes are particularly suited to specific applications, such as sewers and sewer relining.' (66) The same competitor estimates that, for those two applications, approximately 30% of all GRP pipe orders are for oval and egg-shaped large diameter GRP pipes.

(91) As regards the distinction between circular and non-circular pipes, the market investigation seemed to confirm that, while for sewer and sewer relining projects in particular circular and non-circular pipes are both used, non-circular pipes are used on projects where circular pipes are not as suitable a substitute.

(92) In particular, a majority of customers responding to the market investigation indicated that under certain circumstances, only non-circular pipes could be used for sewage and sewage relining. (67) This seems due mainly to technical reasons. (68) From a supply-side perspective, the manufacture of non-circular GRP pipes may also require a different production line, and fewer companies are reportedly able to offer pipes of a non-circular shape. (69)

(93) The market investigation indicated that the Parties and one smaller GRP manufacturer, Budaplast, were mainly the only suppliers of non-circular GRP pipes in the EEA. (70)

(94) The market investigation, however, did not support the view that, on applications requiring non-circular pipes GRP is the only suitable material. In particular, responding customers indicated that while on certain projects a non-circular pipe cannot be replaced by a circular pipe, non-circular pipes of different materials can be chosen. Materials indicated by customers include steel, clay, concrete, polymer concrete, thermoplastics and GRP. (71) This view was confirmed also by customers specialising in projects also requiring non-circular pipes. (72)

(95) Because non-circular pipes are manufactured and used for specific applications only, a further sub-segmentation by application is also not appropriate.

(96) In conclusion, the Commission finds that non-circular pipes, irrespective of a distinction by material, belong to a separate market than circular pipes.

4.2. Geographic market definition

4.2.1. Commission's precedents

(97) In its precedents, the Commission has not established a consolidated approach to the geographic scope of pipes markets. In two decisions, the Commission found that the geographic market for sewage pipes was EEA-wide. (73) However, the Commission had earlier found elements which suggested that the geographic market for pipes could be regional in scope, and although some elements pointed to narrower, national markets, it ultimately left the precise scope of the geographic market open (74). In a more recent precedent, the Commission found evidence that pricing and commercial strategy were decided at national level, but also ultimately left the precise market definition open. (75)

4.2.2. The Notifying Party's views

(98) The Parties submit that the geographic market for the production and sale of pipes and pipe systems is EEA-wide. The Parties consider that the conditions of competition are similar throughout the EEA; all major manufacturers offer the same products with the same conditions in any of the EU Member States and there are no barriers to trade at the European level.

(99) The Parties furthermore submit that a large part of their sales is achieved outside the country of production. As concerns Amiantit's plants in Poland, Spain and Germany, only 49%, 22% and 52% of their respective turnover is achieved in the country where the plant is located. From Amiantit's Spanish plants, even 34% of the production leaves the EEA. Hobas Europe manufactures in Austria, Germany, Poland and Romania, for which 28%, 39%, 38% and 6% of sales respectively are achieved in the latter countries.

4.2.3. The Commission's assessment

(100) Within the market investigation, market participants pointed at transport costs, as a factor limiting the distance to which pipes can be delivered to customers, particularly pipes of large diameter.

(101) A majority of respondents to the market investigation indicated that pipes manufacturers tend to supply their products on a wider geographic scale than the countries where their manufacturing facilities are located, and at least into neighbouring countries. The shares of sales, which pipe manufacturers responding to the market investigation achieved outside their country of production was in the majority of cases non insignificant, ranging between 20-30% on average. However, manufacturers also mentioned that the maximum distance they would be ready to ship their products depended on the material of the pipe (weight considerations) and on the diameters (volume considerations). (76)

(102) Against this background, however, some respondents also pointed at a number of elements pointing at narrower markets, such as national customer preferences (including language barriers) and different regulatory standards, such as different national certification requirements. (77) The majority of customers reported to purchase within their country or in the neighbouring countries. (78)

(103) Overall, while the investigation provided indications of a market of a regional scope, the Commission finds that, for the purposes of the assessment of the present transaction, the exact geographic market definition can be left open, as the Transaction does not raise competition concerns even under a narrower national geographic market definition.

