Commission, January 8, 2021, No M.9981

EUROPEAN COMMISSION

Decision

BAIN CAPITAL / AHLSTROM-MUNKSJÖ

Subject: Case M.9981 – Bain Capital/Ahlstrom-Munksjö

Commission decision pursuant to Article 6(1)(b) of Council Regulation No 139/20041 and Article 57 of the Agreement on the European Economic Area2

Dear Sir or Madam,

(1) On 25 November 2020, the European Commission received notification of a proposed concentration pursuant to Article 4 of the Merger Regulation by which Bain Capital Investors L.L.C. (“Bain Capital” or the “Notifying Party”) intends to acquire sole control of Ahlstrom-Munksjö Oyj (together with its subsidiaries, “Ahlstrom-Munksjö” or the “Target”), by way of purchase of shares (the “Transaction”).3 In this Decision, Bain Capital and the Target are collectively referred to as the “Parties”.

1. THE PARTIES

(2) Bain Capital is a private equity investment firm that invests, through its family of funds, in companies across a number of industries, including information technology, healthcare, retail and consumer products, communications, financial services and industrial/manufacturing.

(3) Ahlstrom-Munksjö is a global manufacturer and supplier of fibre-based materials. Its product offering includes, inter alia, filter materials, release liners, food and beverage, processing materials, décor papers, abrasive and tape backings, electro- technical paper, glass fibre materials, medical fibre materials and solutions for diagnostics as well as a range of specialty papers for industrial and consumer end- uses.

2. THE OPERATION

(4) The Transaction concerns the acquisition of all of the outstanding issued share capital of Ahlstrom-Munksjö, which is currently publicly listed on the Nasdaq Helsinki and Nasdaq Stockholm exchanges, by funds managed by Bain Capital, in partnership with Ahlstrom Invest B.V., Viknum AB and Belgrano Inversiones Oy (together, the “Lead Family Investors”).

(5) Following the proposed Transaction, Bain Capital will hold 55% of the ordinary shares of the Target, while the Lead Family Investors will own 45%.

(6) None of the Lead Family Investors will, collectively or individually, acquire control over Ahlstrom-Munksjö within the meaning of the EU Merger Regulation. The board of the Target will comprise of […] voting members, […] of which appointed by Bain Capital and […] by the Lead Family investors. The Board will vote by […] save for certain reserved matters, which provide for customary protection of minority shareholders’ interests and do not allow to veto any strategic decision of the Target such as its business plan or its budget.

3. THE CONCENTRATION

(7) After the Transaction, Ahlstrom-Munksjö, will be solely controlled by Bain Capital within the meaning of Article 3(1)(b) of the EU Merger Regulation.

4. EU DIMENSION

(8) The undertakings concerned have a combined aggregate worldwide turnover of more than EUR 5,000 million (Bain Capital: EUR […]; Ahlstrom-Munksjö: EUR […])4. Each of them has an EU-wide turnover in excess of EUR 250 million (Bain Capital: EUR […]; Ahlstrom-Munksjö: EUR […]) and they do not achieve more than two-thirds of their aggregate EU-wide turnover within one and the same Member State. The notified operation therefore has an EU dimension pursuant to Article 1(2) of the EU Merger Regulation.

5. MARKET DEFINITION

(9) Bain Capital has one existing controlled investment, Fedrigoni S.P.A. (“Fedrigoni”), which has some activities that overlap with, or are vertically related to, those of Ahlstrom-Munksjö. Fedrigoni is an Italian company active in the manufacturing and supply of various types of paper, including graphic and fine paper, security paper and solutions, self-adhesive label stock (“SAL”) and stationery.

(10) The only relationship between Fedrigoni and Ahlstrom-Munksjö giving rise to affected markets relates to a vertical link as regards the production and supply of release liners by Ahlstrom-Munksjö (upstream) for use in the production and supply of SAL5 by Fedrigoni (downstream). 6

5.1. Product market definition

5.1.1. The production and supply of release liners

(11) Release liners (also called release base papers) are surface-treated specialty papers used as release carrier and backing webs for a wide range of self-adhesive products, including labels, graphic arts (e.g. for printed graphic face stock), industrial applications (e.g. casting sheets, industrial processing sheets), envelopes (to cover the self-adhesive strips of postal envelopes and mailing bags), tapes (e.g. as carrier for supported and unsupported adhesives) and medical (e.g. for medical dressings and tapes) and hygiene products.

(12) Release liners are typically coated with silicone to provide low surface energy to the paper, which allows the pressure sensitive adhesives to release from the liner with a constant force. The main properties of release liners include smoothness, high strength, low porosity, sealed surface, dimensional stability and compatibility with different silicone systems. The surface finish can be (super-) calendered7, coated, or similar.

(13) All release liners are produced using similar production processes. The main step is to siliconise the surface of the substrate with either solventless, solvent or emulsion silicones. Following siliconisation, lines are cured, using either a thermal or a radiation curing technique.

(14) Release liners can be paper-based or film-based8:

(a) Paper-based release liners:

– Glassine release liners/Supercalendered Kraft (“SCK”) are supercalendered in a stack of 16-18 rolls, resulting in a dense, smooth and translucent paper.9 They are predominantly used in SAL but are also used for tapes and in industrial applications.

– Clay coated kraft (“CCK”) release liners have a paper surface that is closed with mineral coating to control the silicone uptake. Typical CCK applications include graphics and office.

– Polyolefin Film Coated release liners (“Poly-Coated Kraft” or “PCK”) are liners where a molten web of polymer is extruded on to paper either on one or both surfaces. They are paper-based release liners on which a film material is extruded, thus being a hybrid between paper and film. Typical applications include SAL, self- adhesive graphics, and applications for the construction industry.

– Other release liners include machine finished (“MF”) and machine glazed (“MG”) kraft papers, pre-coated or latex saturated and other specialty grades that do not fit the categories described above. Typical applications for these types of release liners include hygiene and niche applications.

(b) Film- based release liners are coated with polyester (“PET”), polypropylene (“PP”) or polyethylene (“PE”) films. Typical applications for films release liners include SAL with transparent film facestock (no label look), film facestock applied in a wet environment and release liners used in hygiene and medical applications, as well as electronic and other industrial applications.

(15) Ahlstrom-Munksjö does not manufacture or supply film-based release liners. It only produces glassine and CCK release liners in its production mills in […]. Fedrigoni produces only a negligible volume of glassine release liners in the EEA10 (approximately […] in 2019) and exclusively for internal consumption, not for sale to third parties.

