Commission, July 2, 2019, No M.9353

EUROPEAN COMMISSION

Judgment

ADVENT INTERNATIONAL CORPORATION / EVONIK METHACRYLATES BUSINESS DIVISION

Subject: Case M.9353 – ADVENT INTERNATIONAL CORPORATION / EVONIK METHACRYLATES BUSINESS DIVISION

Commission decision pursuant to Article 6(1)(b) of Council Regulation No 139/20041 and Article 57 of the Agreement on the European Economic Area2

Dear Sir or Madam,

(1) On 23 May 2019, the European Commission received notification of a proposed concentration pursuant to Article 4 of the Merger Regulation by which Advent International Corporation (“Advent” or “Notifying Party”) intends to acquire sole control over the methacrylates business division of Evonik Industries AG (“Evonik Methacrylates” or the “Target”).3 Advent and the Target are collectively referred to as the “Parties”.

1. THE PARTIES

(2) Advent is a private equity investor based in the United States. Advent controls a portfolio company, Allnex, active worldwide in the production of resins for coatings (“coating resins”). Coating resins are in turn used in a variety of products, including coatings and paints, where these resins determine the performance characteristics of these products (including, e.g. durability, flexibility and resistance).4

(3) The Target is a business division of Evonik Industries AG (“Evonik”, Germany) with assets in Germany, the United States, and China. It is active worldwide in the manufacture and supply of methyl methacrylate (“MMA”) and other methacrylate monomers derived from MMA (“MMA derivatives”), which are chemicals used for a variety of applications, including plastics, acrylics, adhesives, varnishes, polishes, textile binders, coatings and resins. The Target manufactures and supplies certain types of methacrylate resins, some of which are also produced by Allnex. Finally, the Target is active in the manufacture and supply of polymethyl methacrylate (“PMMA”, manufactured using MMA) molding compounds and acrylic products, and cyanides.

2.THE OPERATION AND CONCENTRATION

(4) Pursuant to a master sale and purchase agreement entered into on 4 March 2019 between an acquisition vehicle ultimately owned by funds advised by Advent (as buyer) and Evonik (as seller), Advent will acquire 100% of – and sole control over – the assets and shares constituting the Target (the “Transaction”).

(5) Therefore, the Transaction constitutes a concentration within the meaning of Article 3(1)(b) of the Merger Regulation.

3. EU DIMENSION

(6) The undertakings concerned have a combined aggregate world-wide turnover of more than EUR 5 000 million5 ([Advent’s worldwide turnover], [Target: approx. EUR 2 billion]). Each of them has an EU-wide turnover in excess of EUR 250 million ([Advent’s EU-wide turnover], [Target’s EU-wide turnover]), but they do not achieve more than two-thirds of their aggregate EU-wide turnover within one and the same Member State. The notified operation therefore has an EU dimension.

4. RELEVANT MARKETS

4.1.Activities of the Parties

(1) Advent’s portfolio company Allnex

(7) In 2013, Advent acquired the coating resins business of Cytec Industries Inc, which was renamed Allnex (and which Advent currently controls). In 2016, Advent acquired Nuplex Industries, which it subsequently merged with Allnex.6 As a result, Allnex is currently active in the manufacture of coating resins, some of which use MMA and MMA derivatives as inputs.7

(8) Coatings are chemical formulations that can be applied in a thin layer (or film) onto a particular substrate (e.g. metal, wood) to provide decorative, protective or other functional effects on a surface.8 Resins are intermediate ingredients that act as binders in the production of coatings, paints and inks. Resins bind the various components of a coating or paint together into a film, and bond the film to the substrate. The film protects the substrate and improves its decorative appeal.9

(9) Resins are essential elements of the coatings formulation as resins determine the performance characteristics of the coatings, such as gloss, durability, smoothness, flexibility, weatherability and resistance.10 Common chemistries of coating resins based on the base chemical component of the resin include acrylics, alkyds, epoxies. Coating resins of some chemistries may be used in more than one type of delivery technology for end products, e.g. liquid or powder. The most common delivery technologies for coating resins include water-borne (commonly used in coatings and paints), solvent-borne (also commonly used in paints and allows for higher metal adhesion and corrosion resistance), powder-based (particularly suitable for metal coatings and other applications where durability and performance are important) and radiation-curable (especially suited for use in graphic arts and coatings or industrial applications).11

(10) Allnex is active in the EU, the USA, China and Australia, where it also has manufacturing facilities.12

(2) The Target

(11) The Target manufactures MMA, a colourless organic compound used in the manufacture of PMMA molding compounds, acrylic products, impact modifiers, acrylic latexes, lacquers, enamels, and resins for use in specialty chemicals and coatings.13 Other important applications for MMA include emulsion polymers principally for paper, textiles, leather and floor polishes, mineral-filled sheet, polyesters, polymer concrete, and adhesives.14 The Target sells part of its MMA production on the merchant market and uses part for the captive manufacture of PMMA molding compounds and acrylic products.15

(12) The Target also manufactures MMA derivatives that are used downstream in inter alia surface coatings either as inputs for coating resins or as direct inputs in coating formulations,16 namely: a. Glacial methacrylic acid (“GMAA”), whose crude form is methacrylic acid (“MAA”), a clear, colourless liquid, completely soluble in water and soluble in most organic solvents. MAA exhibits specific properties, such as good chemical resistance, improved freeze-thaw resistance, enhanced surface adhesion, toughness, and colloidal stability in emulsions.17 In addition to its use in coating resins, MAA is used in a variety of applications, including in the production of other methacrylates (by direct esterification), in construction chemicals, adhesives and sealants, paints and coatings, emulsion polymers, composites, paper and textile applications.18 b. Butyl methacrylate (“BUMA”) is a methacrylate monomer that is used mainly in the manufacture of coating resins and acrylic polymers for surface coatings, where it imparts desirable properties, such as weatherability, UV resistance and flexibility, to acrylic lacquers and acrylic emulsion polymers for interior and exterior water-based paints.19 The Target manufactures both n-butyl methacrylate and i-butyl methacrylate.20 c. Hydroxyesters or hydroxy methacrylates (“HYMA”) is a methacrylate monomer that can be used in coatings, resins (including coating resins), polymers, and paints, are recommended for heat or room temperature cured coatings with permanent marring and solvent resistance, high gloss retention and weatherability and can also serve as adhesion promoters in reactive resins for bonding to metal surfaces.21 The Target manufactures 2-hydroxyethyl methacrylate, which is a clear, colourless liquid that can be used as an adhesion promoter for polymers, in thermosetting paints, hydrophilic polymers and light-curing polymer systems,22 and hydroxypropyl methacrylate, which is a functional monomer that can copolymerize with other monomers to produce copolymers with a hydroxy group in the side chain, and whose main applications are coatings and reactive resins.23 d. Methacrylamide is a monomer whose amino functional variety manufactured by the Target can be used to improve pigment wetting and substrate adhesion to polymers and that can be used in coating resins, paints and coatings,paper, water, cosmetic and oil and gas applications.24 The Target also manufactures a bifunctional monomer that possesses both vinyl and hydroxymethyl groups, suitable for a range of applications from adhesives and binders in papermaking, textiles and non-wovens, to a variety of surface coatings and resins for varnishes, films and sizing.25

(13) The Target also manufactures a small range of coatings using MMA and MMA derivatives for sale on the merchant market. 26

(14) Other activities of the Target include the manufacture of: (i) PMMA molding compounds, which it sells on the merchant market and uses in a captive manner to manufacture acrylic products (such as sheets, blocks and pipes), also sold on the merchant market;27 and (ii) sodium cyanide and potassium cyanide, which are produced from hydrogen cyanide, a raw material in MMA production. 28

(15) The Target has MMA and MMA derivatives production plants in Germany (at Worms and Wesseling), the USA (in Fortier, Louisiana) and China (in Shanghai).29

4.2.The upstream markets – manufacture and supply of MMA and MMA derivatives

4.2.1.Relevant product market definition

4.2.1.1. The Notifying Party’s views

(16) The Notifying Party submits that the exact market definition can be left open, as no competition concerns arise even on narrowly defined markets for MMA and each of the MMA derivatives separately.30

(17) With regard to MMA in particular, the Notifying Party submits that a hypothetically distinct market for MMA should not be sub-segmented further given the highly homogenous nature of these products.31

(18) With regard to MMA derivatives, notwithstanding the Notifying Party’s view that the relevant market can be defined for each MMA product separately,32 the Notifying Party submits that there is a degree of supply-side substitutability given that their manufacture results from modifications to the MMA production process. Therefore, in the Notifying Party’s view, the same production process and assets can be used to manufacture MMA and MMA derivatives and most suppliers of MMA are also capable of producing most MMA derivatives (and often do). The Notifying Party admits, however, that some adjustments to the MMA production process or the addition of specific production assets may be required to carry out the final reactions necessary to manufacture certain MMA derivatives (e.g. ethoxylation capacity in order to manufacture BUMA, and transesterification assets to convert MMA to HYMA).33

(19) With regard to methacrylamide, which is derived from an intermediary step of the Target’s MMA manufacturing process (and not from MMA, as is the case with the other MMA derivatives), the Notifying Party submits that the same market definition considerations apply as for other MMA derivatives, and that the market for the supply of methacrylamide may accordingly be viewed as a distinct product market.34

4.2.1.2.The Commission’s assessment

(20) In previous decisions, the Commission considered that: a.the supply of MMA constitutes a separate product market, as it cannot be replaced by other products in the manufacture of follow-on products;35 b.the supply of MAA (the crude form of GMAA)36 constitutes a separate product market, distinct from MMA, since MAA and MMA confer different properties on the products into which they are processed and are not interchangeable from the user’s point of view;37 c.the exact market definition for the supply of butyl methacrylate (BUMA) and its potential segmentation into n-butyl methacrylate and i-butyl methacrylate can be left open;38 and d.it cannot be excluded that hydroxy methacrylate (HYMA) and hydroxy acrylates belong to a single product market in view of the fact that, at the formulation stage, they appear to be substitutable for several applications (though the exact market definition was ultimately left open).39

(21) The relevant product market for methacrylamide has not been previously defined by the Commission.

