Commission, October 4, 2016, No M.7801

EUROPEAN COMMISSION

Decision

WABTEC / FAIVELEY TRANSPORT

COMMISSION DECISION

of 4.10.2016

declaring a concentration to be compatible with the internal market and the EEA Agreement (Case M.7801 – WABTEC / FAIVELEY TRANSPORT)

(Only the English text is authentic)

THE EUROPEAN COMMISSION,

Having regard to the Treaty on the Functioning of the European Union,

Having regard to the Agreement on the European Economic Area, and in particular Article 57 thereof,

Having regard to Council Regulation (EC) No 139/2004 of 20 January.2004 on the control of concentrations between undertakings1, and in particular Article 8(2) thereof,

Having regard to the Commission's Decision of 12 May 2016 to initiate proceedings in this case,

Having regard to the opinion of the Advisory Committee on Concentrations2,

Having regard to the final report of the Hearing Officer in this case 3,

Whereas:

1. THE NOTIFICATION

(1) On 4 April 2016, the Commission received a notification of a proposed concentration pursuant to Article 4 of Council Regulation (EC) No 139/20044 (the ‘Merger Regulation’), by which the undertaking Westinghouse Air Brake Technologies Corporation (‘Wabtec’) would acquire within the meaning of Article 3(1)(b) of the Merger Regulation indirect sole control of the whole of the undertaking Faiveley Transport S.A. (‘Faiveley’) by way of purchase of shares (the ‘Transaction’). Wabtec is hereinafter referred to as the ‘Notifying Party’ whereas Wabtec and Faiveley are collectively referred to as the ‘Parties’.

2. THE PARTIES

(2) Wabtec is a US-based international undertaking active in the manufacture and supply of railway equipment and in the provision of services in the railway sector. It is the market leader on the American continent.

(3) Faiveley is a French-based undertaking active in the manufacture and supply of integrated systems and services for the railway sector. Its activities focus on the European market.

3. THE OPERATION AND THE CONCENTRATION

(4) The operation consists of two steps. First, Wabtec will indirectly acquire 51.5% of shares in Faiveley pursuant to a share purchase agreement signed on 6 October 2015. As a result Wabtec will achieve sole control of Faiveley. Second, Wabtec will launch a mandatory tender offer for the remaining shares in Faiveley.

(5) The operation therefore constitutes a concentration within the meaning of Article 3(1)(b) of the Merger Regulation.

4. UNION DIMENSION

(6) The undertakings concerned have a combined aggregate world-wide turnover of more than EUR 2 500 million5 (Wabtec EUR 2 292 million; Faiveley EUR 1 048 million). The combined aggregate turnover of the undertakings concerned in each of Germany, France, Italy and the United Kingdom is more than EUR 100 million and the aggregate turnover of each undertaking concerned is more than EUR 25 million in each of those four Member States. Each of the undertakings concerned has a Union-wide turnover in excess of EUR 100 million (Wabtec EUR [...] million; Faiveley EUR [...] million) but they do not achieve more than two-thirds of their aggregate Union-wide turnovers within one and the same Member State.

(7) The concentration therefore has a Union dimension pursuant to Article 1(3) of the Merger Regulation.

5. THE PROCEDURE

(8) On 4 April 2016, the Commission received the notification in the case.

(9) On 12 May 2016, the Commission adopted a decision pursuant to Article 6(1)(c) of the Merger Regulation, opening proceedings (the ‘Article (6)(1)(c) Decision’).

(10) On 17 June 2016, the Commission adopted a decision pursuant to Article 10(3) of the Merger Regulation, extending the deadline for adopting a final decision by 20 days with agreement of the Notifying Party.

(11) On 8 July 2016, the time limit for adopting a final decision was suspended in accordance with Article 10(4) of the Merger Regulation and Article 9 of Commission Regulation (EC) No 802/2004 implementing the Merger Regulation. The suspension ended on 13 July 2016.

(12) On 25 July 2016, the Notifying Party submitted commitments to the Commission (‘First Commitments’).

(13) On 25 July 2016, the Commission launched a market test to assess whether the First Commitments were suitable to address the competition concerns identified by the Commission.

(14) On 16 August 2016, the Notifying Party submitted revised commitments to the Commission (‘Final Commitments’).

(15) The meeting of the Advisory Committee took place on 22 September 2016.

6. COMPETITIVE ASSESSMENT

6.1. General

(16) The Parties are global suppliers of various types of train equipment to rolling stock manufacturers and train operators. Together with Knorr-Bremse, they are the three major worldwide suppliers of such equipment. As a result of the Transaction, the merged entity would become ‘a new global railway equipment leader’, ahead of Knorr-Bremse.6

(17) Globally, Faiveley appears to concentrate more on the European markets and on passenger transport while Wabtec is stronger in the US and in freight applications. That may be due to historic reasons and due to the fact that the rail market in Europe is to a large extent a passenger market while in the US it is a freight market, save for some urban transit such as underground vehicles. However, both Parties manufacture and supply a broad range of equipment for both freight and passenger transit applications.

(18) Within the EEA, their activities overlap with respect to the supply of (i) complete friction brake systems and their subsystems; (ii) friction materials; (iii) brake discs; (iv) pantographs; (v) train doors; (vi) energy meters; and (vii) event recorders. Affected markets7 arise with respect to all of those products except train doors, energy meters and event recorders.8

(19) The Transaction would also give rise to vertically affected markets between the Parties’ activities in friction materials (upstream) and activities in complete brake systems (downstream).

6.2. Original equipment market (‘OEM’) and independent aftermarket (‘IAM’); homologation

(20) In the train industry, trade generally takes place on two levels: (i) sales to original equipment manufacturers (‘OEMs’), including both rolling stock manufacturers and subsystem manufactures, and (ii) sales in the independent aftermarket (‘IAM’). The Commission nonetheless considered in its recent decision in M.7538 – Knorr Bremse / Vossloh that since the IAM market largely mirrors the OEM market, it was adequate to assess the OEM market only.9 The case concerned train systems such as brake systems – but not components that require regular replacement such as friction materials or brake discs.

(21) The Notifying Party submits that it is appropriate to assess only the OEM markets with the exception of (i) brake discs and (ii) friction materials for which meaningful IAM markets exist, with suppliers selling directly to the train operators.

(22) The market investigation has not called the findings in M.7538 – Knorr Bremse / Vossloh into question. The Commission will therefore assess the markets for train systems and subsystems at the OEM level. However, for components that need regular replacement, the situation may be different.

(23) The Notifying Party also notes that many train equipment such as brake systems and pantographs (and even for instance friction materials) usually need to undergo a homologation procedure to demonstrate compliance with the regulatory requirements. The complexity and the duration of the homologation process varies depending on the importance of the product to the safety of the train. In general the homologation requirement supports the procurement of spare parts from the supplier of the original parts of the train as a new homologation may be needed if replacing original components of a train system with spare parts from another supplier.

6.3. Energy meters

6.3.1. Relevant product markets

(24) The Parties' activities overlap horizontally with regards to energy meters.

(25) Energy meters are installed in railway vehicles to facilitate the exact measurement of energy consumption. This serves two main purposes: (1) providing consumption data for the identification and assessment of potential energy saving measures; and (2) providing consumption data to permit more precise billing for the electricity used.10

(26) Energy meters are used in various rail-operated vehicles, but are used in particular in high-speed trains and electrically-powered regional trains.

(27) Energy meters generally consist of a sensor and a Data Handling System ('DHS'). The energy sensor calculates the active and reactive energy consumption of a train during traction, as well as regeneration during braking. The sensor sends the energy data to the DHS for processing, storage and/or transmission to a ground server. The DHS typically produces profiles of energy usage over set periods of time.

(28) These parts (sensor and DHS) are usually sold together. The main exception involves Wabtec’s sales to [...].11

(29) The European standard EN 50463 sets requirements for energy measurement with rolling stock. Thus, all manufacturers’ energy meters in the EEA are designed to satisfy the requirements of EN 50463. Energy meters are sold both to OEMs for incorporation into new trains and to rail operators for retrofit of existing train fleets. Thus, energy meters are supplied both to OEM and IAM customers.

(30) There are no precedents from the Commission or a national competition authority that define the relevant market for energy meters for trains.

(31) The Notifying Party submits that the relevant product market encompasses all energy meters.

(32) From a demand-side point of view, customers follow the European standard EN 50463 which sets requirements for the supply of energy meters with respect to the level of accuracy and the time reference period. Demand is therefore not differentiated.