(16) The Commission has considered release liners on a number of occasions and has ultimately left open the question of whether all types of release liners belong to the same relevant product market or whether they should be segmented by substrate (namely film-based and paper-based release liners).11

(17) The Notifying Party submits that all types of release liners belong to the same relevant product market since (i) customers can and do partially substitute film-based release liners for paper-based release liners and (ii) most manufacturers can produce release liners for a number of different applications and can work with different substrates.

Film-based versus paper-based release liners

(18) The market investigation carried out by the Commission indicated that film-based and paper-based release liners are not substitutable from the supply-side perspective. Only two competitors, responding to the market investigation indicated that they produce both film-based and paper-based release liners. Even one of the respondents that produce both types of release liners submitted that it is “difficult to switch from film to paper and vice versa”.12 Other respondents indicated that “papermaking equipment can’t be suited for filmic/plastic material production and vice versa”13, that “companies typically focus on either paper or film, not both”, and that “for substrate providers (like paper manufacturer or film manufacturer), they could only provide one type of release liners separately”.14 In line with the Notifying Party’s argument, another respondent indicated that “film based release liner can, and has substituted, particularly glassine type release liner in many end uses. However, also paper based release liners have replaced film based release liners depending on the Customer’s choice.”15

(19) As regards the demand-side substitutability, the results of the market investigation were mixed. Competitors said that “film based release liner can, and has substituted, particularly glassine type release liner in many end uses”. One customer of release liners indicated that it would switch its purchases from film-based to paper-based release liners in case of a price increase of the former “depending on market situation and end-user preferences”.16 Another respondent explained that “paper based and film based release liners have different applications”.17

(20) For the purposes of this decision, the Commission considers that it can be left open whether paper-based and film-based release liners belong to separate product markets, as the Transaction does not raise any competition concerns, irrespective of the exact market definition adopted. As Ahlstrom-Munksjö does not produce film- based release liners (see paragraph (15)), this decision looks only at paper-based release liners.

Possible distinction within different types of paper-based release liners

(21) The results of the market investigation were also mixed with regard to whether the market for the production and supply of paper-based release liners should be segmented by type (i.e., glassine, CCK, other). Ahlstrom-Munksjö only produces glassine and CCK release liners.

(22) From the supply side perspective, several release liners suppliers responding to the market investigation indicated that they produced several types of paper-based release liners.18 Another respondent submitted that “technically, switching from one base paper to another one is impossible in some application (silicone 2 sides for tapes for example). Still there is some room for changes in some other application (function of the release liner should be more important than the habits)”.19

(23) As regards demand-side substitutability, one competitor said that “[they are substitutable] to a certain extent by making specific process adjustment”.20 Another competitor said that “there are segments which are overlapping or substitutable by the other but not each of them by all others.”21

(24) The majority22 of the customers who replied to the market investigation indicated that release liners should be segmented between Glassine Release Liners, CCK Release Liners, PCK release liners, Film release liners23 and that there are specific end use applications which require the use of a specific type of release liner.24 One customer indicated that “SCK, CCK, PCK, film release liners differ in terms of price and application”.25

(25) For the purposes of this decision, the Commission considers that it can be left open whether different types of paper-based release liners belong to separate product markets, as the Transaction does not raise any competition concerns, irrespective of the exact market definition adopted. For the purpose of this decision, the assessment will look at both the market for paper-based release liners (as Ahlstrom-Munksjö does not produce film-based release liners) and then specifically at the plausible segment of glassine release liners alone.26

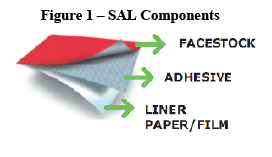

5.1.2. The production and supply of SAL

(26) SAL is paper or film (i.e. synthetic material) pre-coated with a pressure-activated adhesive and protected by a backing material or paper. SAL is used in a number of different products, e.g. price tags, product information, functional, security and promotional labels. Labels are used in turn in various industries, such as logistics and retail, food and beverage, non-food consumer goods including household and personal care products, durables/automotive, chemicals, pharmaceuticals, construction, office products, visual communications and others.

(27) SAL consists of the following components: (i) the face material, also called facestock, is the part that remains visible on which text and/or decoration is printed; (ii) the adhesive, which is used to make the paper adhere to the surface being labelled; (iii) the base material, also called release liner, which protects the adhesive and which is covered by a silicone layer allowing an easy release.

(28) SAL is manufactured in rolls (also called reels), generally with a width of 100-200 cm, which are then cut/slit in two forms: (i) sheets cut in primarily standardised sizes are normally purchased by merchants, who resell the SAL to their customers as part of a wide range of other products; (ii) narrow rolls are cut according to customer specifications and are accordingly subject to one or more additional converting steps as compared to sheets. SAL is used in a myriad of end applications, such as graphic arts, tapes, hygiene, medical, envelopes, industrial or other, and manufacturers of SAL typically cover a wide range of end applications.27

(29) Fedrigoni’s Pressure Sensitive Labels business unit manufactures and supplies paper-based and film-based SAL for a range of applications, including for the food and wine, pharmaceuticals, visual communications and publishing industries as well as for various industrial applications. Fedrigoni manufactures and distributes pressure sensitive labels through its subsidiaries Arconvert and Manter, with locations in both Italy and Brazil, together with subsidiary Ritrama (acquired in January 2020), which has manufacturing facilities and logistics centres in Italy, Spain, the UK, the US, Chile and China.

(30) The Commission has previously considered whether (i) film-based and paper-based SAL and (ii) SAL sold in reels and SAL sold in sheets could be distinct markets but ultimately left the question open.28 The Commission has also previously considered that, while alternatives to SAL (such as labels that are fixed on the basis of gum, labels fixed by glue activated by heat, wet-glue labels, sleeves, in-mould labels and direct printing) may to some extent be substitutable with SAL on the demand-side, they are not to be regarded as forming part of the same relevant product market.29

(31) The Notifying Party submits that all SAL, irrespective of the substrate material (film or paper) or form (sheets or reels), is part of the same relevant product market based mainly on supply-side substitution considerations. According to the Notifying Party, from the demand-side, the bulk of the demand (approx. […]%) is addressed through standard, commoditised SAL which is used in a variety of applications without any significant variation in the production process and, therefore, any SAL supplier can cater for this demand, by simply adjusting the configuration of the machines. According to the Notifying Party, only the remaining […]% of the demand concerns applications with higher technical requirements (for instance high strength or heat or chemicals resistance) required for use in adverse conditions such as in the durables/automotive, pharmaceuticals (requiring pasteurisation) and chemicals sectors, or in the food and beverage sector, which may require specific productive assets, which can however be acquired by any SAL supplier without incurring significant investments. Nonetheless, for the purposes of the Transaction, the Notifying Party submits that the exact product market definition can be left open, as the Transaction would not raise concerns under any plausible product market definition.30

Film-based and paper-based SAL

(32) The results of the market investigation were inconclusive as to whether film-based and paper-based SAL belong to separate product markets.