4.3. Competitive assessment

(104) The Parties' activities overlap mainly in the supply of circular pipes for sewage, sewage relining, and drainage applications, as well as in non-circular pipes.

(105) The concentration does not lead to affected markets at an EEA level.

Sewage pipes

(106) As regards sewage pipes, in line with the narrowest market definition as described above, the Commission has assessed the effects of the transaction on large diameter sewage pipes of GRP, plastics and concrete at national level. Even under this narrow market definition, the transaction does not raise any affected market (See Table1).

(108) Affected markets only arise under the hypothetical regional markets consisting of Croatia (combined market share [40-50]% with no overlap) and Slovenia (combined market share [10-20]%) (81) The combined market shares of the Parties amount to [30-40]%.

(109) The Parties submits in this respect that the two countries should not be grouped together as they have different cultures, languages and clients, and they are served through two distinct sales offices and distribution channels within Hobas. The Parties also note that competitors they face in the two countries are different.

(110) The Parties note that there is a large number of competitors active in this segment for both countries, which are internally active companies, such as Pipelife, Purgarija, Wavin and a large number of local producers in Croatia, such as Vargon, Heplast-pipe, Krah, Vodoskok, Vodoplast and in Slovenia, such as Kp Plas, Sisteko, Stigma, Zagozen, ALPRO and PGM for plastic and concrete pipes.

(111) The market investigation has not indicated any concerns related to the Croatian and /or Slovenian market.

(112) As regards Member States where Hobas has over 30% market share and the other Party is not active, i.e. Croatia and Liechtenstein for sewage applications, the Parties submit that Amiantit [BUSINESS SECRET relating to current sales strategy of Amianti].

(113) The Commission considers that, although these markets could be regarded as technically affected in the meaning of Section 6.4 Form CO, serious doubts appear unlikely in light of the competitive structure of their neighbouring markets.

(114) As regards small diameter sewage pipes, as shown in Figure 1 to 4 above, the share of concrete pipes in very low. In any case, the Parties provide market share estimates on a narrower market containing GRP and plastics. Even under such a more conservative scenario the transaction does not result in affected markets on any national market, with highest market shares for sewage and sewage relining is Austria ([10-20]%).

(115) The concentration does not lead to affected markets for small diameter plastic and GRP pipes for sewage applications on a regional revel, under any alternative grouping of neighbouring countries.

(116) A competitor of the Parties expressed concerns (82) that the transaction would combine the largest suppliers of large diameter GRP pipes in Europe and eliminate all existing competition, with a dominant position for the supply of these pipes in a number of Member States (particularly Austria, Germany, France and Poland) and on a number of applications, including sewage, sewage relining, drainage, irrigation, water supply and micro-tunnelling. The arguments raised are similar across applications, and will thus only be discussed in this section.

(117) As discussed above in the section on market definition, the Commission considers that in order to assess the competitive constraints faced by GRP pipe manufacturers such as the Parties, the boundaries of the relevant market should also encompass pipes of other materials that can be used as substitutes for the applications and diameter ranges served by the Parties. The Commission thus considers it appropriate to consider the market shares provided in the table above as more representative of the effective position enjoyed by the Parties on the relevant market.

(118) The main arguments justifying the definition of a relevant market consisting not only of GRP pipes, which essentially confirm that the Parties would continue to face constraints post-transaction also from suppliers of other materials, were discussed in the section on product market definition. However, and despite the absence of affected markets, the Commission also investigated whether irrespective of the limited combined shares the transaction could lead to the creation of significant market power on any such market.