(33) From a supply-side point of view, most suppliers offer a similar range of energy meters. This is notably because European standard EN 50463, which sets functional requirements for energy meters, has resulted in similarity among suppliers of basic energy meters.

(34) As explained in recital 28, a product market definition at component level (sensors and DHS) would probably not make sense since energy meters are mostly sold together.

(35) Therefore, on this basis, it appears that the most plausible product market definition encompasses all energy meters. The relevant product market definition for energy meters can however be left open in this case since no competition concerns would arise under the narrowest segmentation possible.

6.3.2. Relevant geographic markets

(36) There are no precedents from the Commission or a national competition authority that define the relevant market for energy meters for trains.

(37) In the absence of a Commission precedent, the Notifying Party submits that the relevant geographic market for energy meters is EEA-wide because there are no legal barriers to trade, major competitors are competing across the EEA, and all are TSI approved. The response to recent and ongoing bids in France, Germany, Switzerland and the Nordic countries provides concrete evidence of cross-border competition. As an example, the Italian company Saira won a retrofit project in 2015 for the supply of stand-alone energy meters in Norway, Sweden and Denmark.

(38) Nothing in the market investigation suggests that the Notifying Party's proposed product and geographic definitions are incorrect. Moreover, the relevant geographic market definition for energy meters can be left open in this case since no competition concerns would arise under the narrowest segmentation possible.

6.3.3. The Parties' activities and lack of affected market

(39) Wabtec sells energy meters in the EU through its wholly-owned subsidiary, Mors Smitt, based in France. It has manufacturing locations in several EEA countries, as well as in China.

(40) Faiveley also sells energy meters in the EEA but manufactures only in France. Faiveley began development of its energy meter in 2008, before the adoption of the standard EN 50463 in 2012. Faiveley thus had to select an architecture for its product without the benefit of knowing what the industry-wide standard would be, and therefore offers a slightly differentiated product – known as DEMETRA. Since the adoption of EN 50463, [...].

(41) In 2014, Faiveley won a large contract from the French government-owned SNCF to retrofit 700 TGV trains, [...].

(42) Therefore, the Parties' activities overlap horizontally in the market for energy meters in the EEA. The overlap exists at both OEM and IAM level, at least potentially.

(43) As regards components, [...]. Therefore, the Parties’ activities do not overlap in relation to the supply of DHSs or sensors on a stand-alone basis. [...]

(44) The Transaction would not give rise to any affected markets, even if the narrowest possible sub-segments are considered in isolation. The Commission notes that the Parties' combined share in the potential sub-segment for retrofit energy meters in the EEA, for the period 2011–2014 amounts to [10-20]%. [...] . This [...] gives Faiveley a [10-20]% market share, while the negligible increment of [0-5]% is attributable to Wabtec's market share.

(45) Competitors include LEM, Microelletrica, Saira, Bombardier, and Alstom. The Commission notes that the Parties’ combined market share remains modest and that a number of notable competitors would remain on the market after the Transaction.

(46) In the market investigation, a majority of rolling stock manufacturers did not think that the Transaction would affect competition with respect to energy meters and event recorders. Rail operators were less enthusiastic about the transaction with a quarter of them believing the transaction would negatively affect competition for energy meters and event recorders, a majority not knowing, and roughly a fifth thinking the Transaction would not affect competition.12

(47) On the basis of the absence of affected market, the Commission considers that the Transaction is unlikely to give rise to a significant impediment to effective competition in the EEA with respect to energy meters.

6.4. Event recorders

6.4.1. Relevant product markets

(48) The Parties' activities overlap horizontally with respect to event recorders.

(49) Event recorders are used to record data relating to the operation of train controls and performance. Most rolling stock contain an event recorder for safety reasons in case of an accident, as the data recorded (e.g., data relating to the operation of train, including the train’s location and speed, application of the brakes, operation of the doors, etc.) is important evidence to determine the possible causes of an accident.

(50) Neither the Commission nor the national competition authorities have defined markets for railway event recorders. The only potentially relevant decision is General Electric/Honeywell, where the Commission dealt with flight data recorders. In that decision, the Commission considered the products to be part of a wider market of buyer-furnished equipment for avionics products.13

(51) In the absence of a relevant Commission precedent, the Notifying Party submits that the relevant product market consists of a single market for sales of railway event recorders. This includes sales of event recorders to OEMs and end users and for all types of rolling stock.

(52) From the point of view of demand-side substitutability, customer demand is determined by the specifications of each customer for each vehicle according to the level of complexity of each system. The design of event recorders does not depend on (i) the type of customer, (namely an OEM compared to an end-user), or (ii) the type of rolling stock (transit compared to freight). OEMs and end-users typically set specific requirements for event recorders for each particular train. Thus, one OEM/end-user may require a complex event recorder for a high-speed train, whereas another OEM/end-user may request a more basic event recorder for a high-speed train. Therefore, the end-user requirements vary depending on the complexity of the system desired by the customer. Regulatory requirements are generally consistent across most types of rolling stock.

(53) From a supply-side point of view, all suppliers offer modular multifunctional event recorders. These event recorders can be tailored for any type of rolling stock and for both newly built and retrofit applications. The core design of an event recorder is similar for all suppliers. As a result, all event recorders are generally substitutable.

(54) Therefore the most plausible product market definition seems to encompass all event recorders. The relevant product market definition for events recorders can however be left open in this case since no competition concerns would arise under the narrowest segmentation possible.

6.4.2. Relevant geographic markets

(55) In the absence of a relevant Commission precedent, the Notifying Party submits that the relevant geographic market for event recorders is at least EEA-wide, notably because tender procedures confirm the existence of extensive cross-border trade and little differentiation in pricing.

(56) The Notifying Party nevertheless recognizes that national regulations play an important role in the market for event recorders. As a consequence, the design of an event recorder may vary depending on the country in which the train will be installed and operated. In particular, the UK requires standards that differ from the rest of Europe.

(57) In the UK, the standards GM/RT2100, 2130, 2304 and 2472 result in designs of event recorders that are closer to US-designed event recorders in terms of the degree of enclosure hardening that is required. These event recorders consist of a resilient closed box. The closed structure of the device makes it less modular since input/output interfaces are more difficult to add.

(58) For the rest of Europe, the European standards result in the design of event recorders with a more open structure, which make them more flexible and modular. This makes it somewhat easier to customize event recorders designed to European rather than UK standards.

(59) In addition, trains running on the French national railway network must be equipped with a specific device called ATESS14, which includes an event recorder function. ATESS is supplied solely by Faiveley. Since no other EEA country has adopted similar regulations, and since ATESS are not substitutable with normal event recorders, they seem to form a market of their own where Faiveley is the only competitor.

(60) The Commission notes that the different regulatory standards that exist in different EEA countries impact demand and supply-side substitutability. Wabtec will be naturally more successful in the UK where its US-standards compliant event recorders will be more fitting, whereas a supplier like Faiveley will be naturally more successful in continental countries such as France where its event recorders' architecture fits the regulatory standards.

(61) The relevant geographic market definition for events recorders can however be left open in this case since no competition concerns would arise even under the narrowest plausible geographic market definition, whether the market is defined at national level (in which case there would be no overlap) or EEA-wide.

6.4.3. Parties' activities

(62) Wabtec sells event recorders in the EEA. Wabtec’s event recorders are based on products designed for the North American market. Its sales in the EEA are limited to the UK and made on an occasional basis.

(63) Faiveley mainly sells event recorders designed to comply with regulations applicable to event recorders in the rest of Europe. Those requirements led to a specific design of event recorder, which incorporates a box that is not as tightly sealed as Wabtec’s. This type of event recorder is more flexible and modular, and better adapted to supporting the additional functionalities sought by many European customers. Faiveley sells event recorders in France, Belgium, Germany and Italy.

(64) As a result, the Parties’ sales do not overlap at a national level.

(65) At EEA level, the Parties' sales of event recorders do overlap but do not amount to an affected market, with Faiveley having a market share of [5-10]% over the period 2011-2014, and the increment consisting in Wabtec's negligible market share of [05]%.

(66) As explained above at recital 59, ATESS probably constitute a product market of their own, but for the sake of completeness, the Commission notes that Faiveley's market share rises to [20-30]% if ATESS sales are included in the overall events recorder market. As noted Wabtec does not produce ATESS, and, if they are included in the overall events recorder market, its market share drops to [0-5]%.

(67) In addition, multiple suppliers ensure competition for railway event recorders in the EEA. Deuta-Werke and Hasler are the two leading suppliers of event recorders in the EEA. They have broad product ranges and well-established relationships with OEMs and end users, and they compete for most opportunities throughout the EEA. Post-Transaction, the combined entity would continue to face strong competitors on the market for event recorders. Hasler and Deuta-Werke in particular would exert significant competitive pressure on the post-merger entity.