(33) From a demand-side perspective, half of the respondents to the Questionnaire for SAL suppliers and 60% of respondents to the Questionnaire for SAL customers considered that they are not substitutable, while the others considered that they are.31 To illustrate this, one SAL customer explained that “[t]he application window and the intended application of paper and film-based products are completely different in terms of technical properties, application requirements, design and functionality” while another one considered them to be substitutable based on supply-side considerations as “[t]he high level of quality shown by the suppliers provides the advantage of changing according to the most favorable interests of the client”.32 A SAL supplier explained that they are not substitutable under the consideration that “[p]aper-based SAL are generally less durable and lower priced than film-based SAL. A highly durable industrial application would generally not use a paper-based SAL”, while another one considered that “[p]aper and film based labelstock can be used in the same end use segments and are somewhat interchangeable in terms of technical characteristics (they perform the same). Commercial differences are rather small”.33

(34) From a supply-side perspective, the majority of the SAL manufacturers responding to the Commission investigation produce SAL based on any substrate.34 Those who do not produce SAL based on any given substrate claim to face significant barriers to switch the production of SAL based on different substrates.35 At the same time, all36 of the respondents to the Questionnaire for SAL suppliers and the majority of the respondents to the Questionnaire for SAL customers considered that manufacturers of SAL generally cover a wide-range of SAL products with regard to the substrates (paper-based or film-based) used in the production process, including Arconvert/Ritrama (both brands of Fedrigoni), Avery Dennison, CCL, Flexcon, Frimpex, Intercoat, Lintec, Mactac, UPM Rafaltac, VPF, Torras Papel and 3M.37

(35) For the purposes of this decision, the Commission considers that it can be left open whether paper-based and film-based SAL belong to separate product markets, as the Transaction does not raise any competition concerns, irrespective of the exact market definition adopted.

SAL sold in reels and SAL sold in sheets

(36) The results of the market investigation were inconclusive as to whether SAL sold in reels and SAL sold in sheets belong to separate product markets.

(37) From a demand-side perspective, all of the respondents to the Questionnaire for SAL suppliers and the majority of the respondents to the Questionnaire for SAL customers considered that SAL sold in reels and SAL sold in sheets are not substitutable.38 According to one supplier of SAL “SAL in sheets usually have a higher price due to a thicker liner for layflat applications and are intended often for screen printing. SAL in rolls have various liners and can be used in various types of printed applications”39. One customer of SAL explained that “[t]he technical properties and intended product application of reels vs. sheets regularly differ according to technology, technical material properties, production assets and end- use application”.40

(38) From a supply-side perspective, the majority of the SAL manufacturers responding to the Commission investigation produce SAL in different forms (i.e. in reels and in sheets) and some of those who do not produce SAL in different forms claim to face significant barriers to switch the production of SAL based on different forms.41 At the same time, all of the respondents to the Questionnaire for SAL suppliers and the majority of the respondents to the Questionnaire for SAL customers considered that manufacturers of SAL generally cover a wide-range of SAL products with regard to the SAL’s form (i.e. in reels or in sheets), including Avery Dennison, Intercoat, Raflatac, Scandstick, Smith and Mc Lauren, UPM and Torras Papel.42

(39) For the purposes of this decision, the Commission considers that it can be left open whether SAL sold in reels and SAL sold in sheets belong to separate product markets, as the Transaction does not raise any competition concerns, irrespective of the exact market definition adopted.

5.2. Geographic market definition

5.2.1. The production and supply of release liners

(40) The Commission has previously considered that the geographic market for the supply of release liners is at least EEA-wide, ultimately leaving the exact geographic market definition open.43

(41) The Notifying Party submits that the market for the supply of release liners is at least EEA-wide because (i) release liners producers supply across the EEA and beyond regardless of their mills’ location; (ii) customers source release liners from different countries across the EEA notwithstanding their own plants’ location; (iii) transport costs are low; and (iv) prices are generally consistent across the EEA.

(42) The vast majority of the release liners suppliers who responded to the market investigation indicated that they supply customers worldwide.44 Release liners suppliers submitted that although transportation costs are not insignificant (accounting for around 5-10% of the price), those do not appear to constrain cross- border trade.45

(43) As regards differences in prices, according to the Notifying Party’s submissions, it appears that release liner prices are generally consistent across Member States.46 The results of the market investigation revealed, however, that prices may differ between the EEA and other parts of the world.47

(44) The vast majority of the customers who replied to the market investigation confirmed that they purchase from any supplier worldwide48 and that they would switch to suppliers located at a further distance should their current supplier increase its prices.49 They all invite manufacturers of release liners located outside the EEA to participate in the procurement procedures for their plants located in the EEA.50

(45) The Commission considers that the question of whether the geographic scope of the market for the manufacture and supply of release liners (and any plausible sub segmentation) is EEA-wide or global may be left open for the purposes of this decision as it does not alter the conclusions of the competitive assessment. However, the Commission has carried out the competitive assessment on the basis of the narrowest plausible geographic market, that is, an EEA-wide market.

5.2.2. The production and supply of SAL

(46) In its prior decisions, the Commission considered that the geographic market for the manufacturing and supply of SAL is at least EEA-wide.51

(47) The Notifying Party agrees with the Commission’s precedent and considers that geographic markets for SAL narrower than the EEA-wide are not plausible and that for large customers the geographic scope of the market is global. According to the Notifying Party, the market is at least EEA-wide in scope because suppliers located in different Member States do not face any impediment to commercialising their sales throughout and beyond the EEA. The Notifying Party notes that this was confirmed in the Commission’s market investigation in Case M.2867, UPM- Kymmene Corporation/Morgan Adhesives Company. The Notifying Party submits that the fact that the market is at least EEA-wide is sustained by the fact that (i) there is a significant cross-border flow of products between Member States and with third countries; (ii) none of the market players has a local presence in every country where they operate; (iii) the distribution network needed to penetrate and serve a market is easy to set up.52