(119) First, the suitability of other materials than GRP, which are included in the relevant market, is not only described in the abstract by market participants, but also confirmed as a source of actual competitive interaction in sourcing events. On top of the tendering information described above at paragraph (62) , the majority of customers responding to the market investigation confirmed that at their last sourcing event they considered alternative materials to GRP. (83)

(120) Second, while some customers expressed concerns on competition between GRP manufacturers and the potential impact of the Transaction on GRP prices, most of them clarified in follow-up contacts (84) with the Commission that concerns often regarded aspects of product continuity and confirmed that other materials would be an alternative source of competition to the Parties. Two Austrian customers explain: '…GFK Rohre bieten technische Vorteile …Trotz allem wären Betonrohre eine Alternative‘, ‘Grundsätzlich können Betonrohre als Alternative zu GFK Rohren angesehen werden, auch für Rohre mit größerem Durchmesser als 400mm'. (85)

(121) Moreover, the majority (86) of responding customers did not expect or identify any impact of the proposed Transaction on their companies and on the pipe market.

(122) Third, aside from competitors active in the manufacture and supply of different materials, respondents to the market investigation identified other GRP manufacturers such as FPI, Superlit, Budaplast, Sarplast, FKT FAssbender or Vetroresina. (87) The expansion of smaller GRP producers in the EEA was also noted. (88)

(123) Fourth, some respondents to the market investigation also agree that, a price increase in GRP, aside from a switch to other materials, could also entail new entry of other GRP suppliers more likely, from other countries but also from outside of Europe. A customer explained for instance that if 'Preise steigen, Produktionsstätten in Österreich werden mehr und mehr ausgelagert, Lieferanten aus nicht EU-Länder werden an den Marktteilhaben wollen' (89)

(124) In conclusion, the Transaction does not raise serious doubts as to its compatibility with the internal market in any national market for sewage pipes.

Sewage relining

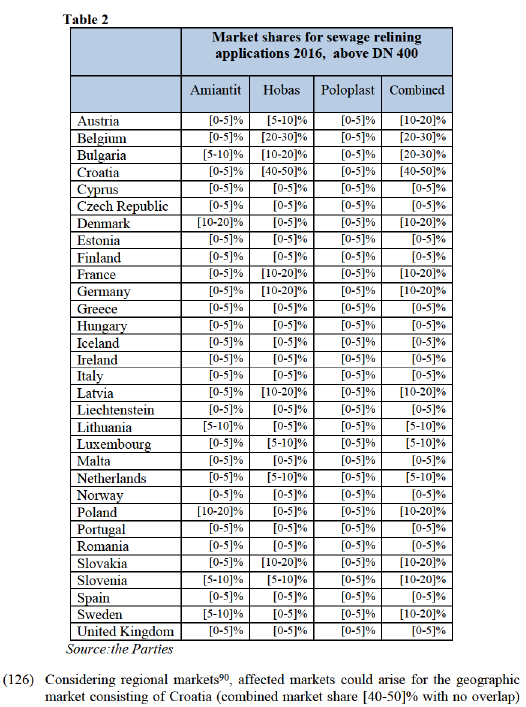

(125) As regards sewage relining, in line with the narrowest market definition as described above, the Commission has assessed the effects of the transaction on large diameter pipes for sewage relining of GRP, plastics and concrete at national level. Even under this narrow market definition, the transaction does not raise any affected market (See Table 2).

and Slovenia (combined market share [10-20]%). (91) The combined market shares of the Parties amount to [30-40]%.

(127) The Parties submit that the arguments in paras (109) and (110) as concerns the sewage market also apply in respect of sewage relining.

(128) The market investigation has not indicated any concerns related to the Croatian and /or Slovenian market.

(129) As regards Member States where Hobas has over 30% market share and the other Party is not active, i.e. Croatia for sewage relining, the Parties submit that Amiantit [BUSINESS SECRET relating to current sales strategy of Amiantit].

(130) The Commission considers that, although these markets could be regarded as technically affected in the meaning of Section 6.4 Form CO, serious doubts appear unlikely in light of the competitive structure of their neighbouring markets.

(131) As concerns sewage relining for small diameters including plastics and GRP, market shares are even lower than for large diameters, therefore, no affected markets arise on any of the national markets.