(68) There is no affected market in case the most plausible market definition (event recorders without ATESS) is retained. In case the less plausible market definition of event recorders including ATESS is retained, the Transaction would give rise to an affected market. However, the increment in the Parties' combined market share would be so minimal ([0-5]%) that it could not reasonably give rise to any merger-specific effects. Therefore, the Commission considers that the Transaction is unlikely to give rise to significant impediment to effective competition in the EEA with respect to event recorders.

6.5. Doors

6.5.1. Relevant product markets

6.5.1.1. Background and previous cases

(69) Different doors are installed on rolling stock, including for instance passenger access doors, internal doors and driver doors. The Parties’ activities overlap with respect to access doors and internal doors.

(70) In its recent decision in the case M.7538 – Knorr-Bremse / Vossloh, the Commission concluded that (access) doors for rail vehicles constitute a distinct market. The Commission further concluded that there was no need to segment the market according to, for instance, the type of rolling stock in question.15

6.5.1.2. The Notifying Party’s position

(71) The Notifying Party submits that the relevant market concerns either the manufacture and supply of all doors, or that distinct markets exist for (i) access doors and (ii) internal doors.

(72) With regard to access doors, the Notifying Party submits that the market concerns either the manufacture and supply of access doors for all different kinds of rolling stock, or that distinct markets exist according to the type of rolling stock in question, namely (i) high-speed trains, (ii) mainline and regional trains, (iii) (unengined) passenger coaches, (iv) underground trains and (v) light rail vehicles (‘LRVs’).

6.5.1.3. Results of the market investigation and the Commission’s assessment

(73) The results of the market investigation did not call in to question the Commission’s findings in M.7538 – Knorr-Bremse / Vossloh. As to technical differences between different types of rolling stock, rolling stock manufacturers overwhelmingly considered that different types of rolling stock require different solutions for their systems, including doors.16 However, rolling stock operators were more split on the question, though a clear majority of even them considered that high-speed trains have specific requirements.17

(74) The Commission notes that market participants’ market shares18 differ to some extent between access doors for different kinds of rolling stock with the exception of IFE / Knorr-Bremse, which is strong in all potential segments. Of the Parties, Faiveley achieves higher market shares in heavier rolling stock and particularly in high-speed trains while Wabtec concentrates on underground trains and LRVs.

6.5.1.4. Conclusion on product market definition

(75) Therefore, and considering all evidence available to the Commission, the Commission considers that a distinct market exists for the production and supply of doors for rolling stock. It can be left open whether this market should be further segmented as the outcome of the competitive assessment remains the same under all alternative market definitions.

6.5.2. Relevant geographic markets

(76) In its recent decision in the case M.7538 – Knorr-Bremse / Vossloh, the Commission found that the market was likely EEA-wide, though it did not conclude on the exact scope of the market.19

(77) The Notifying Party submits that the market(s) for train doors are EEA-wide.

(78) The results of the market investigation do not call into question the existence of an EEA-wide market.

(79) Therefore, and considering all evidence available to the Commission, the Commission considers that the market, including its potential sub-segments, is EEA-wide.

6.5.3. Access doors for underground trains

(80) The Transaction only gives rise to affected markets if the potential sub-segment of access doors for underground trains is considered in isolation. According to the Notifying Party, the Parties’ combined market shares remain below 20% under all other alternative market definitions. Moreover, Faiveley’s market shares have been in a constant decline: while Faiveley’s market share in access doors for all kinds of rolling stock was [40-50]% in 2005–2007, it decreased to [30-40]% in 2007–2009 and was down to [10-20]% in 2011–2014. Wabtec’s market share has remained more constant at less than [0-5]%.

(81) In the potential segment of access doors for underground trains, the Parties’ combined market share was [20-30]% in 2011–2014 (Wabtec: [5-10]%, Faiveley [10-20]%). Competitors include IFE / Knorr-Bremse ([50-60]%), Ultimate ([1020]%) and Gebr Bode ([0-5]%).20 Wabtec’s market share was mainly due to one project (Lille underground) that it won in 2012.

(82) The Commission notes that the Parties’ combined market share remains modest and that a number of notable competitors would remain on the market after the Transaction.

(83) In the market investigation, market participants were split as to whether the Transaction would have negative effects. Some market participants did refer to potential competition concerns related to, for instance, fewer remaining competitors. On the other hand, that view was not shared by all and, moreover, one market participant that was generally concerned indicated that it is already in discussions and in an approval process with a new entrant to access doors for underground trains.21

(84) Therefore, on balance and in light of the evidence available to it, the Commission considers that the Transaction is unlikely to give rise to a significant impediment to effective competition in the EEA with respect to train doors.

6.6. Friction brake systems for trains and their subsystems

6.6.1. Relevant product markets

6.6.1.1. Background and previous cases

(85) Brake systems are key safety systems of any train vehicle, and their basic function is to slow down or stop the train when required. There are a number of different technical solutions to achieve that function, such as friction brakes, magnetic brakes and dynamic brakes.

(86) The Transaction concerns friction/service brakes. They function by transforming the train’s kinetic energy into heat through the application of friction materials against a brake disc or directly on the wheel treads of a train vehicle. The main components of friction brake systems are (i) the bogie brake, which is the mechanical brake and can consist of disc brakes22 and/or tread brakes23, and (ii) a brake control system that manages the brake function through a pressure medium, which is either compressed air (pneumatic brakes) or a liquid (hydraulic brakes). Pneumatic systems also require (iii) an air supply unit (air compressor and air dryer).

(87) In its recent decision in case M.7538 – Knorr-Bremse / Vossloh, the Commission considered it likely that friction brake systems for rail vehicles constitute a distinct product market, separate from magnetic and dynamic brakes, and that friction brake systems could be further segmented by type of brake control system between

(i) pneumatic and (ii) hydraulic. The Commission though left the question ultimately open.24

(88) The Commission has previously also left open the question of whether there are separate markets on the one hand for complete brake systems and, on the other hand for their subsystems – that is the bogie brakes, brake control systems and, for pneumatic brakes, air supply units.25

6.6.1.2. The Notifying Party’s position

(89) The Notifying Party submits that the relevant market is the market for the manufacture and sale of complete friction/service brake systems for all types of rolling stock (OEM), with possible further segmentation, according to the type of rolling stock concerned, into brake systems for (i) high-speed trains, (ii) mainline and regional trains, (iii) locomotives, (iv) passenger coaches (un-engined), (v) underground trains, (vi) LRVs and trams, and (vii) freight cars.26 The Notifying Party notes that the potential segment for hydraulic brakes corresponds to that of LRVs and trams that generally employ such brakes in contrast to other types of rolling stock that generally use pneumatic brakes. The Parties’ activities in Europe do not overlap with regard to hydraulic brake systems or their subsystems as Wabtec does not supply those within the EEA.

(90) The Notifying Party submits that there are no distinct relevant markets for subsystems of friction brake systems as the majority of customers prefer to purchase brakes as complete brake systems: 95% of brakes for freight applications and 70– 80% for passenger applications are purchased as complete brake systems. The Notifying Party has nonetheless acknowledged that customers may request bids for subsystems only and that some smaller suppliers are only able to supply subsystems instead of complete friction brake systems. The Parties have provided information with regard to (i) bogie brakes and (ii) pneumatic brake control systems.

(91) The Notifying Party submits that a pneumatic friction brake system can be electronically controlled (‘electro-pneumatic friction brake system’) by an electronic brake control subsystem. The Notifying Party notes that customers in the EEA increasingly require such equipment, particularly in complex applications such as in high-speed, mainline and regional trains.

6.6.1.3. Results of the market investigation and the Commission’s assessment

(92) Friction compared to other brake systems: The replies to the market investigation support the view that friction/service brake systems constitute a distinct market from dynamic and magnetic brakes. In particular, a vast majority of respondents considered that friction brakes cannot be substituted by other types of brakes or that friction brakes will be needed in addition to other types of brakes for reasons of, for instance, safety.27

(93) Pneumatic compared to hydraulic brake systems: The majority of both train operators and rolling stock manufacturers considered that hydraulic and pneumatic systems are not substitutable for each other. Respondents were, however, particularly clear in that pneumatic systems cannot be substituted for hydraulic ones.28 The replies also generally supported the view that hydraulic brake systems find their main applications in LRVs and trams, though some respondents could consider pneumatic systems for those applications as well.29

(94) The Commission further observes that there are brake system suppliers that specialise in one or the other type of system, pneumatic or hydraulic, such as Hanning&Kahl for hydraulic systems. That fact supports the view that supply-side substitutability between hydraulic and pneumatic friction brakes may be somewhat limited.