(48) The majority of the respondents to the Questionnaire for SAL suppliers stated that they manufacture for any customer worldwide and the majority of the respondents to the Questionnaire for SAL customers stated that they purchase from any supplier worldwide.53 According to one customer “[w]e can’t distinguish on regional areas as supplying site is determined by suppliers technical capabilities. There are suppliers in Germany, United Kingdom, France, Italy, Spain and many other countries supplying our different locations in Italy, Germany etc.”54 A supplier also explained that “[o]ur customers are located in both in EEA but also worldwide (smaller part)”.55 The majority of respondents to the Questionnaire for SAL suppliers and respondents to the Questionnaire for SAL customers stated that the prices for SAL in different parts of the world (e.g. Europe, Asia, Latin America, North America, the Middle East) do not differ to an appreciable extent.56 One supplier explained that “[w]hile freight and transport costs are not insignificant, these costs are not a constraint on trade within the EEA”.57

(49) A minority of suppliers and customers stated that the scope of their sales / purchases of SAL was within a given distance of their EEA facilities, e.g. one supplier stated that “[w]e deliver SAL mainly to polish and european market”58 and one customer stated that “[a]ll our suppliers have and use the factories at their convenience […], then the production of materials is done where they have factories (CEE) and in each country they usually have conditioning and cutting centers, from where they re- […]ship the material we have bought from them”.59 None of the respondents considered the market to be national in scope.

(50) For the purposes of this decision, the Commission considers that the question whether the geographic scope of the market for the manufacture and sale of SAL is EEA-wide or global may be left open for the purposes of this decision, as it does not alter the conclusions of the competitive assessment. However, the Commission has carried out the competitive assessment on the basis of the narrowest plausible geographic market, that is, an EEA-wide market.

6. COMPETITIVE ASSESSMENT

(51) The Transaction gives rise to vertically affected markets between the manufacture and sale of release liners by Ahlstrom-Munksjö (upstream) and the manufacture and sale of SAL by Fedrigoni (downstream).60