(132) The concentration does not lead to affected markets for small diameter plastic and GRP pipes for sewage relining applications on a regional revel, under any alternative grouping of neighbouring countries.

(133) As noted in para (116), the arguments described in paras (117) to (123) also apply to sewage relining.

(134) In conclusion, the Transaction does not raise serious doubts as to its compatibility with the internal market in any national market for pipes applied for sewage relining.

Drainage

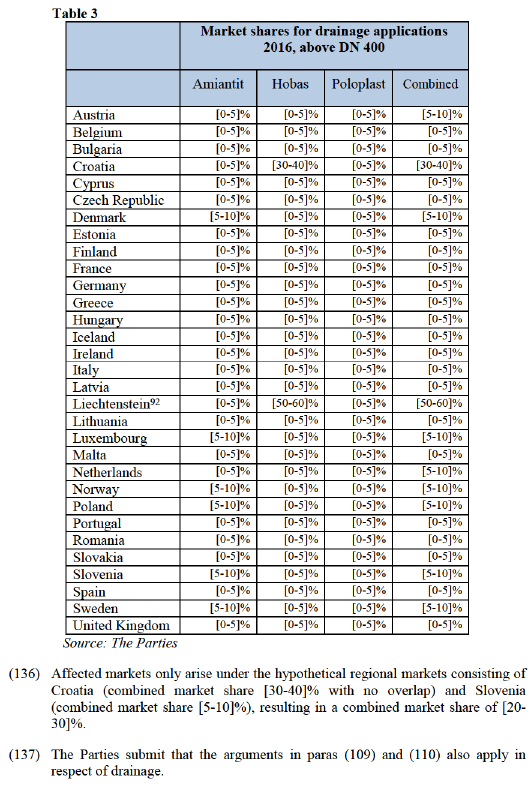

(135) As regards drainage, in line with the narrowest market definition as described above, the Commission has assessed the effects of the transaction on large diameter pipes for drainage of GRP, plastics and concrete at national level. Even under this narrow market definition, the transaction does not raise any affected market. (See Table 3)

(138) The market investigation has not indicated any concerns related to the Croatian and /or Slovenian market.

(139) As regards Member States where Hobas has over 30% market share and the other Party is not active, i.e. Croatia and Liechtenstein for drainage applications, the Parties submit that Amiantit [BUSINESS SECRET relating to current sales strategy of Amiantit].

(140) The Commission considers that, although these markets could be regarded as technically affected in the meaning of Section 6.4 Form CO, serious doubts appear unlikely in light of the competitive structure of their neighbouring markets.

(141) As concerns drainage pipes for small diameters including plastics and GRP, market shares are even lower than for large diameters, therefore, no affected markets arise on any of the national markets in the EEA.

(142) The concentration does not lead to affected markets for small diameter plastic and GRP pipes for drainage applications on a regional revel, under any alternative grouping of neighbouring countries.

(143) As noted in para (116), the arguments described in paras (117) to (123) also apply to drainage.

(144) In conclusion, the Transaction does not raise serious doubts as to its compatibility with the internal market in any national market for drainage pipes.

Other applications

(145) Considering the pressure applications irrigation, water supply and hydro-power above 400mm, including plastic, GRP and steel pipes, the Transaction does not result in affected market on any national market.

(146) Equally, when considering the same pressure applications below 400mm including plastic and GRP, the Transaction does not result in affected market on any national or regional market.

(147) Finally, for the application of micro-tunnelling, including all plastics and GRP, the Transaction does not lead to affected markets either for small diameters or for large on any national or regional market.

(148) In conclusion, the Transaction does not raise serious doubts as to its compatibility with the internal market in any national market for pipes applied for pressure applications and micro-tunnelling.

Non-circular pipes

(149) The Transaction does not result in affected market on any national or regional market for non-circular pipes.