(95) Brake systems in different applications: As to differences in brake systems between different types of rolling stock in general, rolling stock manufacturers tended to consider that brake systems in different types of rolling stock each have specific characteristics, though they also noted that many suppliers can supply friction brake systems for all or most applications.30 Train operators, on the other hand, were more split on the question of possibly different requirements regarding brake systems in different applications, although the majority of them replied that requirements in high-speed trains differ from those in other types of rolling stock.31

(96) Electro-pneumatic compared to pneumatic brake systems: Market participants confirmed that there are differences between electronically controlled and nonelectronic friction brake systems. While many respondents could consider both (non-electro) and electro-pneumatic brakes for many applications, including mainline and high-speed, they also saw issues and challenges with substitutability.32 In any event, replies to the market investigation indicated that the demand in passenger applications in the EEA is, for the most part, focused on electronically controlled (electro-)-pneumatic brake systems instead of (non-electro) pneumatic brake systems. Such systems bring numerous technical advantages, such as better reaction time and upgradebility.33

(97) Complete brake systems compared to subsystems: Finally, the majority of rolling stock manufacturers replied that they purchase both complete friction brake systems as well as their subsystems, which they then integrate into complete brake systems. Some, though not all, rolling stock manufacturers have also at least sometimes used the possibility of purchasing separate subsystems as a negotiation tool for getting better prices and conditions when purchasing complete friction brake systems.34

(98) With regard to the supply-side of brake subsystems, the Commission observes that there are market participants that only supply subsystems or even only one type of subsystem. For instance, Atlas Copco supplies air supply units but no other types of subsystems or complete friction brake systems.

(99) As regards bogie brakes in particular, a number of respondents indicated that disc brakes and tread brakes are not substitutable from the customers’ perspective, for instance because of brake performance considerations. It was also noted that changing between the types of bogie brakes once a rolling stock vehicle has been designed would require significant redesign effort.35

6.6.1.4. Conclusion on product market definition

(100) In light of the above, and considering all evidence available to the Commission, the Commission considers that a distinct market exists for the manufacture and supply of complete pneumatic friction brake systems (as opposed to other types of brakes and hydraulic systems). The market for complete friction brake systems is also likely at least differentiated between electronically controlled and non-electronically controlled systems, and it cannot be excluded that a further differentiation or segmentation could be made according to the type of rolling stock in question (highspeed, mainline and regional, and so on). The exact product market definition can nonetheless be left open as the result of the competitive assessment remains the same under all alternatives.

(101) In addition, the Commission considers that separate markets exist for the subsystems of pneumatic friction brake systems: bogie brakes, brake controls and air-supply units. For brake controls, similar consideration between electronic and non-electronic brake controls apply as for complete pneumatic friction brake systems. For bogie brakes, disc brakes and tread brakes likely constitute separate markets. The exact product market definitions can nonetheless be left open as the result of the competitive assessment remains the same under all alternative approaches.

6.6.2. Relevant geographic markets

6.6.2.1. Background and previous cases

(102) The Commission has previously considered the markets for train brake systems (and their spare parts) to be EEA-wide or at least EEA-wide, though it has ultimately left the exact market definition open in its most recent decision M.7538 – Knorr Bremse / Vossloh.36

6.6.2.2. The Notifying Party’s position

(103) The Notifying Party submits that the markets are at least EEA-wide. The Notifying Party acknowledges that its brake control system that is usable in the US cannot directly be used in Europe without redesign and homologation, and that the requirements for obtaining safety certificates for Europe are different than those for the Asian markets. In addition, acceptable prices for such products differ, at least between the US and Europe.

6.6.2.3. Results of the market investigation and the Commission’s assessment

(104) The responses to the market investigation support the finding of an EEA-wide market. While some trade may take place even globally, a number of rolling stock manufacturers replied that they can either only source from the EEA or that they source from the EEA even if they could in principle source from elsewhere. A number of market participants, though not the majority, considered there to be barriers to trade beyond the EEA, referring for instance to specific European norms.37

(105) Therefore, and considering all evidence available to the Commission, the Commission considers that the markets are EEA-wide.

6.6.3. Complete friction brake systems in the EEA

6.6.3.1. Framework for assessment

(106) The Parties’ activities in the supply of complete friction brake systems in the EEA only overlap with respect to the potential subsegment of freight cars. This application typically calls for more simple brake solutions compared to passenger trains. However, the Transaction would not give rise to affected markets with respect to this potential subsegment as the Parties’ market share remains below 20%, and it is not discussed further in this Decision.38 The same applies if assessing all complete brake systems together regardless of the type of rolling stock they are destined for.

(107) With respect to complete friction brake systems for passenger applications, the Parties' activities do not overlap in the EEA since Wabtec is currently unable to offer complete electro-pneumatic friction brake systems on which the EEA-demand focuses (see Recital (96)).39 Nonetheless, the Commission raised doubts in its Article 6(1)(c) Decision regarding the elimination of Wabtec as a potential competitor in the EEA market for complete friction brake systems (for non-freight applications). Indeed, elements discovered in the Phase I investigation indicated that Wabtec was a potential entrant into the EEA market.

(108) In accordance with the Commission Guidelines on the assessment of horizontal mergers under the Council Regulation on the control of concentrations between undertakings40 (‘Horizontal Merger Guidelines’), a merger with a potential competitor can have horizontal anti-competitive effects in two situations: (i) when the potential competitor already significantly constrains the behaviour of the firms active in the market or (ii) it is likely to enter the market in a relatively short period of time after which it would constrain the behaviour of firms currently active in the market.41

(109) What constitutes an appropriate time period depends on the characteristics and dynamics of the market, as well as on the specific capabilities of the potential entrant.

(110) For the merger to have significant anti-competitive effects, two basic conditions must be fulfilled. First, the potential competitor must already exert a significant constraining influence or there must be a significant likelihood that it would grow into an effective competitive force. Evidence that a potential competitor has plans to enter a market in a significant way could help the Commission reach such a conclusion. Second, there must not be a sufficient number of other potential competitors, which could maintain sufficient competitive pressure after the merger.42

(111) In this context the Commission notes that the time periods considered may be different when the potential entrant is one of the merging Parties compared to the situation where a third party entry may be considered as a constraining factor on the merged entity’s market power.43 As such, the two-year period referred to in the Horizontal Merger Guidelines as the normal threshold relates to situations where the Commission has to assess whether entry by a third party would be sufficiently swift and sustained to deter or defeat the exercise of market power by the merged entity.44

6.6.3.2. Structure of the market

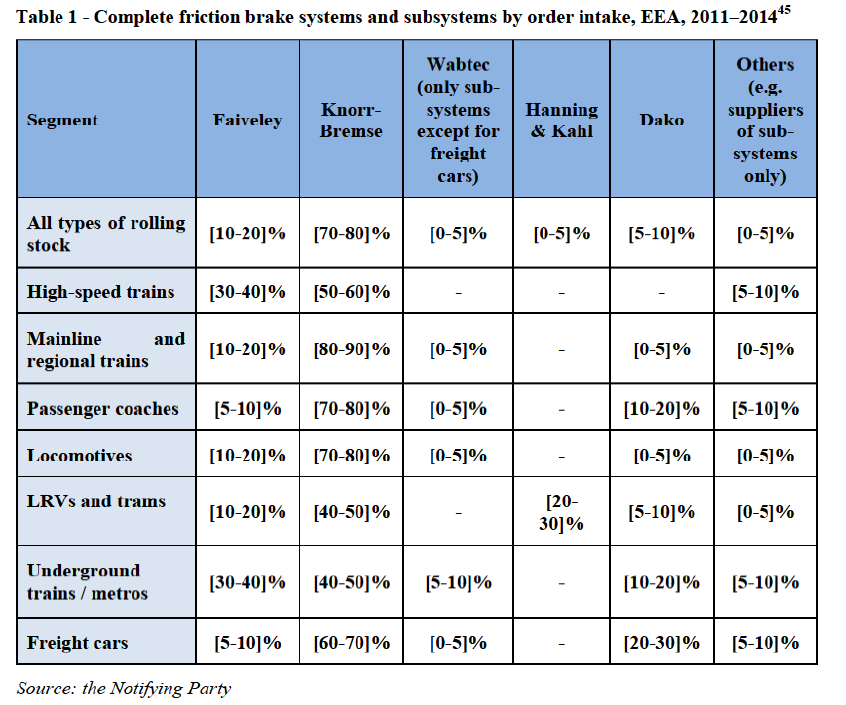

(112) Knorr-Bremse is a clear market leader for complete friction brake systems in the EEA with Faiveley as the number two in the market. Together, those two market players have a combined market share in all complete brake systems of [80-90]%, and they are even stronger at the high-end of products for high-speed, mainline and regional trains where their combined market shares are [90-100]% (the figures include also sales of subsystems that the rolling stock manufacturers have integrated into complete brake systems). The remainder of the market share is shared between smaller market players. The shares of various suppliers by order intake and type of rolling stock provided by the Notifying Party are listed in Table 1.