(22) The results of the market investigation carried out in the present case indicate that each of the markets for the manufacture and supply of MMA, GMAA, BUMA, HYMA and methacrylamide are likely to constitute a distinct relevant product market.

(23) From a demand-side perspective, the majority of coating resin manufacturers that responded to the Commission’s market investigation consider each of MMA, GMAA, BUMA and HYMA to be an essential and irreplaceable component in their manufacturing processes for a significant number of coating chemistries.40 As one customer explained: “Methacrylate monomers are a major raw material critical for the production of many products in [that customer’s] coatings resin portfolio”.41 A key reason for this is that each of these monomers imparts particular characteristics to the final product and, therefore, cannot be easily replaced by any other component.42 As another customer explained: “Replacing methacrylates by other monomers changes the performance in the final application.”43 Hence, there seems to be very limited, if any, demand-side substitutability between MMA and the various MMA derivatives.

(24) The results of the Commission’s market investigation also do not fully support the Notifying Party’s views on supply-side substitutability. In particular, suppliers of MMA and MMA derivatives typically do not manufacture and supply the full range of monomers. While all those suppliers manufacture and sell MAA on the merchant market, a much more limited number of suppliers also supply GMAA, BUMA, and even less so, HYMA and methacrylamide. According to the results of the market investigation, the Target may be the only supplier on the merchant market to supply all of MMA, GMAA, BUMA, HYMA and methacrylamide. Other suppliers sell predominantly MMA or GMAA, and only a few sell BUMA or HYMA.44

(25) Different suppliers of MMA and MMA derivatives also appear to have different strengths in the monomers they supply. For example, whilst the majority of respondents to the Commission’s market investigation have ranked the Target as the top supplier of GMAA, BUMA and methacrylamide in the EEA, another supplier was generally ranked higher than the Target for the supply of MMA and yet another supplier was ranked number one (tied with the Target) for the supply of HYMA.45

(26) It is worthwhile to note, also, that different suppliers use different processes and even different variations of the same process for the manufacture of MMA, though the final product is generally considered to be identical and chemically indistinguishable.46

(27) There are three different processes for the manufacture of MMA that are currently commercialised: (1) the acetone cyanohydrin (“ACH”) process (the “ACH process”), (2) the oxidation/esterification of isobutylene or tertiary-butyl alcohol (“TBA”) (the “TBA process”), and (3) the hydroformylation of ethylene to propionaldehyde, propionic acid, or methyl propionate (the “ethylene process”).47 Each of these processes (and their variants) involve a different number of steps, use different feedstocks and produce different by-products, as well as entailing different steps for the manufacture of MMA derivatives, which may to a certain extent explain the differences in the supply by the different suppliers: a. The ACH process typically involves three steps, namely (i) the production of ACH from acetone and hydrogen cyanide, (ii) treating ACH with sulphuric acid to produce methacrylamide sulphate (iii) reacting methacrylamide sulphate with methyl alcohol to produce MMA (with sulphuric acid and ammonium bisulphate as by-products). The crude MMA is then purified by distillation.48 Different variants of the ACH process exist. For example, the Mitsubishi Gas Chemical Company uses a different type of the ACH process that does not use sulphuric acid or generate by-product ammonium bisulphate.49 The Target’s own process is also a variant of the ACH process, one that employs an inorganic catalyst instead of sulphuric acid and does not generate the by-product ammonium bisulphate.50 To manufacture different methacrylates using the ACH process, different alcohols are typically added to the MMA solution. For example, to manufacture BUMA, MMA is reacted with butyl alcohol (butanol).51 However, with respect to some of the other MMA derivatives at issue in this case specifically, their manufacture requires more modifications than simply substituting one type of alcohol for another in the same step of the manufacturing process. Thus, to manufacture GMAA, water is used instead of methanol in the third step of the reaction, resulting in MAA, which is then purified to produce GMAA.52 HYMA is produced from the esterification of GMAA.53 Methacrylamide is produced by stopping the second step of the ACH process and converting the resulting product, methacrylamide sulphate, to methacrylamide.54 b. Some suppliers in Asia use the TBA process, which in the first step, oxidises TBA to methacrolein, which is then in turn oxidised to MAA in the second step, followed by the esterification of MAA with methanol to produce MMA in the third step.55 Compared to the ACH process, the TBA process uses a different feedstock,56 does not require hydrogen cyanide or sulphuric acid, does not generate acidic waste, but has higher capital costs per ton of capacity.57 In the TBA process, MAA (the crude form of GMAA) is actually an intermediate product for the production of MMA, instead of an alternative manufactured using a different alcohol, as is the case in the ACH process. A supplier based in Asia, Asahi, has developed a variant of the TBA process that uses two steps instead of three and has lower capital and production costs than the three-step process.58 c. There are three variants of the ethylene process: the variant using propionaldehyde produces MMA in a series of four steps (with MAA produced as an intermediary product), whereas the propionic acid variant and the methyl propionate variant consist of three and two reaction steps, respectively (the second of which does not entail the production of MAA as an intermediary step). Lucite International has a plant in Singapore that uses a proprietary variant of the ethylene process, the Alpha process, which consists of only two reaction steps and manufactures only small volumes of MAA as a by-product.59

(28) A competitor active in the supply of several MMA monomers explained that, while there are no technical barriers to switching to the production of MMA derivatives, it does demand a long-term recoup plan on investment costs, as the markets for MMA derivatives are smaller than that for MMA.60 Nevertheless, entry into MMA derivatives by suppliers that already own MMA production assets is still feasible as “the incremental capital to produce these is significantly lower than the capital required for MMA or MAA”.61 Nevertheless, with regard to e.g. BUMA, a competitor estimates that “once a producer has an MMA asset, it would cost tens of millions of euros to install an asset to manufacture BUMA”.62

(29) On the basis of the above considerations supported by evidence collected over the course of the market investigation, the Commission considers that each of the markets for the supply of MMA, GMAA, BUMA, HYMA and methacrylamide likely constitutes a distinct product market. For the purposes of this decision, however, the exact product market definition can be left open, as no serious doubts arise under any plausible market definition.

4.2.2.Geographic market definition

4.2.2.1. The Notifying Party’s views

(30) The Notifying Party submits that the geographic scope of the supply of each of MMA, GMAA, BUMA, HYMA and methacrylamide is global in scope (and at least EEA-wide in the case of methacrylamide).63

(31) The Notifying Party argues that the supply of MMA (and therefore also of the MMA derivatives) exhibits features of a market that is wider than EEA in geographic scope, namely because of: (i) the significant trade flows across world regions (with imports of c.20% on the merchant market in the EU in 2017), (ii) expected increased imports into Europe from two new plants coming into production in Saudi Arabia, (iii) the low cost of transport of MMA and MMA derivatives (with the exception of GMAA, the transport costs of which are higher because temperature control is required), and (iv) the fact that supply can be, and has on previous occasions been,diverted to other world regions (e.g. Europe or Asia) when market fluctuations meant that prices in those regions increased.64

(32) In the Notifying Party’s view, the market definition can ultimately be left open as no competition concerns arise irrespective of whether these markets are defined as global or EEA-wide in scope.65

4.2.2.2.The Commission’s assessment

(33) The Commission has previously defined the geographic markets for the supply of MMA and of MAA (the crude form of GMAA) as at least EEA-wide in scope and for the supply of hydroxy monomers (including HYMA) as EEA-wide in scope, whereas it left open the geographic scope of the markets for the supply of butyl methacrylate (including BUMA).66

(34) The results of the market investigation indicate that the markets for the supply of MMA and each of the MMA derivatives are likely to be EEA in geographic scope.

(35) Whilst some of the competitors have indicated that they supply, and some of the customers indicated that they purchase, MMA and MMA derivatives on a global level, a significant number of customers that responded to the Commission’s market investigation indicated that they tend to purchase MMA and MMA derivatives from EEA-based suppliers for use in the EEA.67 As one customer explained, “[w]e are a global company but we buy methacrylates in Europe for the European plants (like we buy in China for our plant in China, in the US for the US plants, …)”.68

(36) The reasons for choosing to source mainly from regional suppliers relate to a large extent to the limited shelf-life of MMA monomers and the related storage requirements. As another EEA-based customer explained, “[d]ue to large volume requirements and only limited storage capabilities, short lead times are required to source monomers”, which is why its “[v]olumes are typically sourced from the main EEA countries in which monomers are produced”.69 An MMA manufacturer explained that the typical shelf life of MMA and MMA derivatives is six months.70

(37) Moreover, importing from outside the EEA may be difficult, if not impossible, for certain EEA-based customers due to a variety of economic, technical or regulatory factors. For example, certain technical specifications of EEA customers require the use of specific stabilisers or inhibitors to make MMA and the relevant MMA derivatives safe for transport and subsequent handling and use in follow-on manufacturing processes. Products from outside the EEA (e.g. Asia) often utilise Topanol-A, an inhibitor that is not suitable for use for certain applications in the EEA (where MEHQ is typically used).71 The water content or necessary temperature controls also entail additional costs,72 as do customs duties73 and additional risks and logistics considerations related to transportation of these chemicals over long distances.74

(38) In addition, customers procuring volumes of MMA and MMA derivatives originating from outside the EEA do so via EEA-based traders precisely because they value geographic proximity. For example, one customer explained that it procures volumes of MMA and MMA derivatives from overseas but only via traders based in the Netherlands, Germany and the UK.75 Another customer explained that whilst they have approved non-EU sources in order to improve their security of supply and leverage global market dynamics, they do not import from any of their approved non-EEA suppliers themselves, relying instead on EEA-based importers.76

(39) Furthermore, the reliability of imports of MMA and MMA derivatives from outside the EEA as competitive constraints in the EEA appears relative and unstable. First, according to the views expressed by MMA and MMA derivatives customers responding to the Commission’s market investigation, imports are not always competitively priced as compared to monomers manufactured in the EEA. As one customer explained: “If the market is tight with a strong demand in both regions, Asian imports can be at a premium to EU prices.”77 Another customer explained that the “[c]ompetitiveness of imports of methacrylate monomers from outside the EEA is highly dependent on market circumstances”, noting that “[u]nder normal circumstances EEA produced material is more competitive.”78 This suggests that imports from outside the EEA remain opportunistic,79 becoming more significant at times markets in the EEA are disrupted and prices increase as a result of e.g. capacity restrictions at EEA-based manufacturing facilities.80

(40) For these reasons, the Commission finds that each of the geographic markets for the manufacture and supply of MMA, GMAA, BUMA, HYMA and methacrylamide is likely to be EEA-wide in scope. For the purposes of this decision, however, the exact geographic market definition can be left open, as no serious doubts arise under any plausible market delineations.