5. CONCLUSION

(150) For the above reasons, the European Commission has decided not to oppose the notified operation and to declare it compatible with the internal market and with the EEA Agreement. This decision is adopted in application of Article 6(1)(b) of the Merger Regulation and Article 57 of the EEA Agreement.

1 OJ L 24, 29.1.2004, p. 1 (the 'Merger Regulation'). With effect from 1 December 2009, the Treaty on the Functioning of the European Union ('TFEU') has introduced certain changes, such as the replacement of 'Community' by 'Union' and 'common market' by 'internal market'. The terminology of the TFEU will be used throughout this decision.

2 OJ L 1, 3.1.1994, p. 3 (the 'EEA Agreement').

3 In the centrifugal casting process the pipes are built up in a rotating mould from the outer skin to the inner liner by applying layers of resin, chopped glass fibers and mineral reinforcement. The exact composition varies according to its diameter, pressure and stiffness. Specific designs exist according to stiffness, pressure and diameter requirements.

4 The continuous filament wound process is based on an advancing mandrel technology produce pipes. The pipes are built up on top of the mandrel from the inner liner to the outer skin by applying layers of resin, chopped glass, continuous filament glass roving and sand. The exact composition varies according to diameter, pressure and stiffness.

5 Approximately one third of Amiantit's sales occur in raw water/irrigation pipes.

6 See e.g. confirmed non-confidential submission of a GRP competitor on 17 March, 2017 or confirmed non-confidential minutes of a conference call with a GRP competitor on 3 April, 2017 or confirmed non-confidential minutes of a conference call with a German utility company on 2 May, 2017 or confirmed non-confidential minutes of a conference call with an international construction company on 28 March, 2017.

7 M.6563 – Mexichem SIH/Wavin, paras 27-30.

8 M.565 – Solvay/Wienerberger, para 18-19 and 21.

9 M.2294 – Etexgroup/Glynwed Pipe Systems, para 9.

10 M.1644– Wienerberger/DSCB/Steinzeug, para 20.

11 Ibidem.

12 M.1047 - Wienerberger/Cremer & Breuer as referred to in Case M.1644– Wienerberger/DSCB/Steinzeug, para 12.

13 M.6563 – Mexichem SIH/Wavin, paras 31-33.

14 See reports Gravity Pipes, the European Market 2015, October 2016, AMI Consulting ('AMI Report' and Market Study: Pipes Europe – September 2014, Cerasana ('Cerasana report').

15 See for instance Fascicule no 70 and 71 in France or ATV 127 in Germany, ӦNORM B5012 in Austria for sewage and drainage applications.

16 See replies to question 8 to Q1-Questionnaire to Pipe Customers and e.g. confirmed non- confidential minutes of a conference call with a GRP pipe manufacturer on 24 March, 2017.

17 See e.g. confirmed non-confidential minutes of a conference call with a German material certification body on 2 May 2017.

18 See e.g. confirmed non-confidential minutes of a conference call with a multinational industrial customer on 2 May 2017.

19 See AMI report and Cerasana Report and replies to question 6 of Q1 – Questionnaire to Pipe Customers.

20 See AMI Report.

21 See Cerasana Report.

22 See confirmed non-confidential minutes of a conference call with a GRP manufacturer, on 3 April 2017 and confirmed non-confidential minutes with another GRP pipe manufacturers on 10 May 2017.

23 See replies to question 26 of Q1- Questionnaire to Pipe Customers.

24 See e.g. confirmed non-confidential minutes with a German utility company on 2 May, 2017.

25 See replies to question 6 of Q1- Questionnaire to Pipe Customers.

26 Se e.g. confirmed non-confidential minutes of a conference call with a German material certification body on 2 May, 2017.

27 See AMI Report- p.220.

28 See also Commission precedent case IV/M.1047 - Wienerberger/Cremer & Breuer as reffered to in Case IV/M.1644– Wienerberger/DSCB/Steinzeug and e.g. non-confidential submission of a GRP competitor on 17 March 2017.