(113) The current market structure is in line with the Notifying Party's argument that only Faiveley and Knorr-Bremse are currently able to supply complete electro-pneumatic brake systems suitable for Europe, and that such systems (in contrast to purely pneumatic systems) are a de facto standard requirement in most European passenger train projects except those for LRVs and trams that use hydraulic systems. Therefore, at present only Faiveley and Knorr-Bremse effectively compete for the new friction brake projects where the brake manufacturer is expected to supply the complete friction brake system and not sub-systems only.

(114) The situation appears broadly similar even when looking at the different potential segments of the market. However, in the potential segment for LRVs and trams, the market structure is different. That is mainly due to the presence of one other significant competitor in that segment, Hanning & Kahl. Hanning & Kahl concentrates on hydraulic brake systems, which are used in LRVs and trams (as opposed to other types of rolling stock that typically are equipped with pneumatic brakes).

(115) Historically, the market structure was relatively stable between 2005 and 2011: Faiveley’s market share remained at [30-40]% for all of the three periods 2005–2007, 2007–2009 and 2009–2011 (when considering brakes for all types of rolling stock together). However, in 2011–2014 it fell to [10-20]%. According to Faiveley, the drop has been due to the temporary execution problems it had in some of its major projects with the main European rolling stock manufacturers.46 That being said, market participants have in general not questioned Faiveley’s technological capabilities. A market participant explains: ‘- - has barely seen any applications for which Faiveley was not able to offer a technologically compliant solution.’47

6.6.3.3. The Notifying Party’s position

(116) Wabtec explains that, except for freight cars, it is unable to supply complete friction brake systems in the EEA. In particular, it does not have in its product portfolio the kind of electro-pneumatic brake systems that are needed in the EEA but can only supply (non-electro) pneumatic friction brake systems there. That is in contrast with Faiveley and Knorr-Bremse, both of which have such a product.

(117) Wabtec further submits that there is no significant likelihood that it would become an effective complete friction brake system supplier for non-freight applications in the EU ‘in a relatively short period of time’. Barriers to entry are high and it would take Wabtec at least 4–6 years before it could develop even one of the subsystems needed, namely electro-pneumatic brake control. Wabtec should therefore not be considered as a potential competitor for the supply of complete brake systems for all types of rolling stock in the EEA.

(118) Wabtec clarifies that it is missing three main components (of European standard); in order to be able to offer complete electro-pneumatic brake systems in Europe, it would need (i) an electronic brake control that is a de facto requirement in new European non-freight train projects, (ii) an electronic driver’s brake valve and (iii) an oil-free air-supply unit.

(119) However, Wabtec acknowledges that it has been pursuing entry into the European market for complete electro-pneumatic friction brake systems. It has worked on two different projects aiming at developing a complete integrated electronic brake control system that could also be offered in the EEA: [...]. Wabtec clarifies that it has no plans or development programmes in place to develop [...].

[...]

(120) [...] is a development project for a new integrated, compact and modular brake control system that Wabtec initiated at the end of [...]. The system's development has been carried out as a [...] the product itself was initially intended to be used [...], including in Europe (though not specifically targeted there), [...].

(121) However, engineers at Wabtec's European subsidiary Poli soon realised that [...] could not be used in Europe without significant technical redesign: the product was too expensive, too sizeable and too heavy. A comparison of [...] size and weight to existing competing products is provided in Table 2.

(122) Size is particularly important in the EEA market as customers increasingly require electro-pneumatic brake control units that can fit in a contained space (for instance, under a seat) so as to not sacrifice profitable passenger space.

(123) Furthermore, maintaining and servicing [...] would be more complex and expensive for the train operator than servicing competitors' products: while most of the competitors' products constitute minimum line replaceable units `MLRUs' that can easily be removed and replaced as a single unit and often by one serviceman, the design and weight of [...] requires a more complex disconnection and replacement procedure, and the weight of the product requires more than one person to handle it. This will typically mean that [...] needs to be serviced and repaired on the train. That is a disadvantage compared to the typical European approach that is to detach a faulty unit and replace it with another one while the original one is sent for repairs at a specialised shop, thus allowing for the train to return to commercial service quicker and needing less trained personnel at the train depot.

(124) [...]

(125) [...] was also found to be at a cost disadvantage compared to competitors' available solutions in the EEA. This is the result of [...]. To address the lack of cost-competitiveness of [...], Wabtec envisaged in [...] developing a new version of [...],. The [...1 is essentially a cost reduction exercise, aimed at bringing [...] into price range that is acceptable for instance in the European market [...]. However, Wabtec submits that its European engineers found that [...] was not adequate to make [...] suitable for Europe [...].

(126) Wabtec further explains that [...1. A capital allocation request (CAR') of [...1, which included costs related to the European market, was internally rejected. [...1 the [...] project has since continued without developments for Europe.

(127) Therefore, Wabtec submits that [...1 is not technically or commercially suitable for the EEA market. Moreover, even if Wabtec decided to continue with the development of [...], it would take 4 to 6 years to finish. The timetable for [...] submitted by Wabtec is included in Table 3.

[...]

(128) [...] is an alternative project to [...] that Wabtec's European ann started to explore

[...].[...] is designed to be more modular and integrated than [...1. [...] is also designed as an MLRU, providing the ease of servicing seen in competitors' products but not in [...].

(129) [...] project is managed by Wabtec's [...]. Wabtec's group management accepted a CAR mandating further development of E...] in E...].

(130) According to Wabtec, [...] still requires significant development [...1. The development status of [...] is presented in Table 4.

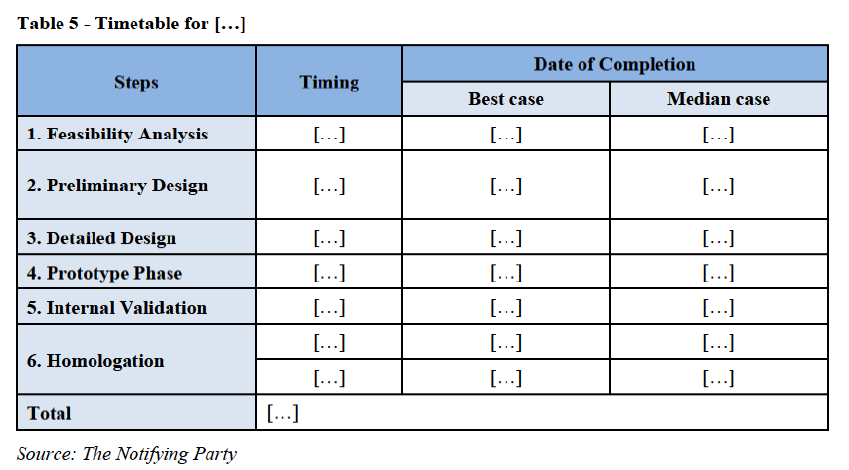

(131) Wabtec submits that the development of [...] will take 4 to 6 years to complete from the beginning of the development process. Under the best case scenario, the product E...]. The timetable for [...] submitted by Wabtec is included in Table 5.

Electronic driver's brake valve and air-supply units

(132) Wabtec submits that, even if it had an electronic brake control product, it would still need a European-standard (i) electronic driver's brake valve and (ii) oil-free air-supply unit to be able to offer complete friction brake systems in the EEA. Wabtec puts forward that it does not have development programmes related to those products. According to Wabtec, its development strategy is [...]. Moreover, Wabtec's existing EU-compliant pneumatic driver's brake valve could be used to participate in some tenders for underground as well as mainline and regional trains in the EU.

(133) With respect to an electronic driver's brake valve for Europe, Wabtec clarifies that an electronic driver's brake valve is required on approximately 60% of the brake systems supplied to EEA customers. Moreover, even if non-electronic driver's brake valves could be used in some less demanding applications, such as fixed-configuration regional trains, the pneumatic product Wabtec has [...] does not meet EEA customers' expectations [...].