4.2.3.Conclusion on the relevant markets for the manufacture and supply of MMA and MMA derivatives

(41) On the basis of the above considerations supported by evidence collected over the course of the market investigation, the Commission concludes that each of the markets for the supply of MMA, GMAA, BUMA, HYMA and methacrylamide likely constitutes a distinct product market, which is likely to be EEA-wide in geographic scope. For the purposes of this decision, however, both the exact product and geographic market definition can be left open, as no serious doubts arise on any plausible market definition.

4.3.The downstream markets – manufacture and supply of coating resins

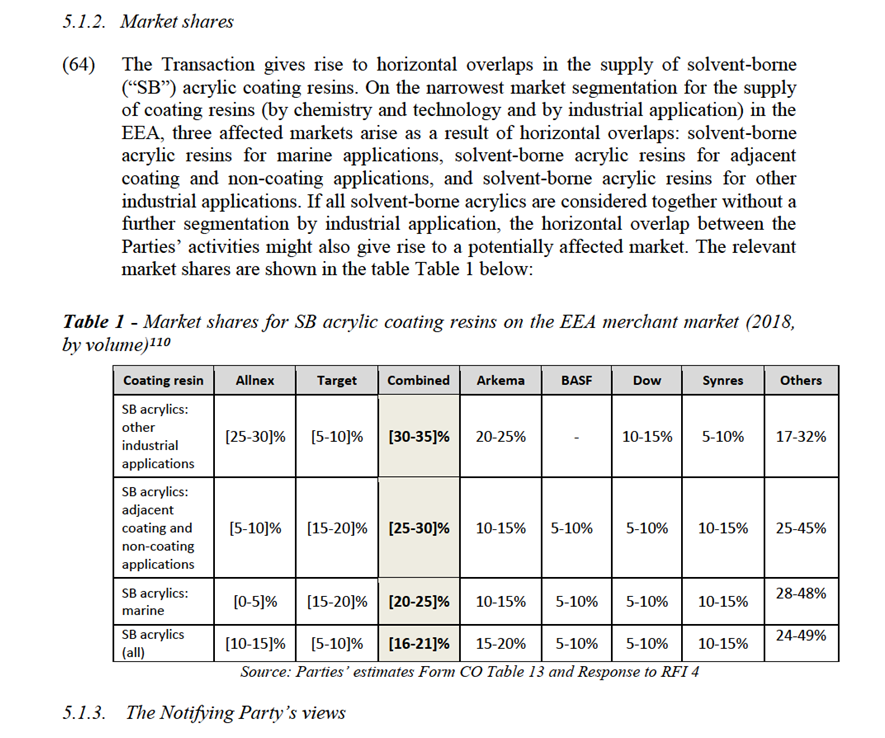

4.3.1.Relevant product market definition

4.3.1.1.The Notifying Party’s views

(42) The Notifying Party submits that for the purposes of a vertical assessment, the coating resins market should be viewed as one single market without further segmentation.81 In the Notifying Party’s view, a further sub-segmentation is not appropriate because: (i) coating resin manufacturers operate multi-purpose reactors in which they can easily switch between coating resin chemistries (and Allnex does so often, at very limited cost of between EUR 1 500 and EUR 3 000 and only a few hours of cleaning on average), (ii) customers can switch between different resin chemistries to achieve the desired effects in a coating for a particular end-use; (iii) coating resin manufacturers do not tend to be aware of their customers’ intended use of a given resin chemistry or, if they are, they are not willing to share this information with other third parties, meaning that any market estimates on narrower sub-segments are often only very high-level.82

(43) The Notifying Party further submits that in any event, the exact market definition can be left open as no competition concerns arise on any plausible market definition.83

4.3.1.2.The Commission’s assessment

(44) The Commission has previously considered84 a possible segmentation of the market for the supply of coating resins by chemistry and delivery technology as well as by industrial application: a. A segmentation by chemistry and delivery technology distinguishes between the following categories of coating resins: (i) solvent-borne acrylics, (ii) solvent-borne alkyds, (iii) water-borne acrylics, (iv) water-borne alkyds, (v) water-borne epoxies, (vi) water-borne polyurethane dispersions, (vii) cathodic electro-deposition resins, (viii) radiation- curablemonomers/oligomers/acrylates, (ix) radiation-curable UV-curable polyurethane dispersions, (x) radiation-curable glass laminates, and (xi) polyester powders. b. A segmentation by industrial application distinguishes between the following end-use applications for coating resins (within each chemistry): (i) automotive OEM, (ii) automotive refinish, (iii) industrial wood, (iv) coil and PCM, (v) other industrial, (vi) marine, (vii) special purpose, (viii) packaging, (ix) architectural, and (x) adjacent coating and non-coating.

(45) In Advent International/Nuplex Industries, the Commission concluded that, based on the results of the market investigation in that case, a segmentation of the market based on (i) the delivery technology (e.g. liquid or powder) and the resin chemistry (e.g. acrlyics or alkyds) and (ii) industrial application (e.g. automotive OEM or architectural) was likely to be the most suitable (e.g. solvent-borne acrylics for automotive OEM), though ultimately leaving the exact relevant product market definition open.85

(46) The results of the market investigation carried out in the present case confirm the segmentation of the coating resins market by chemistry and delivery technology and by industrial application.

(47) The vast majority of coating resins manufacturers that responded to the Commission’s market investigation agree with the segmentation by chemistry and delivery technology and by industrial application outlined in paragraphs (44)a) and (44)b) above.86 As competitors explained with regard to the segmentation by chemistry and delivery technology, “[t]hese categories provide a good coverage for different market segments based on technology/chemistry platforms”87 and “[f]rom a chemical classification point of view, this segmentation is generally followed and corresponds to the main types of product categories”88 and with regard to the segmentation by end-use: “It reflects standard industry segmentation practice”.89 One competitor explained in particular that markets “are determined by a) chemistry an[d] b) application. Within each application there are possibly separate chemistries. Each chemistry can be used in different applications.”90

(48) The vast majority of coating resin customers that responded to the Commission’s market investigation also agreed with this segmentation by chemistry and delivery technology and by industrial application,91 noting that these different chemistries reflected the “different performance” of the coating resins92 and that this segmentation by industrial application is “commonly used” within the industry and is based on linking the product specificities to their application, “as the technical requirements are different” for different uses.93

(49) From the demand-side perspective, therefore, coating resins do not appear to be substitutable between different chemistries and end-applications. As one customer stated: “Different types of resins are not substitutable because of their different properties.”94 Another customer explained in more detail that: “The types of (specialty) resins used in one end-use application are generally not substitutable with the types of (specialty) resins used in another end-use application. Indeed, depending on the end-use application, the market needs and end requirements are different. Different types of resins are therefore used because of the properties they provide, such as chemical resistance, hardness, durability, curing time etc. as well as because of the application and curing method, and the substrate coated (metal or plastic). Their chemical composition and properties would differ, as well as the prices.”95

(50) As regards supply-side substitutability, the results of the market investigation did not confirm the Notifying Party’s view that it is generally easy to switch production lines across the different coating resin chemistries and applications. Whilst some coating resins manufacturers that focus on specific chemistries report being able to switch their production lines between their targeted resin chemistries, others say it would be very difficult for them to do so or that it “is not possible in general”.96 The reasons for this are numerous: the costs of reformulating recipes to use different raw materials may be very high, as are the costs of testing the reformulated coating resins for their intended end-applications by producers and customers alike.97

(51) On the basis of the above considerations supported by evidence collected during the market investigation, the Commission considers that it is appropriate to maintain the Commission’s practice of segmenting the supply of coating resins by chemistry and delivery technology and by industrial application, as outlined in paragraphs (44)a) and (44)b) above. For the purposes of the present decision, however, the exact product market definition can be left open, as no serious doubts arise under any plausible market delineations.

4.3.2.Geographic market definition

4.3.2.1.The Notifying Party’s views

(52) The Notifying Party submits that the supply of coating resins exhibits several features of a global or at least EEA-wide market, including: (i) low transportation costs, (ii) no regulatory barriers to trade across jurisdictions, and (iii) converging global pricing (with the exception of Asia, where prices are lower).98 However, according to the Notifying Party, the exact geographic market definition can be left open as no competition concerns arise under any plausible geographic market definition.99

4.3.2.2.The Commission’s assessment

(53) The Commission has previously considered the geographic market for the supply of coating resins (including water-based resins) to be EEA-wide in scope.100

(54) In the present case, the results of the market investigation suggest that the markets for coating resins are likely to be EEA-wide in geographic scope.