29 Ibidem, p.221.

30 See replies to question 5 of Q2- Questionnaire to Competitors.

31 See replies to question 7 of Q1- Questionnaire to Pipe Customers.

32 See for instance [an Amiantit 2016 internal document].

33 See non-confidential submission of a GRP competitor on 17 March 2017.

34 See e.g. confirmed non-confidential minutes of a conference call with a pipe competitor on 29 May, 2017 and replies to question 12.2 of Q1- Questionnaire to Pipe Customers.

35 See non-confidential submission of a GRP competitor on 17 March 2017.

36 See replies to question 5 of Q2- Questionnaire to Competitors.

37 The Parties add that in France, due to specific traditions, ductal iron enjoys a specific position in public infrastructure projects such as water supply, therefore the relatively high proportion of closed tenders, which further inhibits the penetration of GRP onto the French market.

38 See replies to question 24 of Q1 – Questionnaire to Pipe Customers.

39 See e.g. confirmed non-confidential minutes of a conference call with a GRP competitor on 18 July, 2017 or confirmed non-confidential minutes of a conference call with a customer on 17 July, 2017 or see also replies to question 24 of Q1 – Questionnaire to Pipe Customers.

40 See standards ISO 15014 and CEN/TC 15.

41 See e.g. British Standard BS EN 752:2008 Drain and sewer systems outside buildings and Fascicule no 70 and 71 in France, Fourniture et pose de conduites d´adduction et de distribution d´eau, Cahier des clauses techniques générales– Avril 2003.

42 See e.g. confirmed non-confidential minutes of a conference call with an international construction company specialised in sewage applications, on 17 July, 2017.

43 See replies to question 7 of Q1 - Questionnaire to pipe customers and also confirmed non- confidential minutes of a conference call with a Polish construction company specialised in sewage applications, on 30 March, 2017 or confirmed non-confidential minutes of a conference call with a GRP competitor, on 29 May, 2017.

44 See replies to question 7 of Q1 – Questionnaire to Pipe Customers.

45 See confirmed non-confidential minutes of a conference call with a German material certification body on 2 May, 2017.

46 Even if the parties activities overlap for GRP, some respondents to the market investigation even pointed at the fact that GRP pipes made by the merging Parties are rather different in terms of the technology they use and therefore of the technical characteristics of the pipes. See e.g. confirmed non-confidential minutes with an Austrian customer on 17 July 2017 and with a Hungarian GRP competitor on 10 May 2017.

47 See confirmed non-confidential minutes of a conference call with a competitor, 29 May, 2017.

48 See confirmed non-confidential minutes of a conference call with a GRP competitor on 18 July 2017.

49 See confirmed non-confidential minutes of a conference call with a German material certification body on 2 May, 2017.

50 See confirmed non-confidential minutes of a conference call with a GRP competitor on 18 July 2017.

51 See replies to question 26 of Q1- Questionnaire to Pipe Customers.

52 See replies to question 12.1 of Q1-Qeustionnaire to Pipe Customers.

53 See replies to question 12.2 of Q1- Questionnaire to Pipe Customers.

54 See replies to questions 9 and 12 of Q1 - Questionnaire to Pipe Customers.

55 See for instance internal document [an Amiantit 2016 internal document].

56 See reply of a German customer active in wastewater collection and treatment to question 15.1 of Q1 - Questionnaire to Pipe Customers.

57 See confirmed non-confidential minutes of a conference call with a German material certification body, on 2 May, 2017.

58 See confirmed non-confidential minutes of a conference call with a Hungarian GRP pipe manufacturer, on 10 May, 2017.

59 See replies to question 15.2 of Q1 - Questionnaire to Pipe Customers.

60 As concerns sewer relining, the alternatives included not just pipes of other materials, but also alternative techniques to pipe laying, such as the CIPP (Cure-in-Place process or other renovation techniques.