(134) Wabtec submits that it lacks the necessary [...] to develop an electro-pneumatic driver's brake valve for the EEA; [...]. Wabtec estimates that the development would cost approximately [...1 and take approximately 4 to 6 years [...1. Therefore, [...], the product could be ready and homologated only in [...].

(135) Wabtec submits that it would not be able to procure the required electronic driver's brake valve from third parties as only Knorr-Bremse and Faiveley have such products, and they are not willing to supply other brake manufacturers.

(136) As regards air-supply units, Wabtec explains that it currently does not have a suitable product meeting the EU requirements. Wabtec has suitable products, including oil-free air-supply units, meeting the US standards but, according to Wabtec, those products are not suitable for use in Europe because of differences in technical requirements. Wabtec estimates that it would cost EUR [...] and take 4 to 6 years for it to develop and homologate an oil-free compressor that meets the European requirements. Therefore, the product would be ready and homologated the earliest

(137) Wabtec submits that it could only procure a partial solution from third parties when it comes to air-supply units. In particular, Wabtec could not procure EU-compliant oil-free compressors as such products for rail applications are not available on the market.

Wabtec considers it needs homologated products

(138) With regard to the development times, Wabtec explains that it is necessary to have a complete and homologated product ready before it can be taken seriously by customers and win any projects. That being said, Wabtec has taken part in a number of tenders in Europe during 2012–2015 that concerned complete brake systems for trains destined to be operated in Europe. Wabtec failed to win any of them. According to Wabtec this was, on many occasions, because it did not have a homologated and service proven system available. At present, Wabtec does not have any projects with any actual or potential customer in the EEA with a view to supplying complete electro-pneumatic brake systems to these customers, or developing such systems with them.

(139) Wabtec notes that it regularly discusses the supply of complete brake systems for Europe with some rolling stock manufacturers, including [...]. Wabtec has nonetheless so far failed to convince them to seriously consider it as a complete brake system supplier in the EEA in the short term. [...].49

6.6.3.4. Faiveley’s new generation of brake control products

(140) In the course of the Phase II investigation, Faiveley disclosed to the Commission that it has been developing a new generation of brake control products, which it plans to launch commercially in the Innotrans fair in Germany in September 2016. The new products are known as Metroflexx [...]. The new generation of brake control products will succeed Faiveley’s current products, such as the EPAC product line that was initially developed between 1999 and 2003.

(141) According to Faiveley, the new products offer significant technical advancement compared to their predecessors. [...]

(142) Faiveley estimates that the total manufacturing cost for a Metroflexx control unit is [...] while the current products it is to succeed cost [...] per unit to produce depending on the model.

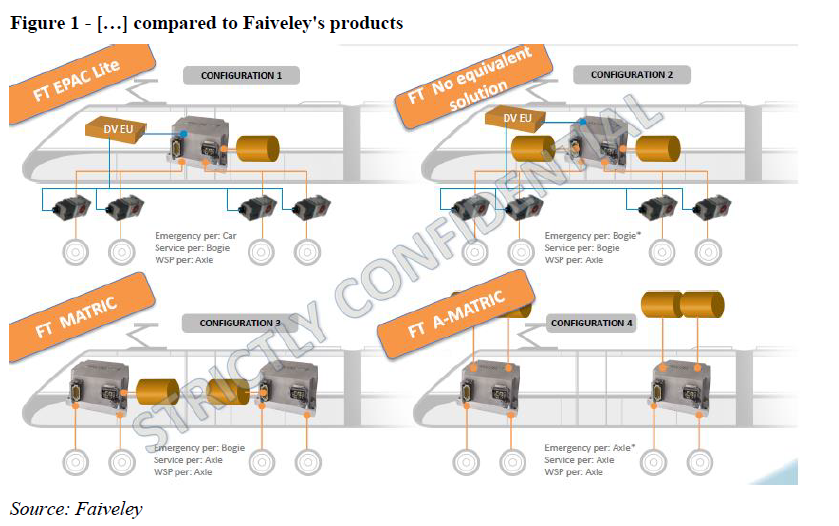

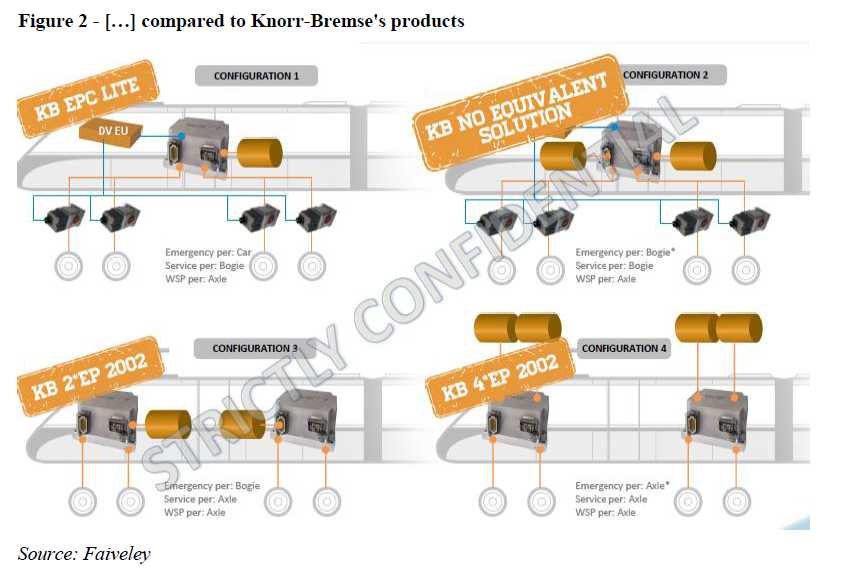

(143) Faiveley adds that the new products also provide for functionalities that enable new brake configurations that require a smaller number of control units per rolling stock car than before. In practice, in some configurations where Faiveley’s and Knorr-Bremse’s current products require two to four control units per rolling stock car, the new product will require one or two. That further reduces costs of the brake control units in a set of configurations. For illustration, a comparison of Metroflexx and Faiveley’s and Knorr-Bremse’s current products are depicted inFigure 1 and Figure 2. The benefits compared to the current products are shown in configurations 2 and 4 in the Figures.

(144) The new Faiveley products have been designed as minimum line replaceable units that can easily be removed and replaced. Given their lower weight and smaller dimensions, they are easier to handle during maintenance compared to their predecessors or to competitors’ current products.

(145) Finally, Faiveley explains that the products are retro-compatible in the sense that they are interchangeable with limited adaptations with Faiveley’s existing brake control units. That will provide train manufacturers a level of comfort when switching to a new product: should problems arise with the new control product, they can easily be replaced with the previous, service-proven products (though the benefits, such as new brake configurations, would be lost).

6.6.3.5. Results of the market investigation and the Commission’s assessment

Wabtec is missing an electro-pneumatic brake control system in the EEA

(146) The Commission observes that Wabtec’s internal documents support its submission that it is not at present capable of supplying competitive complete electro-pneumatic friction brake systems for non-freight trains to be used in Europe. In light of the internal documents, the key subsystem missing from Wabtec’s portfolio is the electronic brake control that Wabtec has been developing in its [...] projects.50

(147) Nonetheless, the Notifying Party has claimed that even if it had the electro-pneumatic brake control, it could not offer complete electro-pneumatic friction brake systems in the EEA as it would still miss two other important components: (i) an EU-compliant electronic driver’s brake valve and (ii) an EU-compliant oil-free air-supply unit. The Notifying Party has submitted it has no on-going projects to develop those subsystems and that it does not even have EU-compliant equipment to test an electronic driver’s brake valve during development.

(148) For the reasons set out in recitals (149) to (152), the Commission has doubts about the Notifying Party’s arguments related to electronic driver’s brake valve’s and air-supply units.

(149) First, it seems highly unusual for a company to spend time and money developing one missing part of a complete brake system but to have no concrete plans or projects to develop the other missing parts.

(150) Second, Wabtec’s internal documents suggest that Wabtec [...]51 [...]52 While Wabtec has explained that these discussions only relate to the pneumatic parts of the driver’s brake valve, the Commission considers that [...] with respect to an electronic driver’s brake valve within Wabtec. It is nonetheless unclear how advanced that development is.