6.1. Market Shares

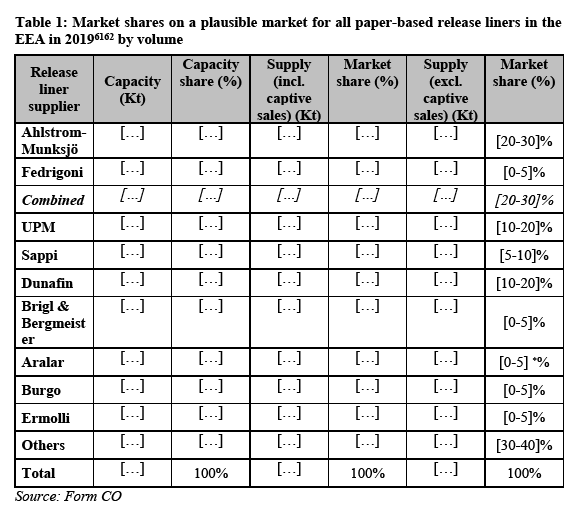

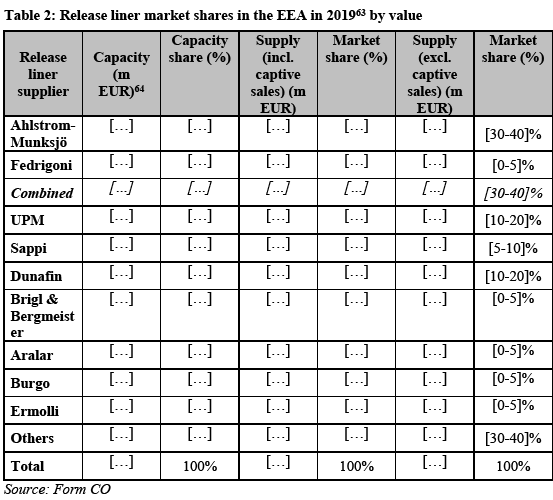

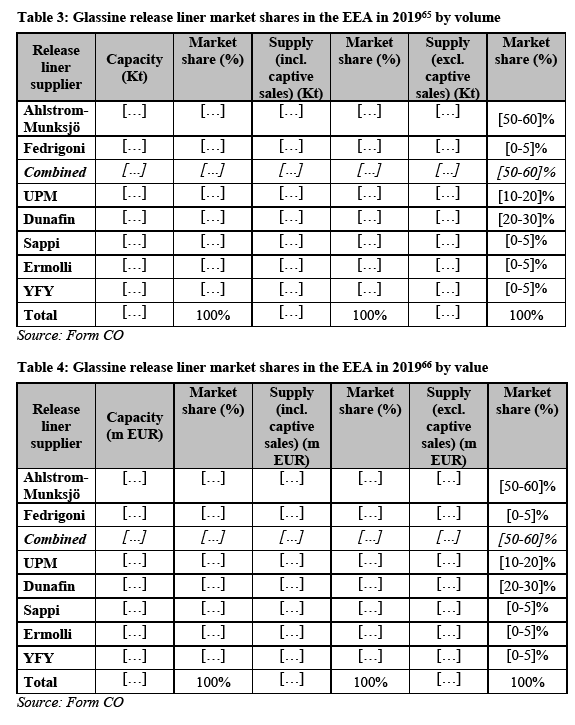

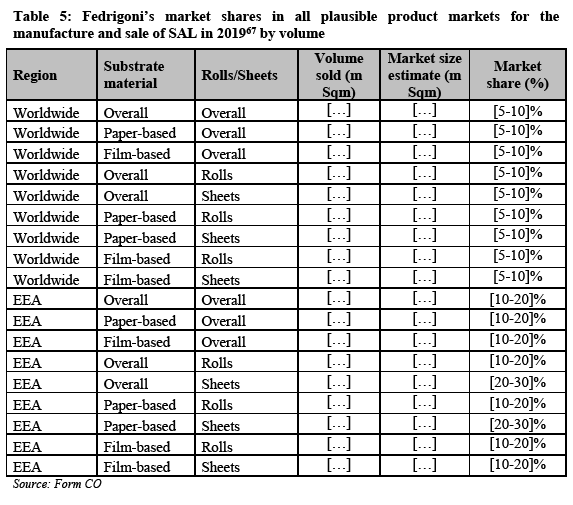

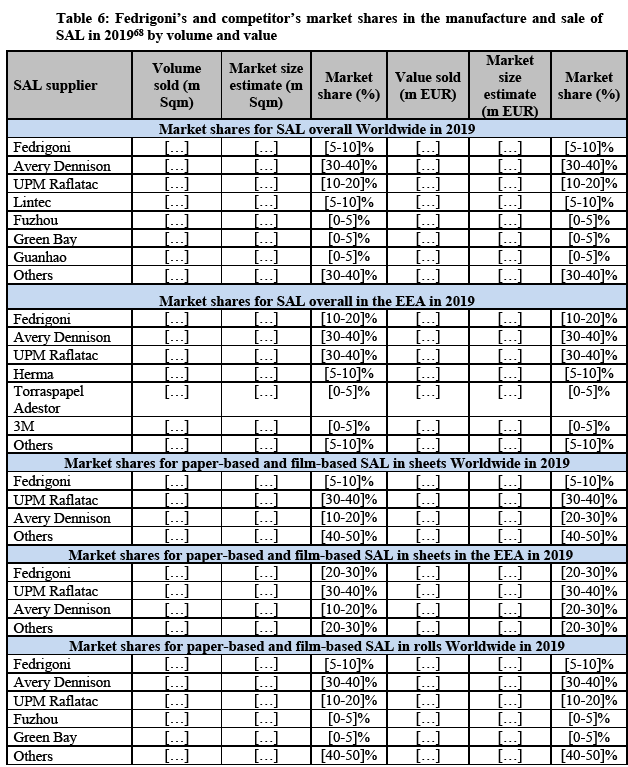

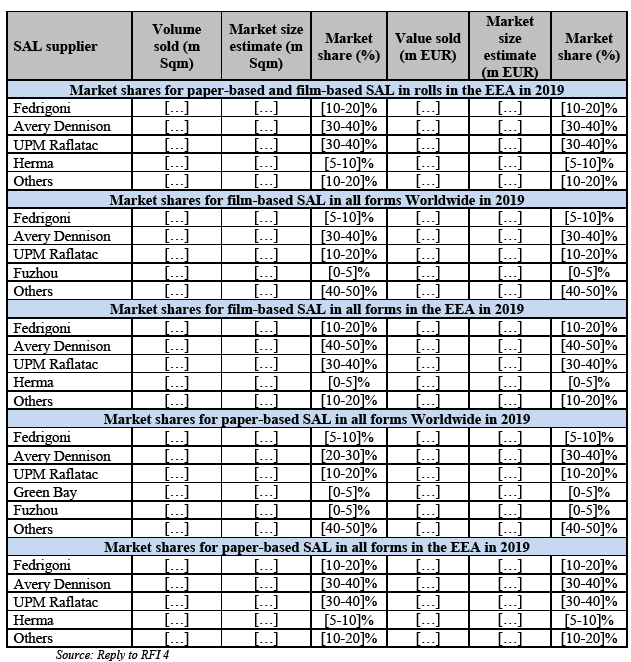

(52) The tables below illustrate the market shares of the Parties in each of the vertically affected markets.

6.2. Analytical framework

(53) As regards non-horizontal effects, the Commission Guidelines on the assessment of non-horizontal mergers,69 (“Non-Horizontal Merger Guidelines”) distinguish between two broad types of concentrations that concern undertakings which are active on different relevant markets (“non-horizontal mergers”), namely vertical mergers and conglomerate mergers.

(54) A vertical merger may result in anti-competitive effects due to foreclosure. Foreclosure concerns a situation where actual or potential rivals’ access to supplies or markets is hampered or eliminated as a result of the vertical merger, thereby reducing these companies’ ability and/or incentive to compete.70 Two forms of foreclosure can be distinguished in a vertical relationship: input and customer foreclosure.

(55) Input foreclosure arises where, post-transaction, the new entity would be likely to restrict access to the products or services that it would have otherwise supplied absent the vertical merger, thereby raising its downstream rivals’ costs by making it harder for them to obtain supplies of the input under similar prices and conditions as absent the vertical merger.71

(56) Customer foreclosure may occur when a supplier integrates with an important customer in the downstream market. Because of this integration, the merged entity may foreclose access to a sufficient customer base to its actual or potential rivals in the upstream market and reduce their ability or incentive to compete. In turn, this may raise downstream rivals’ costs by making it harder for them to obtain supplies of the input under similar prices and conditions as absent the vertical merger.72

(57) For an input or customer foreclosure scenario to raise competition concerns, three cumulative factors need to be taken into account: (i) the ability of the merged entity to engage in foreclosure; (ii) the incentives of the merged entity to do so; and (iii) whether a foreclosure strategy would have a significant detrimental effect on competition in the downstream market.73

6.3. Input foreclosure

6.3.1. The Notifying Party’s views

(58) The Notifying Party submits that the Parties do not have the ability to foreclose rival SAL suppliers from access to release liners since, although Ahlstrom-Munksjö has a […]% market share in the plausible market for the supply of glassine release liners, it only holds […]% of the EEA capacity. Moreover, it faces significant constraints from important EEA rivals, release liner capacity is increasing in the EEA and clients have strong bargaining power.74

(59) The Notifying Party claims that the Parties would have no incentive to foreclose each other’s rivals namely because Fedrigoni is too small to be able to realistically capture a sufficient number of end-customers in the downstream market to compensate for foregoing profits made upstream by the lost sale of release liner.

(60) Finally, the Notifying Party claims that this vertical relationship will result in no adverse effect on competition, as any hypothetical input foreclosure strategy would fail. According to the Notifying Party, if Ahlstrom-Munksjö ceased supplying release liners to Fedrigoni’s rivals, increased its prices or reduced its service levels, customers of release liners would be able to switch their demand to a number of other release liner suppliers and Ahlstrom-Munksjö would immediately lose a significant portion of its turnover.

6.3.2. The Commission’s assessment

(61) Ahlstrom-Munksjö has high or relatively high combined market shares in the upstream markets for the manufacture and supply of release liners. In particular, in the plausible market for the manufacture and supply of glassine release liners its market shares are […]% by sales (including captive sales), [50-60]% (excluding captive sales) and […]% by capacity.75 However, the Commission considers that the merged entity will not likely have the ability and the incentive to foreclose downstream competitors in the manufacture and supply of SAL, and that any foreclosure strategy would not have a significant detrimental effect on competition downstream, for the following reasons.76

(62) As regards ability to foreclose, first, as the Notifying Party has explained, there are numerous alternative suppliers who offer paper-based release liners, including also glassine release liners. These include UPM, Dunafin (Delfort), Torraspapel (Lecta), Sappi, Ermolli, ITASA, Loparex, etc.