(55) Whilst some of the coating resins manufacturers that responded to the Commission’s market investigation indicated that they can sell coating resins on a global level, it is apparent that a number of these same suppliers typically serve customers at the EEA level. For example, one competitor stated: “We can supply globally, but typically we manufacture in the region which we serve”.101 Another explained that “[m]ain supplies are going into EEA, and only small volumes outside EEA”.102

(56) From the demand-side, the customers of coating resins tend to procure at the EEA level, typically from different EEA countries to diversify their supplier base. Regulatory requirements may render coating resins manufactured by non-EEA manufacturers unsuitable for EEA-based customers. Those responding customers that stated that they procure coating resins on a global level explain that they have “global manufacturing sites” or “factories in different regions” and that “[s]ome grades/types of [coating resins] are not available locally hence [they] need to import them”.103

(57) For these reasons, the Commission finds that the geographic markets for the supply of coating resins, including their possible segmentation by chemistry and delivery technology and by industrial application, are likely to be EEA-wide in scope. For the purposes of this decision, however, the exact geographic market definition can be left open, as no serious doubts arise under any plausible market definition.

4.3.3.Conclusion on the relevant markets for the manufacture and supply of coating resins

(58) On the basis of the above considerations supported by evidence collected during the market investigation, the Commission considers it appropriate to segment the market for the supply of coating resins by chemistry and delivery technology and by industrial application, as outlined in paragraphs (44)a) and (44)b) above, and to consider these markets to be EEA-wide in scope. However, the exact market definitions can be left open, as no serious doubts arise on any plausible market definition.

5. COMPETITIVE ASSESSMENT

5.1.Horizontal non-coordinated effects

5.1.1. Legal framework for the competitive assessment

(59) A merger giving rise to significant impediment of effective competition may do so as a result of the creation or strengthening of a dominant position in the relevant market(s). Moreover, mergers in oligopolistic markets involving the elimination of important constraints that the parties previously exerted on each other, together with a reduction of competitive pressure on the remaining competitors, may also result in a significant impediment to effective competition, even in the absence of dominance.104

(60) In fact, the Commission Guidelines on the assessment of horizontal mergers under the Merger Regulation (the “Horizontal Merger Guidelines”)105 describe horizontal non-coordinated effects as follows: “A merger may significantly impede effective competition in a market by removing important competitive constraints on one or more sellers who consequently have increased market power. The most direct effect of the merger will be the loss of competition between the merging firms. For example, if prior to the merger one of the merging firms had raised its price, it would have lost some sales to the other merging firm. The merger removes this particular constraint. Non-merging firms in the same market can also benefit from the reduction of competitive pressure that results from the merger, since the merging firms’ price increase may switch some demand to the rival firms, which, in turn, may find it profitable to increase their prices. The reduction in these competitive constraints could lead to significant price increases in the relevant market.”106

(61) The Horizontal Merger Guidelines list a number of factors which may influence whether or not significant horizontal non-coordinated effects are likely to result from a merger, such as the large market shares of the merging firms, the fact that the merging firms are close competitors, the limited possibilities for customers to switch suppliers, or the fact that the merger would eliminate an important competitive force.107 That list of factors applies equally regardless of whether a merger would create or strengthen a dominant position, or would otherwise significantly impede effective competition due to non-coordinated effects. Furthermore, not all of these factors need to be present to make significant non-coordinated effects likely and it is not an exhaustive list.108

(62) Finally, the Horizontal Merger Guidelines describe a number of factors, which could counteract the harmful effects of the merger on competition, including the likelihood of buyer power, the entry of new competitors on the market, and efficiencies.

(63) For the purposes of the competitive assessment of this case, in this Section, the Commission will assess whether the Transaction gives rise to horizontal non- coordinated effects. 109

5.1.4. The Commission’s assessment

(66) The following section sets out the Commission’s assessment of the likely impact of the Transaction on the supply of SB acrylic resins in the EEA and addresses each affected plausible market separately.

5.1.4.1. Supply of SB acrylic resins (all applications combined)

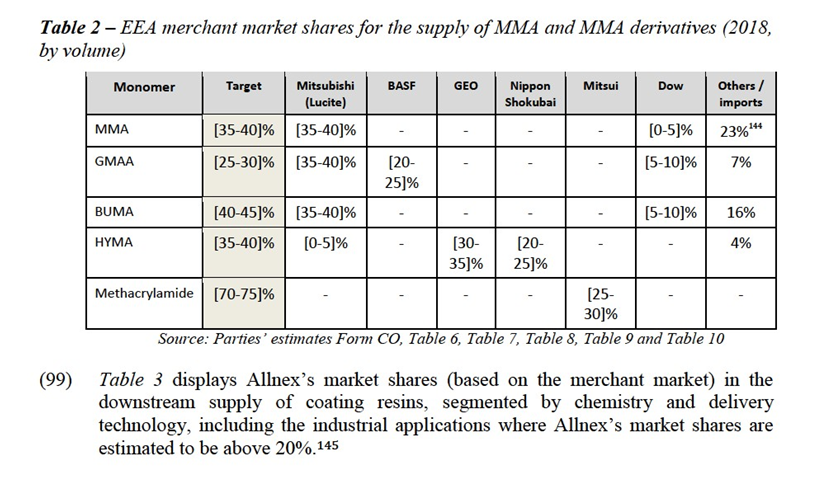

(67) Competition concerns are unlikely to arise as a consequence of the Parties’ horizontal overlap in the market for the supply of SB acrylic resins for all applications (where the Parties have an estimated combined market share of 16-20% and an increment of [5-10]%) for the following reasons.

(68) The results of the Commission’s market investigation reveal that for the plausible market encompassing the supply of all SB acrylic resins regardless of the end-use application, the combined market share of the Parties would remain relatively modest and multiple competitors appear to be able to constrain the merged entity post-Transaction, including Arkema, Synres, Dow or BASF, among others.112

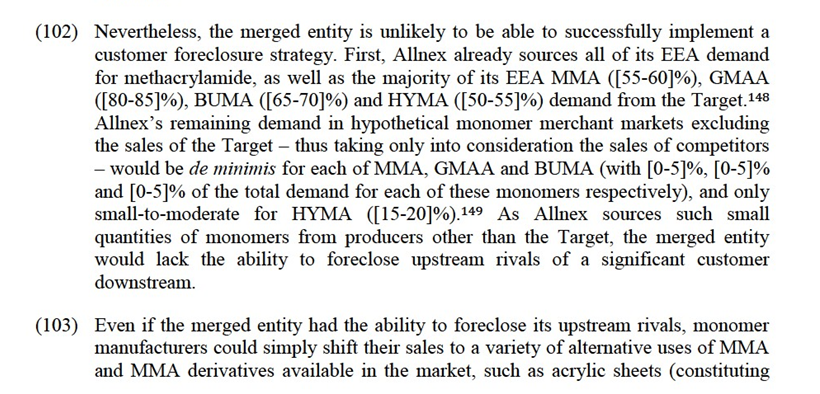

(69) Moreover, while some coating resins manufacturers have long-term relationships with customers, supply contracts are generally of a short duration in this industry (typically ranging between several months and 1 or 2 years113).114 Likewise, customers of SB acrylic resins agree that multi-sourcing is a common practice and that switching is possible in the industry,115 even though it may require finding a supplier that meets specific formulations or characteristics required by the customer.116

(70) In addition, as regards the Parties’ horizontal overlaps in SB acrylic resins, the results of the market investigation suggest that the large majority of customers and competitors do not expect the Transaction to have a material impact on their business.117 More importantly, the majority of customers expects that there will remain a sufficient number of suppliers in the market, and that there will be no increase in price or decrease in the quality of the product available in the market.118

(71) The Commission accordingly considers that the Transaction does not raise serious doubts as to its compatibility with the internal market as a result of horizontal overlaps in the Parties’ activities in the possible EEA market for the supply of SB acrylic resins.

5.1.4.2. Supply of SB acrylic resins for marine applications

(72) Competition concerns are unlikely to arise as a consequence of the Parties’ horizontal overlap in the market for the supply of SB acrylic resins for marine applications for the following reasons.

(73) First, the Parties’ combined market share is relatively modest, estimated by the Notifying Party to be [20-25]%, and the increment brought about by the Transaction is limited ([0-5]%).

(74) Second, the market is fragmented, with many competitors remaining available as alternative suppliers post-Transaction, including Arkema (with an estimated market share of 10-15%), BASF (5-10%), Dow (5-10%), Synres (10-15%), and a number of other competitors representing about a third of the market (28-48%).119

(75) Third, the majority of customers of SB acrylic resins for marine applications that responded to the Commission’s market investigation do not expect the Transaction to result in any price increases, reductions in quality or choice.120 The majority of these SB acrylic resins customers, and specifically the majority of customers of SB acrylic resins for marine applications, have indicated that a number of strategies would be available to them to respond to any increases of prices or decreases in volumes post-Transaction, including procuring adequate volumes of comparable quality and at comparable prices from alternative suppliers in the EEA.121

(76) The majority of competing suppliers of SB acrylic resins that responded to the Commission’s market investigation similarly do not expect the Transaction to result in any price increases, reductions in quality or choice in any of the SB acrylic resins for any end-applications.122 These conclusions did not significantly change for suppliers of SB acrylic resins for marine applications.

(77) The Commission accordingly considers that the Transaction does not raise serious doubts as to its compatibility with the internal market as a result of horizontal overlaps in the Parties’ activities in the possible EEA market for the supply of SB acrylic resins for marine applications.