61 See replies to questions 15.2 and 7 of Q1 - Questionnaire to Pipe Customers.

62 See replies to question 7 of Q1 - Questionnaire to Pipe Customers.

63 See confirmed non-confidential minutes of a conference call with a GRP competitor on 4 April, 2017.

64 Internal document [A Hobas 2015 internal document and an Amiantit 2016 internal document].

65 See confirmed non-confidential minutes of a conference call with a Hungarian GRP pipe manufacturer, on 10 May, 2017.

66 See a GRP competitor's non-confidential submission on 17 March 2017.

67 See replies to question 13 of Q1 - Questionnaire to Pipe Customers and replies to question 11 of Q2- Questionnaire to Competitors.

68 See for instance confirmed non-confidential minutes of a conference call with a Hungarian GRP pipe manufacturer, on 10 May, 2017.

69 See confirmed non-confidential minutes of a conference call with a German customer also specialised in sewage renovations, on 28 March, 2017.

70 See non-confidential submission of a GRP competitor on 17 March 2017 and confirmed non- confidential minutes of a conference call with two GRP competitors on 4 April and on10 May, 2017.

71 See replies to question 13.2 of Q1 - Questionnaire to Pipe Customers and replies to question 11.2 to Q2 - Questionnaire to Competitors.

72 See confirmed non-confidential minutes of a conference call with a Polish construction company specialised in sewage applications, on 30 March, 2017.

73 M.2294 – Etexgroup/Glynwed Pipe Systems, para 15, M.1644– Wienerberger/DSCB/Steinzeug, para 23.

74 M.565 – Solvay/Wienerberger, paras 24-25.

75 M.6563 – Mexichem SIH/Wavin, paras 40-41.

76 See replies to question 17of Q2 - Questionnaire Competitors.

77 See replies to questions 18 of Q2 – Questionnaire to Competitors.

78 See replies to questions 16 of Q1 – Questionnaire to Pipe Customers.

79 The Parties submit that the market share for Liechtenstein represent only a very rough estimate, as none of the Parties have sales offices there and the size of the total market is not known to them.

80 Such alternative regional markets could for instance consist of grouping Bulgaria (combined market share (20-30)%) with Greece (combined market share (0-5)%) and/ or Romania (combined market share (0-5)%). Liechtenstein (combined market share (50-60)%), Germany ((10-20)%) and Austria (5-10)%) could constitute another regional market.

81 A further combination of Croatia, Slovenia and Austria, or Croatia, Slovenia, Austria, Hungary and Slovakia does not lead to affected markets.

82 See non-confidential submission of a GRP competitor on 17 March, 2017.

83 See replies to question 8 of Q1- Questionnaire to Pipe Customers.

84 See confirmed non-confidential minutes of a conference call with five customers and a competitor on 14 and 17 July, 2017.

85 '…GRP pipes offer technical advantages … Nonetheless, concrete pipes would be an alternative' and N principle, concrete pipes can be considered an alternative to GRP, even for pipes with a higher than 400mm diameter'. - See confirmed non-confidential minutes of a conference call with two Austrian customers on 14 and on17 July, 2017.

86 See replies to question 8 of Q1- Questionnaire to Pipe Customers.

87 'Prices increase, plants in Austria will be increasingly outsourced, suppliers from non-EU countries will want to participate in the market' - See replies to question 25 of Q1- Questionnaire to Pipe Customers.

88 See replies to question 35 to Q1- Questionnaire to Pipe Customers.

89 See an Austrian customer's reply to question 35 to Q1- Questionnaire to Pipe Customers.

90 Such alternative regional markets could for instance consist of grouping Bulgaria (combined market share (20-30)%) with Greece (combined market share (0-5)%) and/ or Romania (combined market share (0-5)%). Belgium (combined market share (20-30)%), Germany ((10-20)%) and France ((10-20)%) could constitute another alternative regional market.

91 A further combination of Croatia, Slovenia and Austria, or Croatia, Slovenia, Austria, Hungary and Slovakia does not lead to affected markets.

92 The Parties submit that the market share for Liechtenstein represent only a very rough estimate, as none of the Parties have sales offices there and the size of the total market is not known to them.