(63) Second, during the market investigation, release liners suppliers confirmed that there is significant spare capacity in the market. All the release liners suppliers who replied to the market investigation indicated that they would be able to increase production of release liners, including for paper-based release liners, if they received more customer orders in Europe.77 In particular, UPM confirmed that in 2020 it has expanded its capacity for the production of glassine release liners by 120 kt in its mill in Germany. Moreover, according to the respondents to the market investigation, other suppliers such as Cartiere Ermolli (Italy) and Rosella (Italy) would have expanded its release liners capacity in the last five years.78 As regards future capacity expansions, Delfort (Austria) confirmed that it plans to expand capacity within the next five years.79 According to some respondents, and in line with the Notifying Party’s argument, Lecta (France) is also expected to bring additional release liner capacity in the short-term.80 In this regard, the Commission considers that Ahlstrom-Munksjö’s high market shares in 2019 do not fully reflect the current competitive dynamics given the additional capacity brought to the market in 2020 (and in the next years) and in view of the fact that […].81

(64) In reply to the market investigation, the only barrier to entry that was consistently mentioned by release liners suppliers is the cost of building a new mill.82 In this regard, release liners suppliers have identified new entrants in China and Taiwan in 2019 and 2020.83 These new entrants may supply customers located in the EEA since, as explained in section (5.2), the vast majority of customers purchase release liners at worldwide level.

(65) Third, although there is a qualification process required to switch release liners suppliers,84 all the SAL suppliers who responded to the market investigation indicated that they already multisource from various release liners suppliers.85

(66) Moreover, the Commission considers that the Parties would not have the incentive to engage in an input foreclosure strategy since release liners do not appear to be an important cost element of SAL.86 Moreover, Fedrigoni’s downstream market share for SAL, as well as its purchasing market share in the market for the manufacture and supply of glassine release liners in the EEA are moderate.87 Therefore, any attempt at foreclosure would result in a loss of the majority of its upstream business for the merged entity were it to pursue this strategy, and would not offer its downstream operation any material benefit.88

(67) In conclusion, and in view of the above, the Parties do not appear to have the ability or the incentive to engage in input foreclosure strategies and any foreclosure strategy would not have a significant detrimental effect on competition downstream.

6.4. Customer foreclosure

6.4.1. The Notifying Party’s view

(68) The Notifying Party submits that the Parties do not have the ability to foreclose Ahlstrom-Munksjö’s competitors given that Fedrigoni is not an important customer for release liners. According to the Notifying party, Fedrigoni’s EEA share for the supply of SAL overall is […]% and it purchases only a small share of the release liners sold in the EEA overall ([…]%), and an estimated […] Kt of glassine/SCK release liners in 2019 in the EEA, which corresponds to […]% of the total supply of glassine/SCK release liners in the merchant market ([…]). According to the Notifying Party, even if Fedrigoni purchased all of its release liner demand from Ahlstrom-Munksjö, a large customer base would still remain in the EEA for upstream competitors (including Avery Dennison, UPM Raflatac, Herma and 3M).89

6.4.2. The Commission’s assessment

(69) The Commission considers that the Parties will likely not have the ability to engage in customer foreclosure strategies and that any foreclosure strategy would in any event not have a significant detrimental effect on customers in the downstream market, for the reasons explained below.

(70) As regards ability to foreclose and as explained in paragraph (57), customer foreclosure may occur when a supplier integrates with an important customer in the downstream market. However, Fedrigoni is not an important customer in the overall release liners market or in the glassine release liners market, neither in the EEA or worldwide.90

(71) First, Fedrigoni’s market share in all plausible markets related to the manufacture and sale of SAL is clearly below 30%, as shown in Table 5:. In the EEA market for the supply of SAL, Fedrigoni has a market share between [10-20]% and [20-30]% for all plausible segments in the EEA, and purchases only a small share of the release liners sold ([…]%).91 Therefore, even if Fedrigoni decided to obtain all its needs for release liners from Ahlstrom-Munksjö, competitors in the release liners market would still have other customers available in the EEA, such as Avery Dennison, UPM Raflatac, Herma or 3M. Avery Dennison and UPM Raflatac are the largest suppliers of SAL in the EEA with market shares of [30-40]% and [30-40]% respectively in the supply of SAL overall (see Table 6).

(72) Second, Fedrigoni purchased […] of glassine release liners92 in 2019 in the EEA,93 corresponding to […]% of the total supply of glassine release liners to third parties (i.e. […], as shown in Table 3). Therefore, if post-Transaction Fedrigoni decided to purchase all of its glassine release liners from Ahlstrom-Munksjö, there would still remain a large customer base for third parties corresponding to […]% of the sales of glassine release liners made in the EEA in 2019.

(73) Third, in 2019, Fedrigoni purchased […] of glassine release liners from Ahlstrom- Munksjö, representing […]% of its total purchases.94 Therefore, Fedrigoni’s purchases of release liners from third parties other than Ahlstrom-Munksjö represented […] Kt, that is […]% of the total sales made in the EEA in 2019.

(74) Since the merged entity will thus not likely have the ability to engage in customer foreclosure, it is not necessary to analyse its incentives, as those conditions are cumulative.

(75) As regards the impact of any foreclosure strategy, all of the respondents to the Questionnaire for suppliers of release liners stated that they would have sufficient alternative customers for release liners if Fedrigoni were to source all its needs for release liners from Alhstrom-Munksjö.95 One supplier of release liners explained that “[name of supplier] is not depending on a unique customer [.] Ritrama/Fedrigoni is an important customer for [name of supplier] but in an organic growing market, [name of supplier] is not depending on an unique customer”.96 None of the suppliers of release liners considered that the Transaction would have a negative impact on their companies97 or in the market for release liners.98 One supplier of release liners explained that “[t]he deal creates a new forward integrated group of companies in the pressure sensitive materials business, but that is not new to the industry. There are globally other examples of similar instances.”99

(76) One SAL material supplier expressed concerns that “[a]fter the consolidation between Arconvert(Fedrigoni) and Ritrama, the Arconvert-Ritrama Group has become one of the biggest Label Manufacturers around the world. (No.1 – Avery Dennison, No.2 – UPM Raflatac, No.3 – Arconvert-Ritrama). Based on our internal estimation, the aforesaid top 3 companies will occupy more than 70% of the global market share. UPM Group has internal integration and raw material supply between UPM Specialty Paper & UPM Raflatac. If Fedrigoni at the post-transaction stage were to source all its needs from Ahlstrom-Munksjo, it might create an unjustified competition environment for the release liner market, especially for glassine products” and that “[f]or the SAL users (ex: FMCG brand owner, Wine Brewer...), this integration will create an oligopoly environment in SAL markets around the top 3 suppliers. The medium and small SAL suppliers will face a fierce competition from the behemoths. It might decrease the freedom and choice for the end-users in Europe Region”.100 However, given that Fedrigoni’s purchases of third-party glassine release are limited (see paragraphs (73) and (74)) and the fact that the Transaction does not result in an increment of Fedrigoni’s share of SAL, it can be concluded that the Transaction does not raise foreclosure concerns.101

(77) In conclusion and in view of the above, the Parties do not appear to have the ability to engage in customer foreclosure strategies and any foreclosure strategy would not have a significant detrimental effect on customers in the downstream market.