5.1.4.3. Supply of SB acrylic resin for adjacent coating and non-coating applications

(78) As regards the market for the supply of SB acrylic resins for adjacent coating and non-coating applications (which includes resins not assigned to specific coating applications, such as textile or inks, and resins used for non-coatings applications such as rubber, tires and adhesives123), the Transaction is unlikely to raise any competition concerns for the following reasons.

(79) First, the Parties’ combined market share is relatively modest, estimated to be [25- 30]%. In addition, the increment brought about by the Transaction is limited ([5- 10]%).

(80) Second, the market is fragmented, with many competitors remaining available as alternative suppliers post-Transaction, including Arkema (with an estimated market share of 10-15%), BASF (5-10%), Dow (5-10%), Synres (10-15%), and a number of other competitors representing about a third of the market (25-45%).124

(81) Third, all customers of SB acrylic resins for adjacent coating and non-coating applications that responded to the Commission’s market investigation125 do not expect the Transaction to result in any price increases, reductions in quality or choice.126 The majority of these SB acrylic resins customers have indicated that a number of strategies would be available to them to respond to any increases of prices or decreases in volumes post-Transaction, including procuring adequate volumes of comparable quality and at comparable prices from alternatives suppliers in the EEA.127

(82) The majority of competing manufacturers of SB acrylic resins active in adjacent coating and non-coating applications that responded to the Commission’s market investigation128 similarly do not expect the Transaction to result in any price increases, reductions in quality or choice in any of the SB acrylic resins for any end- applications, including adjacent coating and non-coating applications.129

(83) The Commission accordingly considers that the Transaction does not raise serious doubts as to its compatibility with the internal market as a result of horizontal overlaps in the Parties’ activities in the possible EEA market for the supply of SB acrylic resins for adjacent coating and non-coating applications.

5.1.4.4.Supply of SB acrylic resin for other industrial applications

(84) As regards the market for the supply of SB acrylic resins for other industrial applications, the Transaction is unlikely to raise any competition concerns for the following reasons.

(85) First, the Parties’ combined market share is estimated to be [30-35]%, with an increment of [5-10]%.130

(86) Second, the market is fragmented, with many competitors remaining available as alternative suppliers post-Transaction, including Arkema (with an estimated market share of 20-25%), Dow (10-15%), Synres (5-10%), and a number of other competitors (e.g. Synthopol, Mitsubishi, DSM) representing about a quarter of the market (17-32%).131 Indeed, the vast majority of SB acrylic resins customers that responded to the Commission’s market investigation, including specifically those active in the other industrial applications segment, have stated that a sufficient number of suppliers of SB acrylic coating resins will remain in the EEA post-

Transaction.132

(87) Third, the vast majority of customers for SB acrylic resins for other industrial applications that responded to the Commission’s market investigation do not expect the Transaction to result in any price increases, reductions in quality or choice.133 The majority of these SB acrylic resins customers for other industrial applications have indicated that a number of strategies would be available to them to respond to any increases of prices or decreases in volumes post-Transaction, including procuring adequate volumes of comparable quality and at comparable prices from alternatives suppliers in the EEA.134

(88) All competing manufacturers active in SB acrylic resins for other industrial applications that responded to the Commission’s market investigation similarly do not expect the Transaction to result in any price increases, reductions in quality or choice in any of the SB acrylic resins for any end-applications, including other industrial applications.135

(89) The Commission accordingly considers that the Transaction does not raise serious doubts as to its compatibility with the internal market as a result of horizontal overlaps in the Parties’ activities in the possible EEA market for the supply of SB acrylic resins for other industrial applications.

5.1.5. Conclusion

(90) On the basis of the above considerations and the evidence collected during the market investigation, the Commission concludes that the Transaction does not raise serious doubts as to its compatibility with the internal market, because it is unlikely to give rise to horizontal non-coordinated effects in the markets for the supply of solvent-borne acrylic resins, both taken as a whole and for each of (i) marine, (ii) adjacent coating and non-coating, and (iii) other industrial applications.

5.2.Non-horizontal non-coordinated effects

5.2.1.Legal framework for the competitive assessment

(91) Mergers may involve vertical effects when concerning companies operating at different levels of the same supply chain. Pursuant to the Commission Guidelines on the assessment of non-horizontal mergers under the Council Regulation on the control of concentrations between undertakings (the “Non-Horizontal Merger Guidelines”),136 the analysis of the vertical effects of mergers does not entail the loss of direct competition between merging firms in the same relevant market and provide scope for efficiencies. However, there are circumstances in which vertical mergers may significantly impede effective competition. This is in particular the case if they give rise to foreclosure. 137

(92) The Non-Horizontal Merger Guidelines distinguish between two forms of foreclosure: input foreclosure, where the merger is likely to raise costs of downstream rivals by restricting their access to an important input, and customer foreclosure, where the merger is likely to foreclose upstream rivals by restricting their access to a sufficient customer base. 138

(93) Pursuant to the Non-Horizontal Merger Guidelines, input foreclosure arises where, post-merger, the merged entity would be likely to restrict its actual or potential rivals in the downstream market from having access to the products or services that the Parties would have otherwise supplied absent the merger, thereby raising its downstream rivals' costs by making it harder for them to obtain supplies of the input under similar prices and conditions as absent the merger. 139

(94) For input foreclosure to be a concern, the merged entity should have a significant degree of market power in the upstream market. Only when the merged entity has such a significant degree of market power, can it be expected that it will be able to significantly influence the conditions of competition in the upstream market and thus, possibly, the prices and supply conditions in the downstream market.140

(95) Pursuant to the Non-Horizontal Merger Guidelines, customer foreclosure may occur when a supplier integrates with an important customer in the downstream market and, because of this downstream presence, the merged entity may foreclose access to a sufficient customer base to its actual or potential rivals in the upstream market (the input market) and reduce their ability or incentive to compete which in turn, may raise downstream rivals' costs by making it harder for them to obtain supplies of the input under similar prices and conditions as absent the merger. This may allow the merged entity profitably to establish higher prices on the downstream market. 141

(96) For customer foreclosure to be a concern, a vertical merger must involve a company that is an important customer with a significant degree of market power in the downstream market. If, on the contrary, there is a sufficiently large customer base, at present or in the future, that is likely to turn to independent suppliers, the Commission is unlikely to raise competition concerns on that ground.142

(97) In its assessment, the Commission considers whether it is likely that the merged entity would engage in input or customer foreclosure strategies. In doing so, the Commission in principle analyses the merged entity's ability and incentives to engage in such foreclosure strategies, as well as the possible effects they may have on the relevant markets. Since these factors are intrinsically linked, they are often examined together.143