(151) Third, replies to the market investigation purport that an electronic driver’s brake valve may not even be absolutely necessary for a complete electro-pneumatic friction brake system. In particular, market respondents have indicated that this is not necessarily required as there are other technical means to operate the brakes or that many solutions exist in the market.53

(152) Fourth, while the results of the market investigation support the view that oil-free air-supply units have indeed become the de facto standard in new European rolling stock projects,54 they do not support the Notifying Party’s submission that suitable oil-free air-supply units would not be available from third parties for train applications. Instead, the results show that such systems are currently available at least from Atlas Copco that is also currently supplying them to the train industry,55 and that another supplier is in the process of expanding its product portfolio to cover suitable oil-free products.56

(153) Therefore, the Commission considers that there is some evidence that Wabtec could produce a complete friction brake system suited for the EEA as soon as it has a suitable electro-pneumatic brake control system available. However, it is not necessary to conclude on this question as the outcome of the competitive assessment does not depend on it.

It is likely that [...] would not be competitive in the EEA

(154) Wabtec has been developing a new integrated electro-pneumatic brake control system known as [...]. Wabtec nonetheless submits that the [...] is not suited for the European market and would require significant redesigning before it would technically and commercially be suitable and viable in Europe.

(155) The Commission notes that [...] has been developed in a US-led global project. Wabtec’s internal documents suggest that the specific requirements of the European market [...].57

(156) For the reasons set out in recitals (157) to (162), the Commission considers that [...] is not technically and commercially suited for the European market and that it is unlikely that it could be used to build a competitive complete friction brake system for the EEA at present.

(157) First, [...] than competitors’ EEA products. [...] could not, for instance be [...]. A market participant describes: ‘[t]he overall design of [...] platform is in certain respects comparable to [...] although not yet at the same level considering functionalities and packaging’.58 Wabtec’s internal documents confirm that Wabtec internally considers such physical characteristics to be serious shortcomings for [...] from a European perspective.59

(158) Second, [...] maintenance costs are likely to be higher than those for competitors’ products. Unlike for instance Faiveley’s products, [...] is not designed as an MLRU but removing and replacing it requires considerably more work if that is to be done instead of troubleshooting and servicing the unit on the train. Moreover, the weight of a [...] unit it makes its handling during maintenance and repairs more difficult than handling the significantly lighter competitors’ products (see Table 2). These reasons are likely to result in [...] requiring longer maintenance brakes for the rolling stock that will be out of commercial service during such times.

(159) Wabtec’s internal documents support the view that [...] is inferior in terms of [...], suggesting that Wabtec internally considers [...] to be a weakness.60 The Commission also understands train operators to be considerate of operating and life-cycle costs when procuring new rolling stock.61

(160) Third, [...] is significantly more costly to produce than competitors’ products. Wabtec has in its internal documents estimated that [...] compared to [...] products in a comparable set-up and considered that it would need to [...].62 Information from Faiveley’s internal documents support the view that [...].63 Wabtec has considered reducing the costs of [...].

(161) Fourth, the evidence available to the Commission suggest that Wabtec is internally doubtful of [...] being suitable for or competitive in the European market. Doubts have been cast internally in senior management about the weight, size and cost of [...], and it has also been suggested that it would eventually arrive too late.64

(162) Fifth, [...]. Therefore, while some market participants have considered it likely that Wabtec might at some point offer a complete electro-pneumatic friction brake system in the EEA and have in general welcomed the idea,65 they may not have been aware of the actual status and situation of [...]. The Commission thus considers that, in the absence of evidence to the contrary, it cannot be excluded that Wabtec has presented [...] which may have affected market participants’ views about [...].

(163) Therefore, and in the light of all evidence available to it, the Commission considers it unlikely that Wabtec could effectively enter the EEA market for complete friction brake systems with [...] as it stands at present.

(164) Wabtec has envisaged a development programme to address [...]. According to Wabtec, it would take it at least [...] to complete that project and the project would be finalised in [...].[...] would thus arrive [...] Wabtec’s alternative brake control product (see Table 5).

(165) Further, the Commission notes that even if Wabtec addressed the cost side of [...], that would not address all the technical and life-cycle cost deficiences of [...]. It is thus highly doubtful that [...] would be competitive in the EEA without further technical redesign.

Wabtec’s alternative project: [...]

(166) [...] is Wabtec’s alternative project to overcome lack of an electro-pneumatic brake control system in the EEA. Wabtec’s internal documents suggest that it was originally intendend as [...].66

(167) The [...] project is managed by Wabtec’s European arm, initially without [...]. However, Wabtec accepted a CAR for the development of [...] in [...]. The CAR was accepted to facilitate possible remedies discussions with the Commission if the latter maintained competition concerns related to complete friction brake systems.

(168) According to Wabtec, it is aiming at [...] in line with competitors’ products. Moreover, [...] seen in competitors’ products but not [...]. It would thus probably not be significantly inferior to the competitors’ present products in terms of cost.

(169) The Commission notes that [...] is in the early stages of development. [...]. However, [...]. The product thus still requires significant design effort as well as all testing and homologation, which has not begun and could not begin in the present state of development.

(170) The evidence available to the Commission does not allow it to call the project timetable submitted by Wabtec (see Table 5) into question. Wabtec’s internal documents state, for instance that [...]67. The CAR funding [...] further development was approved internally in Wabtec [...]. Therefore, even if [...], it appears that the product could not be fully completed and homologated until [...].68

(171) Concerning the time it would take Wabtec to enter the market, Wabtec has submitted that it could only be successful once it has a fully completed and homologated brake system to offer. However, a number of market participants responding to the market investigation disagree with that statement. Instead, a number of major rolling stock manufacturers replied that they would consider a brake system that is not fully homologated at the moment of placing the bids, given that there is a time lag between tendering and awarding the contract and the actual implementation of the project. Similarly, some train operators, including major ones, also replied that they would consider a bid even if the brake system was not fully completed and homologated at the moment of placing the bids for new rolling stock.69

Timeliness of an entry by a potential entrant

(172) Concerning the time within which an entry by Wabtec would need to take place for it to be relevant in the merger assessment, the Commission recalls that the time periods considered may be different when the potential entrant is one of the merging parties compared to the situation where a third party entry may be considered as a constraining factor on the merged entity’s market power.70 Furthermore, what constitutes an appropriate time period depends on the characteristics and the dynamics of the market.71

(173) In the present case, the Notifying Party has submitted that the barriers to entry are high. That submission has been supported in the market investigation by market participants, citing for instance necessary R&D investments and homologation requirements.72 Rolling stock manufacturers and train operators are not aware of any entry into the EEA market for electro-pneumatic friction brake systems during 2011-2016 (except for one rolling stock manufacturer naming Wabtec).73

(174) It further appears that development periods for new products in the market are long. That finding is supported by the fact that Wabtec considers its development efforts to take significant time despite the fact that it has been pursuing an entry already for a number of years. It is also supported by the development times Faiveley has faced with its brake control products.

(175) In addition, product life in the market spans a considerable number of years. For instance, Faiveley’s new product line is intended to replace a previous product line whose first product (EPAC) was introduced in 2004; that is 12 years ago. The product life time is thus considerably longer than, for instance, in fast-moving consumer goods.

(176) In these conditions, the Commission considers it appropriate not to limit its assessment to a few years following the Transaction. Therefore, even an entry by Wabtec by 2019–2020 is, in principle, relevant in the context of the markets at issue.

Technological development in the market is dynamic

(177) The Commission recalls that, for the merger to have significant anti-competitive effects the potential competitor must either already exert a significant constraining influence or there must be a significant likelihood that it would grow into an effective competitive force.74

(178) When opening the proceedings and adopting the Article 6(1)(c) Decision, the Commission was under the impression that the market for complete friction brake systems was technologically mature and it was only aware of limited incremental technical developments introduced in the market. The question thus appeared to be whether Wabtec could reach the technological and commercial level existing in the market at present.

(179) However, during the Phase II investigation, Faiveley disclosed to the Commission that it has been developing a new product line to replace its present electro-pneumatic brake control solutions. The first products to be launched are known as Metroflexx and [...].

(180) The Commission notes that Faiveley’s new product line appears to include considerable technical innovation compared to its existing products, for instance in terms of [...] the first such major innovation from Faiveley since it launched its current product line that was initially developed [...]. The new product could also be produced at significantly lower costs than Faiveley’s current products. With a targeted unit cost of [...]. In addition, in some configurations, fewer control units would be required compared to the present products.

(181) The Commission notes that the production cost of Faiveley’s new products would be significantly lower than that of [...].