7. CONCLUSION

(78) For the above reasons, the European Commission has decided not to oppose the notified operation and to declare it compatible with the internal market and with the EEA Agreement. This decision is adopted in application of Article 6(1)(b) of the Merger Regulation and Article 57 of the EEA Agreement.

1 OJ L 24, 29.1.2004, p. 1 (the “Merger Regulation”). With effect from 1 December 2009, the Treaty on the Functioning of the European Union (“TFEU”) has introduced certain changes, such as the replacement of “Community” by “Union” and “common market” by “internal market”. The terminology of the TFEU will be used throughout this decision. For the purposes of this Decision, although the United Kingdom withdrew from the European Union as of 1 February 2020, according to Article 92 of the Agreement on the withdrawal of the United Kingdom of Great Britain and Northern Ireland from the European Union and the European Atomic Energy Community (OJ L 29, 31.1.2020, p. 7), the Commission continues to be competent to apply Union law as regards the United Kingdom for administrative procedures which were initiated before the end of the transition period.

2 OJ L 1, 3.1.1994, p. 3 (the “EEA Agreement”).

3 Publication in the Official Journal of the European Union No C 417, 2.12.2020, p. 58.

4 Turnover calculated in accordance with Article 5 of the Merger Regulation.

5 A possible wider market for release liners for other uses was also considered, even though SAL account for about three quarters of the total demand for release liners. However, the Parties only use release liners for the production of SAL and therefore this decision focuses only on the smallest plausible market which is the market for SAL.

6 The Notifying Party confirms that there are no horizontal overlaps between Ahlstrom-Munksjö and any other controlled Bain Capital portfolio company, and that other actual or potential vertical links between the Parties do not give rise to affected markets (Form CO, paragraphs 28-32).

7 Calendering is the process of smoothing the surface of the paper by pressing it between hard pressure cylinders or rollers (the calenders) at the end of the papermaking process. It is the last step of the process before the paper is cut to standard sizes. Kraft paper is the most commonly used material in packaging and made from at least 80% sulfate wood pulp. It is also used in the manufacturing of various types of release liners.

8 Paper-based release liners can be used for both paper-based and film-based SAL (in sheets and in rolls). Similarly, film-based release liners can be used for both paper-based and film-based SAL (in sheets and in rolls). See reply to RFI 5.

9 Whereas glassine is the primary release liner type used in Europe, in North America the primary release liner types used is SCK, which is a slightly different product (in terms of process and composition) but is used for the same applications (i.e. SAL, tape, industrial and medical applications). Glassine release liners is the term used in this Decision.

10 For the purposes of this Decision, the EEA is understood to cover the 27 Member States of the European Union (Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia, Slovenia, Spain and Sweden) and the United Kingdom, as well as Iceland, Liechtenstein and Norway. Accordingly, any references made to the EEA in this Decision are meant to also include the United Kingdom (UK).

11 M.5155, Mondi/Loparex Assets, paras. 10-26, M.6668, Mondi/Nordenia, paras. 16-18.

12 Reply to question 7.1 of the Questionnaire for release liners suppliers.

13 Reply to question 6.1 of the Questionnaire for release liners suppliers.

14 Reply to question 8.1 of the Questionnaire for release liners suppliers.

15 Reply to question 9.1 of the Questionnaire for release liners suppliers.

16 Reply to question 20.1 of the Questionnaire for SAL suppliers.

17 Reply to question 18.1 of the Questionnaire for SAL suppliers.

18 Reply to question 5.1.1 of the Questionnaire for release liners suppliers.

19 Reply to question 7.1 of the Questionnaire for release liners suppliers.

20 Reply to question 9.1 of the Questionnaire for release liners suppliers.

21 Reply to question 11.1 of the Questionnaire for release liners suppliers.

22 “Majority” in this Decision stands for more than 50% of the participants in the market investigation who replied to the question, excluding those that replied “other”, or “I do not know”.

23 Reply to question 17 of the Questionnaire for SAL suppliers.

24 Reply to question 18 of the Questionnaire for SAL suppliers.

25 Reply to question 17.1 of the Questionnaire for SAL suppliers.

26 The plausible market for the manufacture and supply of CCK release liners will not be further discussed as it is not affected under any plausible geographic market definition.

27 One respondent to the Commission’s market investigation explained that “[t]he decision on paper, film, rolls, sheets depends on myriad factors including, without limitation, the end use application and the preferences and needs of the end-user and converter. The environment and purpose of the end-use application often dictates whether paper or filmic SAL is used, but end-user preference and cost are also very important. […] All automated label applicators require roll materials (vast majority of end use applications). Sheets are typically used for hand applied applications and smaller quantities (e.g. stickers) Squeezable containers often require a squeezable (i.e. filmic/PE) label For cost and recycling reasons, you would not put a filmic shipment label on a carton box.” Reply to question 7.1 of the questionnaire for SAL suppliers.

28 M.2867 UPM/Kymmene Corporation/Morgan Adhesives Companies, paras. 15-19.

29 M.2867 UPM/Kymmene Corporation/Morgan Adhesives Companies, para 13.

30 Form CO, paragraphs 126-128.

31 Reply to question 5 of the Questionnaire for SAL suppliers and to question 4 of the Questionnaire for SAL customers.

32 Replies to question 4.1 of the Questionnaire for SAL customers.

33 Replies to question 5.1 of the Questionnaire for SAL suppliers.

34 Reply to question 8.1 of the Questionnaire for SAL suppliers.

35 Reply to questions 8.1 and 9.1. of the Questionnaire for SAL suppliers.

36 “All” in this Decision stands for 100% of the participants in the market investigation who replied to the question, excluding those that replied “other”, or “I do not know”.

37 Reply to question 10.1 of the Questionnaire for SAL suppliers and question 8.1. of the Questionnaire for SAL customers.

38 Reply to question 6 of the Questionnaire for SAL suppliers and to question 5 of the Questionnaire for SAL customers.

39 Reply to question 6 of the Questionnaire for SAL suppliers.

40 Reply to question 5 of the Questionnaire for SAL customers.

41 Reply to questions 8.2 and 9.2. of the Questionnaire for SAL suppliers.

42 Reply to question 10.2 of the Questionnaire for SAL suppliers and question 8.2 of the Questionnaire for SAL customers.