5.2.2.Market shares and overview of vertical relationships

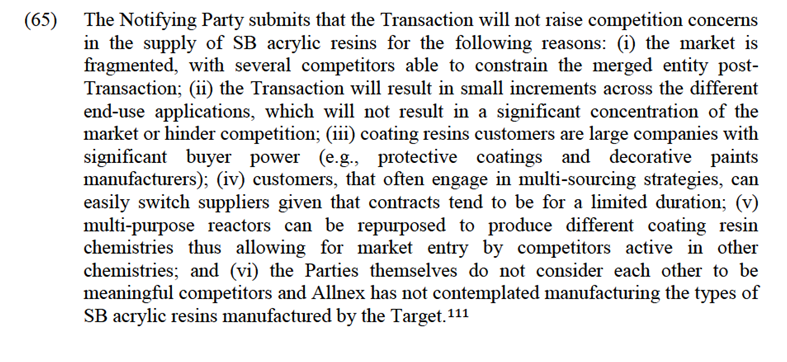

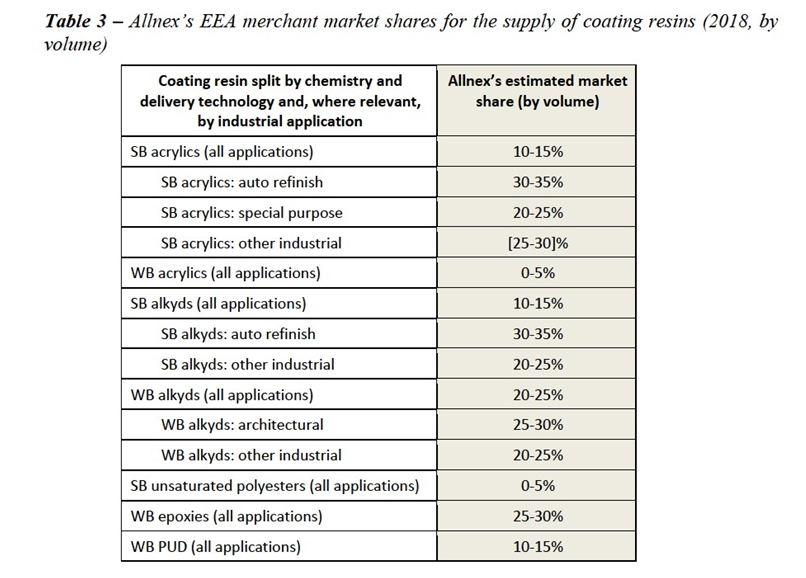

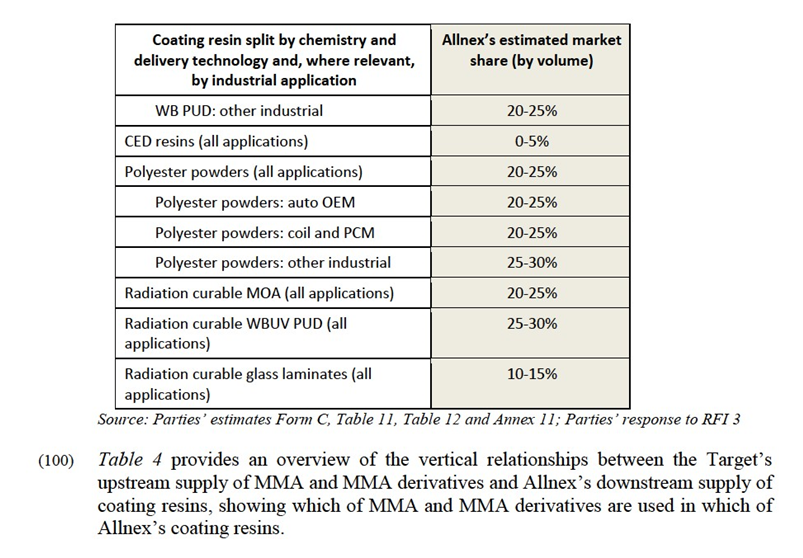

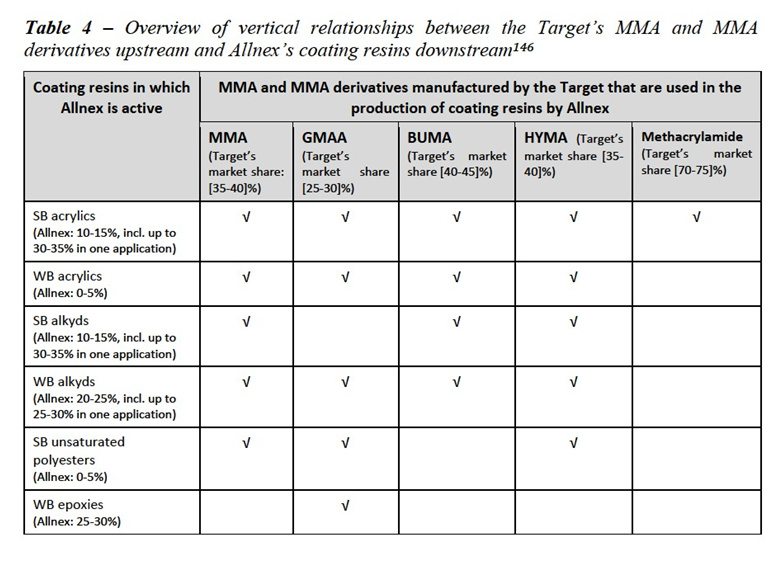

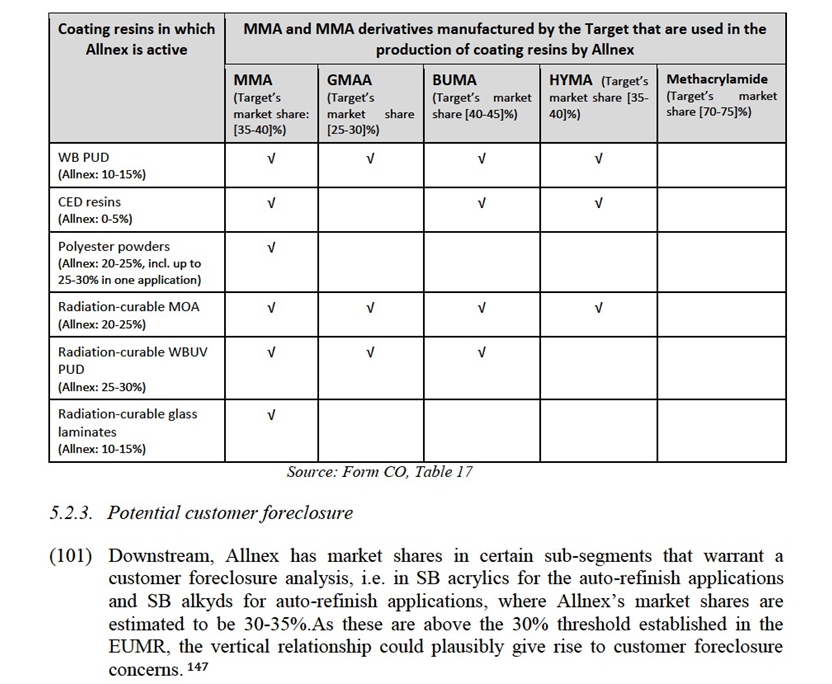

(98) Table 2 displays the market shares of the Target and its main competitors (based on the merchant market, excluding captive supplies) in the upstream supply of MMA and MMA derivatives.

38% of Western European demand for MMA),150 molding compounds, impact modifiers, and others. Indeed, the percentage of all MMA destined to the coating resins market in Western Europe is well below <25%,151 indicating that alternative customers remain available to MMA manufacturers. Thus, a theoretical customer foreclosure strategy would at most have a limited effect on the market. Given the lack of ability and the limited impact that such strategy would have on the market, the merged entity is unlikely to also have the incentive to do so as it is unlikely that any foreclosure strategy could be successfully implemented.

(104) In view of the above considerations supported by evidence collected during the market investigation, the merged entity appears unlikely to have the ability and incentive to implement a customer foreclosure strategy in the present case.

5.2.4.Potential input foreclosure

5.2.4.1.The Notifying Party’s views

(105) The Notifying Party submits that the merged entity would lack the ability and/or the incentive to foreclose its downstream rivals post-Transaction, and that even if it were to do so, such foreclosure would have very little effect on competition. First, in the Notifying Party’s view, MMA and MMA derivatives are simply an additive and not an essential input in the manufacture of most coating resins, such as SB/WB acrylics, SB/WB alkyds, polyurethanes and epoxy resins. Moreover, certain other coating resins do not generally make use of MMA or MMA derivatives at all, such as e.g. polyester powders or the majority of radiation-curable monomers. The Notifying Party highlights that even within coating resins of a certain chemistry category, MMA derivatives are not used for all end-use applications. The Notifying Party further argues that, in any event, when MMA and MMA derivatives are added to a resin, they represent a limited share of the total raw material cost for resin production, e.g. from 5-10% in WB PUDs up to 45-50% in polyester powders.

(106) Second, the Notifying Party submits that despite the Target’s EEA market shares being slightly above the 30% threshold for most MMA derivatives (with the exception of methacrylamide), the Target does not have a position of dominance in these markets. There are several other producers available, such as Lucite (all MMA derivatives, with the exception of methacrylamide), GEO and Nippon (HYMA), as well as other manufacturers with occasional spot sales of MMA derivatives in the market such as BASF or Dow. The Notifying Party also anticipates an expansion in the availability of MMA and MMA derivatives in the EEA with the increase of imports from China and Saudi Arabia.

(107) Third, in the opinion of the Notifying Party, given that the majority of coating resin manufacturers are active across a variety of coating resin chemistries and end-use applications, the merged entity could not successfully implement a foreclosure strategy targeted on the demand for certain resin chemistries and end-use applications (i.e., those produced by Allnex). This is because the merged entity would not have the ability to price differentiate for all the different uses for which a purchaser would be acquiring MMA derivatives. Thus, the merged entity would have to raise prices for its MMA derivatives regardless of the use by the purchaser, potentially leading to an irrecoverable decrease in upstream sales, and hence discouraging the recourse to such strategy in the first place.

(108) Fourth, the Notifying Party argues that even if the merged entity had the incentive to completely stop all sales to Allnex’s main competitors, the market would still have sufficient spare capacity to supply the vast majority of demand. This is true for MMA (Target sales to Allnex competitors: [Target’s volume of sales to Allnex’s competitors]; estimated EEA spare capacity [35-40]kt), GMAA (Target sales to Allnex competitors: [Target’s volume of sales to Allnex’s competitors]; estimated EEA spare capacity [5-10]kt), and HYMA (Target sales to Allnex competitors: [Target’s volume of sales to Allnex’s competitors]; estimated EEA spare capacity [5-10]kt).152 For BUMA, estimated EEA spare capacity would be slightly smaller than the Target’s current sales to Allnex’s competitors ([Target’s volume of sales to Allnex’s competitors]; spare capacity [5-10]kt), but the remaining [0-5]kt could be purchased from other regions, including through traders.

(109) Fifth, as concerns methacrylamide, the Notifying Party argues that it represents a very minor input to coating resins, representing a very small fraction of the total raw material costs for development of SB acrylic resins (i.e. <0.0001%), and that products using methacrylamide can be reformulated without incurring significant costs.

(110) Lastly, the Notifying Party submits that if the merged entity were to attempt an input foreclosure strategy, their customers (i.e. coating resin manufacturers) would be able to adjust and retaliate in order to make this option unattractive to the merged entity. As most customers generally purchase multiple MMA derivatives from the same upstream producer, any attempt to foreclose access to any given input would result in retaliation from the customers, who could stop purchasing other inputs. In addition, customers could easily replace MMA and MMA derivatives in their formulas and continue competing in the coating resins market without them within a reasonable timeframe. Moreover, as some major customers are integrated upstream into MMA or MMA derivatives (e.g. BASF, Arkema, Dow)153, any foreclosure strategy would have no effect on them as they would continue having access to the MMA derivatives from their own captive production.

5.2.4.2. The Commission’s assessment

(a) General results from the market investigation

(111) This section discusses the general results from the market investigation as regards the potential input foreclosure to downstream competitors. The competitive assessment of the vertical link between coating resins with each of MMA, GMAA, BUMA, HYMA and methacrylamide is presented in the subsequent sections.