(182) The Commission further notes that the new products of Faiveley are significantly more advanced in their development process than any of the products Wabtec is developing. Faiveley has already indicatively offered the new products for sale, and it expects to launch the product commercially at the Innotrans fair in Berlin in September 2016.75

(183) Faiveley has presented the new product to a number of rolling stock manufacturers, either in 2016 or in 2015 when the product was still in an earlier stage of development and was known under the name [...]. The rolling stock manufacturers have generally expressed positive views about the new product even if they have been cautious, pending further information on the product. Retro-compatibility of the new product was viewed positively and as a potential way to facilitate faster market entry – [...]. 76

(184) The Commission considers that the introduction of such a new product by Faiveley shows that the market is experiencing technological development that is not only incremental. Such technological and commercial development is likely to make an entry by new entrants, such as Wabtec, even more challenging. It also appears more likely than not that [...] (as it is now developed) would be rendered outdated or at least significantly disadvantaged even before being launched. A product such as [...] would also not enjoy any benefits relating to retro-compatibility in the development and product launch phase.

(185) The Commission observes that Faiveley’s new products target [...]; that is the large but technically less demanding end of the rolling stock markets. However, the Commission notes that [...] constitute a significant share if not the majority of the total market. They are also more likely entry points to the market – including for Wabtec – than, for instance, the technically more demanding high-speed segment. The importance of Faiveley’s new products for the assessment cannot thus be brought into question because they do not at this stage address all possible segments of the market.

(186) While it cannot be excluded that Wabtec could eventually develop a product that is on par with Faiveley’s [...] Metroflexx products – Wabtec has significant financial and R&D resources – it is unclear in what time it could achieve that. Having already established that, given the particular characteristics of this market, an entry by Wabtec by 2019–2020 with a product like [...] is, in principle, relevant in the context of the markets at issue, the Commission nonetheless considers it apparent that Wabtec could likely not develop a product on par with Faiveley’s [...] and Metroflexx products in the same time frame. Given that uncertainty, it can also not be excluded that Faiveley or the clear market leader Knorr-Bremse could by the time Wabtec achieves the level of [...] Metroflexx have already moved a step further still in their technical and commercial offering.

Wabtec is currently not exercising significant constraints on the market

(187) The Commission recalls that a merger with a potential competitor can also have anticompetitive affects if the potential competitor already significantly constrains the behaviour of the firms active in the market.77

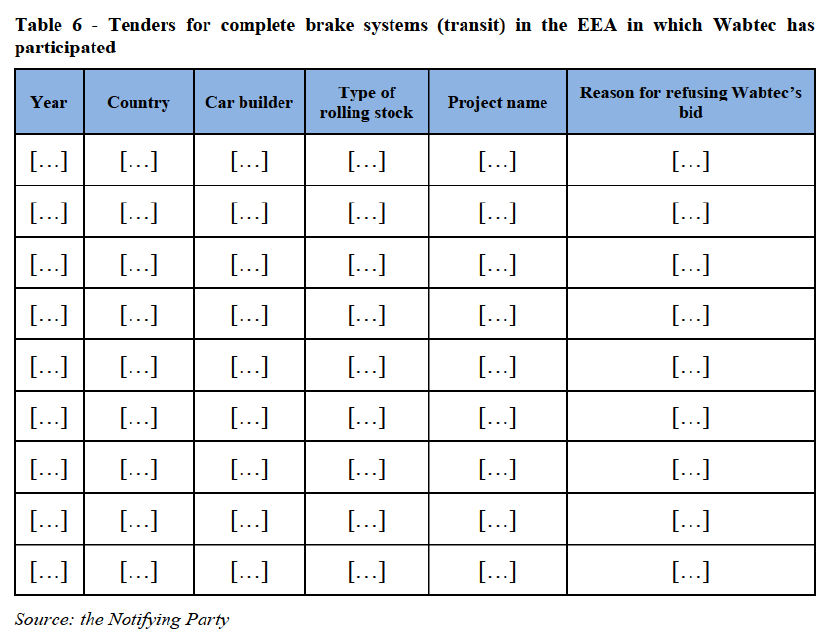

(188) To this effect, the Commission notes that Wabtec has, in the past, participated in tenders, though not winning any, even if it has not had an EEA-suited complete friction brake system available. The tenders in which Wabtec has participated and the reason why it considers it has been refused are included in Table 6.

(189) The Commission notes that while it cannot, in principle, be excluded that participation by Wabtec in those tenders could have had a constraining effect on the suppliers present in the market for complete friction brake systems in the EEA, the Commission has not found evidence showing any significant effect. To the contrary, a major market participant explained during the market investigation that `Wabtec's attempted entry into complete brake systems in the EEA so far has had no effects on price or on the behaviour or Faiveley or Knorr-Bremse'.78

(190) The Commission has also investigated Faiveley's internal documentation to determine whether Faiveley's decision to develop [...] Metroflexx has been influenced by Wabtec's activities or whether the new products have been intended to frustrate Wabtec's entry plans. The Commission has not found any such evidence. Rather, the evidence shows that Faiveley's development of new products has been [•••]•79

Sub-systems exert competitive pressure on complete brake systems

(191) The Commission recalls that, for a merger with a potential competitor to have anticompetitive effects, there must not be a sufficient number of other potential competitors, which could maintain sufficient competitive pressure after the merger.80

(192) The only significant suppliers of complete friction brake systems currently present in the EEA appear to be Faiveley and Knorr-Bremse. While some market participants considered that there could be entrants other than Wabtec (in addition to Faiveley and Knorr-Bremse), none of the respondents could name any entrants that would be certain to enter and would have technologies independent of Knorr-Bremse and Faiveley.81 Similarly, while some rolling stock manufacturers considered that they would seek new competitive opportunities, none of them named any market participant they could sponsor to enter the market.82 Furthermore, the majority of rolling stock manufacturers did not consider they could self-supply complete friction brake systems.83

(193) However, the Commission recalls that the majority of rolling stock manufacturers replied in the market investigation that they purchase both complete friction brake systems as well as their subsystems, which they then integrate into complete brake systems. Some, though not all, rolling stock manufacturers have also at least sometimes used the possibility of purchasing separate subsystems as a negotiation tool for getting better prices and conditions when purchasing complete friction brake systems.84

(194) Therefore, it appears likely that some level of competitive constraint is derived from the possibility of integrating complete friction brake systems by the rolling stock manufacturers, in particular from combining mechanical bogie brakes and air supply units purchased from third parties with the rolling stock manufacturer’s electronics. This is evidenced by the fact that Dako has supplied brake sub-systems for trains in the EEA to Stadler and Siemens for LRV and underground applications respectively.85 Similarly, Wabtec supplied all the elements of a complete electro-pneumatic friction brake system except for the electronics [...].86

(195) The Commission notes that air-supply units and mechanical bogie brakes are available from subsystem suppliers independent of Faiveley and Knorr-Bremse. For instance, Atlas Copco87 supplies air-supply units while Dako supplies mechanical bogie brakes. The supply of air-supply units is discussed more in detail in Section 6.6.4.4 and the supply of mechanical bogie brakes is considered in more detail in Section 6.6.4.2.

6.6.3.6. Conclusion on complete friction brake systems

(196) When initiating the proceedings and adopting the Article 6(1)(c) Decision, the Commission was concerned that the Transaction was essentially a three-to-two merger with Wabtec being a potential entrant into the market where only Faiveley and Knorr-Bremse were present.

(197) As explained in the Section 6.6.3.5, the Phase II investigation has cast doubts over Wabtec’s ability to make an effective entry within a relatively short period of time88 into the market which is experiencing dynamic technological development that is not only incremental.

(198) In the market investigation, some market participants have expressed concerns related to the Transaction, noting for instance that ‘reduced competition, back to 2 players only’, ‘less competition, increased prices’89 and ‘the only full scope alternative is Knorr-Bremse - - we do not consider this adequate alternative’.90 Nonetheless, some market participants have in contrast considered that an entry by Wabtec would not make a significant impact on the market or that the Transaction would help make Faiveley a more efficient competitor against the incumbent Knorr-Bremse. They have noted, for instance that ‘ - - believes that Faiveley could become a stronger competitor of Knorr-Bremse after a merger with Wabtec, due to its improved financial competitiveness - - believes that Faiveley together with Wabtec could force Knorr-Bremse to lower its prices’ and that ‘[t]he merger could potentially bring additional financing for R&D’91

(199) Therefore, on balance and in light of the evidence available to it, the Commission considers that in this particular case, the evidence available is not sufficient to establish to the requisite standard that Wabtec would already have significant constraining influence on Faiveley and Knorr-Bremse in the supply of complete friction brake systems in the EEA or that there would be a significant likelihood that Wabtec would grow into an effective competitive force following an entry into the market in a relatively short period of time.

6.6.4. Brake subsystems

6.6.4.1. Introduction

(200) The subsystems of a complete pneumatic or electro-pneumatic brake system are

(i) mechanical brakes, (ii) brake controls and (iii) air-supply units.