43 M.5155, Mondi/Loparex Assets, para. 29.

44 Reply to question 12 of the Questionnaire for release liners suppliers.

45 Reply to question 14 of the Questionnaire for release liners suppliers.

46 Reply to RFI 2 and RFI 3.

47 Reply to question 13 of the Questionnaire for release liners suppliers.

48 Reply to question 27 of the Questionnaire to SAL suppliers.

49 Reply to question 28 of the Questionnaire to SAL suppliers.

50 Reply to question 33 of the Questionnaire to SAL suppliers.

51 M.2867, UPM/Kymmene Corporation/Morgan Adhesives Companies, paras. 15-17.

52 Form CO, paragraphs 130-137.

53 Reply to question 11 of the Questionnaire for SAL suppliers and to question 10 of the Questionnaire for SAL customers.

54 Reply to question 10.1 of the Questionnaire for SAL customers.

55 Reply to question 11.1 of the Questionnaire for SAL suppliers.

56 Reply to question 12 of the Questionnaire for SAL suppliers and to question 13 of the Questionnaire for SAL customers.

57 Reply to question 13.1 of the Questionnaire for SAL suppliers.

58 Reply to question 11.1 of the Questionnaire for SAL suppliers.

59 Reply to question 10.1 of the Questionnaire for SAL customers.

60 Fedrigoni produces a negligible volume of glassine release liners in the EEA (approximately […] in 2019), exclusively for internal consumption by the company’s Pressure Sensitive Labels business unit. Fedrigoni has never supplied the merchant market, […]. Accordingly, no horizontal overlap arises in the supply of release liners to the merchant market in the EEA.

61 The Notifying Party submitted that 2017 and 2018 market shares at EEA level do not differ significantly from 2019 market shares. According to the Parties’ estimates, the combined market shares of the Parties remain […] below 30% at worldwide level.

62 In the EEA, Ahlstrom-Munksjö is only active in the production and supply of glassine and CCK release liners, both of which are paper-based. Therefore, the release liner market sizes and shares presented in this Decision conservatively include all paper-based release liners but not film-based release liners. Capacity market sizes and shares include only glassine and CCK release liners.

*Should read [0-5].

63 The Notifying Party submitted that 2017 and 2018 market shares at EEA level do not differ significantly from 2019 market shares. According to the Parties’ estimates, the combined market shares of the Parties remain below 30% at worldwide level.

64 [Methodology used to calculate capacity market shares].

65 Ibid.

66 Ibid.

67 The Notifying Party submitted that 2017 and 2018 market shares do not differ significantly from 2019 market shares.

68 The Notifying Party submitted that 2017 and 2018 market shares do not differ significantly from 2019 market shares

69 Guidelines on the assessment of non horizontal mergers under the Council Regulation on the control of concentrations between undertakings (OJ C 265, 18.10.2008, p. 6) (“Non-horizontal Merger Guidelines”).

70 Non-Horizontal Merger Guidelines, paragraph 29.

71 Non-Horizontal Merger Guidelines, paragraph 31.

72 Non-Horizontal Merger Guidelines, paragraph 58.

73 Non-Horizontal Merger Guidelines, paragraphs 32 and 59.

74 Form CO, paragraph

75 The combined market shares in the overall market for the manufacture and supply of release liners in the EEA are below 30%. In particular, the Parties achieve […]% of the sales including captive sales, [20- 30]% excluding captive sales and […]% in terms of capacity.

76 The Commission notes that two SAL suppliers indicated in the market investigation that the Transaction may have a negative impact on competition. However, the Commission considers that these concerns are unfounded for the reasons set out in this section.

77 Out of which only one indicated that it would not be able to increase production of glassine release liners in the short term. See reply to questions 17 and 20 of the Questionnaire for release liners suppliers.

78 Reply to question 23 of the Questionnaire for suppliers of release liners.

79 Reply to question 24 of the Questionnaire for suppliers of release liners.

80 Reply to questions 25 and 27.3 of the Questionnaire for suppliers of release liners.

81 Form CO, paragraph 310.

82 Reply to question 28.1 of the Questionnaire for suppliers of release liners.

83 Reply to question 26.3 of the Questionnaire for suppliers of release liners.

84 Reply to question 35 of the Questionnaire for SAL suppliers.

85 Reply to question 38 of the Questionnaire for SAL suppliers.

86 The cost of release liners constitutes only a small proportion of the price of SAL, less than 20%.

87 Fedrigoni’s share in the downstream market for the supply of SAL in the EEA is only [10-20]%.

88 In 2019 Ahlstrom-Munksjö sold […] of glassine release liners, out of which […] were sold to Fedrigoni and […] to third parties. If post-Transaction Fedrigoni decided to purchase all its needs of glassine release liners (i.e., […]) from Ahlstrom-Munksjö, they would only represent […]% of the total sales made by Ahlstrom-Munksjö. Therefore, […]% of Ahlstrom-Munksjö’s production of glassine release liners would be available for competing SAL suppliers.

89 Form CO, paragraphs 33 and 34.

90 Given that in any plausible SAL product market Fedrigoni’s market share worldwide is below its market share in the corresponding market in the EEA, the Commission will carry out the competitive assessment on the basis of the narrowest possible geographic market, that is, an EEA-wide market.

91 Form CO, paragraph 33.

92 The only type of release liner where Ahlstrom-Munksjö’s market share is above 30% is glassine release liners.

93 Form CO, paragraph 33 and footnote 15.

94 Reply to question 6 of RFI 2.

95 Reply to question 30 of the Questionnaire for suppliers of release liners.

96 Reply to question 30.1 of the Questionnaire for suppliers of release liners.

97 Reply to question 31 of the Questionnaire for suppliers of release liners.

98 Reply to question 32 of the Questionnaire for suppliers of release liners.

99 Reply to question 31.1 of the Questionnaire for suppliers of release liners.

100 E-mail from a SAL material supplier of 29 December 2020.

101 Another release liners supplier raised concerns that “[t]here are non-integrated players, esp. in southern Europe, which may face disadvantages as a result of not being vertically integrated” (reply to question 33.1 of the Questionnaire for release liners suppliers). However, given the existence of spare capacity in the release liners market and the fact that Fedrigoni is a relatively small player in the SAL market, the Transaction is unlikely to result in competition concerns for non-integrated players, who will be able to continue to (i) supply release liners to other SAL producers and (ii) purchase release liners from different release liners manufacturers, as applicable.