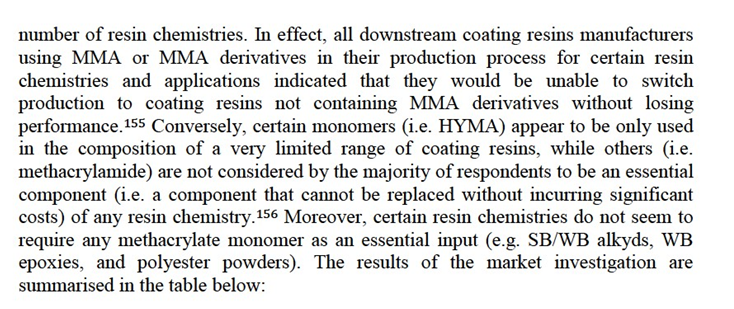

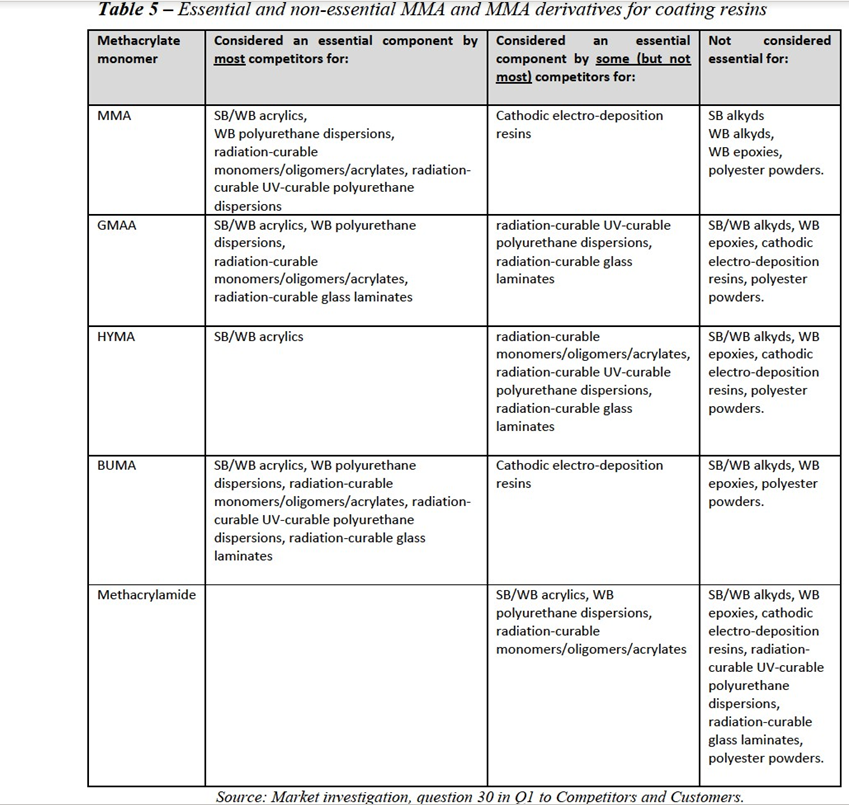

(112) Contrary to what is claimed in the Parties’ submissions, the Commission finds that the results of the market investigation suggest that MMA and some MMA derivatives (and, in particular, GMAA and BUMA) are essential154 for at least a

(113) The market investigation also confirmed that a significant number of competitors (7) are integrated upstream into the production of MMA and other methacrylate monomers, though some of them also resort to the merchant market for spot purchases of certain MMA derivatives.157 Nearly all downstream coating resins competitors engage in a multi-sourcing strategy, with many of them also making use of a wide array of traders to procure their requirements.158 The large majority of downstream competitors also purchase a variety of methacrylate monomer types from the Target159, thus confirming the Notifying Party’s claim.

(114) The market investigation further indicates that a very large proportion of downstream competitors appear to manufacture multiple coating resin chemistries and for multiple end-uses.160 Only a single competitor reported producing only one type of resin chemistry (WB acrylics),161 which is one in which Allnex does not have any significant presence as a competitor.162 Contrary to the Parties’ claims, a majority of downstream competitors stated that switching production lines to different coating resin chemistries and applications entails significant costs given the long and rigorous testing processes and the know-how required.163

(115) In terms of entry, the only significant newcomers into the MMA derivative markets in the EEA over the past 5 years were a number of producers with new production facilities outside of the EEA in Saudi Arabia (SABIC, Saudi Aramco), China, and Brazil (Unigel).164 In addition, Asian producers from China, Japan (Sumitomo) and Korea (LG) are expected to expand into the EEA at some point in the future.165

(116) Lastly, a large majority of downstream competitors indicated that the Transaction would have no impact on their business.166 In the SB acrylics segment (regardless of end-use application), where Allnex has larger market shares, the majority of downstream competitors stated that they did not expect the Transaction to bring about an increase in price, a drop in quality, or a reduction in customer choice.167 Moreover, whereas a majority of coating resin manufacturers suggested that shifting sourcing volumes might prove excessively costly in the short-to-medium term,168 these concerns related primarily to a hypothetical lack of availability in the EEA (i.e. due to temporary technical issues at the EEA-based suppliers’ manufacturing facilities) and not to the inability of a particular upstream manufacturer to supply their demand. In addition, the majority of downstream producers seems to expect that the market will remain long and that no major availability issues will arise in the medium term.169

(b) Input foreclosure MMA/coating resins

(117) According to the Notifying Party, the Target’s EEA market share in the MMA merchant market is [35-40]%, with the closest competitor Lucite having a slightly higher [35-40]%, and the remaining [20-25]% being held by a long tail of competitors (Arkema ([0-5]% - EU, US), Sumitomo ([0-5]% - Japan, Singapore, Saudi Arabia), Unigel (<5 – Brazil, Mexico), Asahi (<5% – Japan, Thailand), Jihua (<5% – China), Formosa Plastics (<5% – Taiwan), Sailboat (<5% – China), Shangdong Hongzu (<5% – China), Anda Longzing (<5% – China) and Kuraray (<5% – Japan)),170 many of whom supply EEA customers via traders. The market investigation confirmed these market positions, and indicated that there appears to be indeed a long tail of suppliers and traders available to customers in the coating resins market.171

(118) Moreover, the results of the market investigation reveal that MMA is considered to be an essential component for some but not all of the resin chemistries, namely: SB/WB acrylics, WB polyurethane dispersions, radiation-curable monomers/oligomers/acrylates, and radiation-curable UV-curable polyurethane dispersions.172 Conversely, the results of the market investigation also show that nearly all downstream coating resins competitors are active across multiple resin chemistries and industrial applications (including at least one category where MMA is an essential component).173 Consequently,174 any foreclosure attempt on the part of the merged entity could turn into a profit-losing strategy as it would have to cover virtually the whole range of downstream competitors in order to have any effect on the merged entity’s own market position in the downstream markets for coating resins.

(119) In addition, the ability of the merged entity to foreclose access to key inputs with a view to improving its downstream position would be further constrained by the fact that a significant number of downstream competitors are integrated upstream as regards the manufacture of MMA. Additionally, even when excluding these competitors from the analysis, in the extreme situation where the merged entity would completely stop selling MMA to Allnex’s competitors downstream, a conservative analysis of the results of the market investigation reveals that there would be sufficient spare capacity in the upstream market to cover over 95% of the EEA demand previously supplied by the Target to Allnex’s competitors.175 In support of this view, a large majority of the surveyed competitors expect that a sufficient number of alternative MMA suppliers with the required capacities will remain available in the market post-Transaction.176 As a result, it appears unlikely that the merged entity would have the ability to foreclose its downstream rivals.

(120) Likewise, it appears unlikely that the combined entity would have the incentives to engage in an input foreclosure strategy. This is notably because the market investigation has revealed that, on average, gross margins per tonne appear to be equal or higher for MMA than for most coating resin chemistries for which MMA is considered to be an essential input,177 which would discourage the expansion of the merged entity’s position downstream at the expense of its upstream sales. Moreover, the market investigation has confirmed that most customers purchasing MMA from the Target also purchase other MMA derivatives,178 which supports the Notifying Party’s argument that customers could punish the merged entity by discontinuing purchases of other MMA derivatives in case of attempt to foreclose the supply of MMA.

(121) In view of the above considerations supported by evidence collected over the course of the market investigation, the Commission considers that, after the Transaction, the merged entity is not likely to have the ability and incentive to foreclose its downstream rivals’ access to MMA.

(c) Input foreclosure GMAA/coating resins

(122) The results of the market investigation reveal that GMAA is considered to be an essential component for some but not all of the resin chemistries: SB/WB acrylics, WB polyurethane dispersions, radiation-curable monomers/oligomers/acrylates, and radiation-curable glass laminates.179 Conversely, the results of the market investigation also show that nearly all downstream competitors are active across multiple resin chemistries and end-use applications (including at least one category where GMAA is an essential component).180 Consequently,181 any foreclosure attempt on the part of the merged entity could turn into a profit-losing strategy as it would have to cover virtually the whole range of downstream competitors in order to have any effect on the merged entity’s own market position in the downstream markets for coating resins.

(123) In addition, the ability of the merged entity to foreclose their access to key inputs with a view to improving its downstream position would be further constrained by the fact that a significant amount of downstream competitors are integrated upstream as regards the manufacture of GMAA. Even, if these competitors were excluded from the analysis, the merged entity would still be unlikely to have the ability to foreclose its downstream rivals. The Target’s EEA market share in the GMAA merchant market is [25-30]%, with the closest competitors being Lucite (UK, [35- 40]%) and BASF (Germany, [20-25]%), and with a small market share held by Dow (USA, [5-10]%) and other manufacturers and traders both from within and outside the EEA (7%).182 Being one of three mid-to-large suppliers of GMAA in the EEA, the Target by itself is unlikely to have decisive influence over the availability of GMAA in the EEA. Moreover, the vast majority of downstream competitors using GMAA in their manufacturing process expect that a sufficient number of alternative GMAA suppliers with the required capacities will remain available in the market post-Transaction.183 As a result, it is unlikely that the merged entity would have the ability to foreclose its downstream rivals from access to necessary GMAA inputs.

(124) Likewise, it is unlikely that the merged entity would have the incentives to engage in an input foreclosure strategy. This is notably because the market investigation has revealed that, on average, gross margins per tonne appear to be higher for GMAA than for most coating resin chemistries for which GMAA is considered to be an essential input.184 This would discourage the expansion of the merged entity’s position downstream at the expense of its upstream sales. Moreover, the market investigation has confirmed that all customers purchasing GMAA from the Target surveyed also purchase other MMA derivatives from it,185 which supports the Notifying Party’s argument that customers could punish the merged entity by discontinuing purchases of other MMA derivatives in case of any attempt to foreclosure the supply of GMAA.

(125) In view of the above considerations supported by evidence collected during the market investigation, the Commission considers that, post Transaction, the merged entity is not likely to have the ability and incentive to foreclose its downstream rivals’ access to GMAA.

(d) Input foreclosure HYMA/coating resins

(126) The results of the market investigation reveal that HYMA is considered to be an essential component for two categories of resin chemistries, namely SB and WB acrylics. 186 Given that HYMA is only deemed essential for a small share of coating resin chemistries, the merged entity’s ability to foreclose its downstream rivals would be restricted to these two types of products and the overall impact of a hypothetical foreclosure strategy would accordingly be very limited.

(127) According to the Notifying Party, the Target’s EEA market share in the HYMA merchant market is [35-40]%, with the closest competitors being GEO (UK, [30- 35]%) and Nippon Shokubai (Japan, [20-25]%), and with small market shares held by Lucite (UK, [0-5]%) and by other manufacturers and traders both from within and outside the EEA (4%).187 In contrast, the market investigation suggested that GEO might instead be the largest supplier in the EEA.188 Being one of three mid-to- large suppliers of HYMA in the EEA, the Target by itself is unlikely to have decisive influence over the availability of HYMA in the EEA. Moreover, the ability of the merged entity to foreclose access to key inputs with a view to improving its downstream position would be further constrained by the fact that a significant number of downstream competitors are integrated upstream in the manufacture of HYMA. In addition, the large majority of the surveyed downstream competitors using HYMA expect that a sufficient number of alternative HYMA suppliers with the required capacities will remain available in the market post-Transaction.189 As a result, it appears unlikely that the merged entity would have the ability to foreclose its downstream rivals.

(128) Likewise, it appears unlikely that the merged entity would have the incentive to engage in an input foreclosure strategy in relation to HYMA. This is notably because, on average, gross margins per tonne appear to be equal or higher for HYMA than for most coating resin chemistries for which HYMA is considered to be an essential input.190 This would discourage the expansion of the merged entity’s position downstream at the expense of its upstream sales. Additionally, the market investigation has confirmed that all customers purchasing HYMA from the Target also purchase other MMA derivatives from it (and generally in higher quantities),191 which supports the Notifying Party’s argument that customers could punish the merged entity by discontinuing purchases of other MMA derivatives in case of any attempt to foreclose the supply of HYMA.

(129) In view of the above considerations supported by evidence collected during the market investigation, the Commission considers that, post Transaction, the merged entity is not likely to have the ability and the incentive to foreclose its downstream rivals’ access to HYMA.

(e) Input foreclosure BUMA/coating resins

(130) The results of the market investigation reveal that BUMA is considered to be an essential component for some but not all of the categories of resin chemistries: SB/WB acrylics, WB polyurethane dispersions, radiation-curable monomers/oligomers/acrylates, radiation-curable UV-curable polyurethane dispersions, radiation-curable glass laminates.192 Conversely, the results of the market investigation also show that nearly all downstream competitors are active across multiple resin chemistries and end-use applications (including at least one category where BUMA is an essential component).193 Consequently,194 any foreclosure attempt on the part of the merged entity could turn into a profit-losing strategy as it would have to cover virtually the whole range of downstream competitors in order to have any effect on the merged entity’s own market position in the downstream markets for coating resins.

(131) The Target’s EEA market shares in the BUMA merchant market are [40-45]%, with the closest competitor being Lucite (UK, [35-40]%), and with small market shares held by Dow (USA, [5-10]%) and other manufacturers both from within and outside the EEA (16%).195 Despite this market share, the ability of the merged entity to foreclose access to key inputs would be constrained by the fact that a significant number of downstream competitors are integrated upstream as regards the manufacture of BUMA. Moreover, the large majority of the surveyed downstream competitors expect that a sufficient number of alternative suppliers for BUMA with the required capacities will remain available post-Transaction.196 As a result, it appears unlikely that the merged entity would have the ability to foreclose its downstream rivals.

(132) Likewise, it appears unlikely that the merged entity would have the incentive to engage in an input foreclosure strategy. This is notably because, on average, gross margins per tonne appear to be higher for BUMA than for the largest resin chemistry markets for which BUMA is considered to be an essential input,197 which would discourage the expansion of the merged entity’s position downstream at the expense of its upstream sales. Additionally, the market investigation has confirmed that all customers purchasing BUMA from the Target also purchase other MMA derivatives from it (and generally in higher quantities),198 which supports the Notifying Party’s argument that customers could punish the merged entity by discontinuing purchases of other MMA derivatives in case of attempt to foreclose the supply of BUMA.

(133) In view of the above considerations supported by evidence collected over during the market investigation, the Commission concludes that, post Transaction, the merged entity is not likely to have the ability and incentive to foreclose its downstream rivals’ access to BUMA.

(f) Input foreclosure methacrylamide/coating resins

(134) The results of the market investigation reveal that methacrylamide is not considered to be an essential component for any of the categories of resin chemistries.199 In particular, the vast majority of downstream competitors indicated that they could replace methacrylamide without incurring significant costs.200 Hence, there appears to be very limited ability to engage into a foreclosure strategy in relation to methacrylamide. Moreover, the small minority of surveyed competitors who indicated that switching could entail significant costs are active in markets where Allnex does not have a strong presence (e.g. in WB acrylics, where Allnex has a 0- 5% market share, or in WB PUDs, where Allnex has a 10-15% market share),201 thereby casting doubt on the merged entity’s incentive to engage in any foreclosure strategy vis-à-vis these competitors.

(135) In addition, as a significant amount of downstream competitors are integrated upstream in the manufacture of MMA derivatives, including methacrylamide, the merged entity would in any event be deprived of the ability to foreclose their access to key inputs. Overall, only a small minority of downstream competitors consider that they could face a shortage of methacrylamide in the EEA post-Transaction,202 and that shortage is unlikely to originate from the conduct of the merged entity.203

(136) In view of the above considerations supported by evidence collected during the market investigation, the Commission concludes that, after the Transaction, the merged entity is not likely to have the ability and incentive to foreclose its downstream rivals’ access to methacrylamide.

5.2.5.Conclusion

(137) Taking into consideration the assessments carried out in sections 5.2.2 to 5.2.4 above, it appears unlikely that the merged entity would have the ability and the incentive to foreclose its competitors in the upstream markets for MMA and MMA derivatives from their access to an important customer or to foreclose its rivals in the downstream markets for coating resins from their access to key inputs (MMA and MMA derivatives).

6. CONCLUSION

(138) For the above reasons, the European Commission has decided not to oppose the notified operation and to declare it compatible with the internal market and with the EEA Agreement. This decision is adopted in application of Article 6(1)(b) of the Merger Regulation and Article 57 of the EEA Agreement.

1 OJ L 24, 29.1.2004, p. 1 (the 'Merger Regulation'). With effect from 1 December 2009, the Treaty on the Functioning of the European Union ('TFEU') has introduced certain changes, such as the replacement of 'Community' by 'Union' and 'common market' by 'internal market'. The terminology of the TFEU will be used throughout this decision.

2 OJ L 1, 3.1.1994, p. 3 (the 'EEA Agreement').

3 Publication in the Official Journal of the European Union No C 186, 3.6.2019, p. 20.

4 Form CO, paragraph 93. See also paragraphs (8)-(9) below.

5 Turnover calculated in accordance with Article 5 of the Merger Regulation.

6 The acquisition of Nuplex Industries by Advent was reviewed and authorised by the European Commission in Case M.8019 – Advent International/Nuplex Industries.

7 Form CO, paragraphs 41, 43, 52; Case M.6778 – Advent International Corporation/Cytec’s Resin Business; Case M.8019 – Advent International/Nuplex Industries.

8 Form CO, paragraph 91.

9 Form CO, paragraph 92.

10 Form CO, paragraph 93.

11 Form CO, paragraph 94; Commission decision in Case M.9019 – Advent International/Nuplex Industries, paragraph 30; Form CO, paragraph 9 and footnote 62.

12 Form CO, paragraph 52.

13 Form CO, paragraph 2.

14 IHS Chemical “Methyl Methacrylate Chemical Economics Handbook” (15 August 2016), provided as Annex 8 to the Form CO, p.5.

15 Form CO, paragraph 2.

16 Form CO, paragraph 2.

17 IHS Chemical “Methyl Methacrylate Chemical Economics Handbook” (15 August 2016), provided as Annex 8 to the Form CO, p.71.

18 IHS Chemical “Methyl Methacrylate Chemical Economics Handbook” (15 August 2016), provided as Annex 8 to the Form CO, p.74.

19 IHS Chemical “Methyl Methacrylate Chemical Economics Handbook” (15 August 2016), provided as Annex 8 to the Form CO, p.74.

20 Form CO, Table 24.

21 Information on hydroxyesters on the Target’s website: https://methyl-methacrylate- monomers.evonik.com/product/visiomer/en/products/CHEMICAL-FUNCTIONALITIES/.

22 Form CO, Table 24; Product information for the Target’s 2-hydroxyethyl methacrylate: http://www.neochemical.ru/File/TDS Visiomer HEMA 98.pdf and http://www13.evonik.com/bk2/product finder/evonik productDetail.asp?padding=on&aktProdID=32 62.

23 Form CO, Table 24; Product information for the Target’s hydroxypropyl methacrylate: http://www13.evonik.com/bk2/product finder/evonik productDetail.asp?padding=on&aktProdID=32 64.